Graphene formaldehyde-removing floor wax

A technology of graphene and floor wax, which is applied in the direction of wax coatings, coatings, paints containing biocides, etc., can solve the problems of excessive formaldehyde content and affect the health of users, so as to improve wear resistance and anti-skid performance, and improve photocatalysis The effect of reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

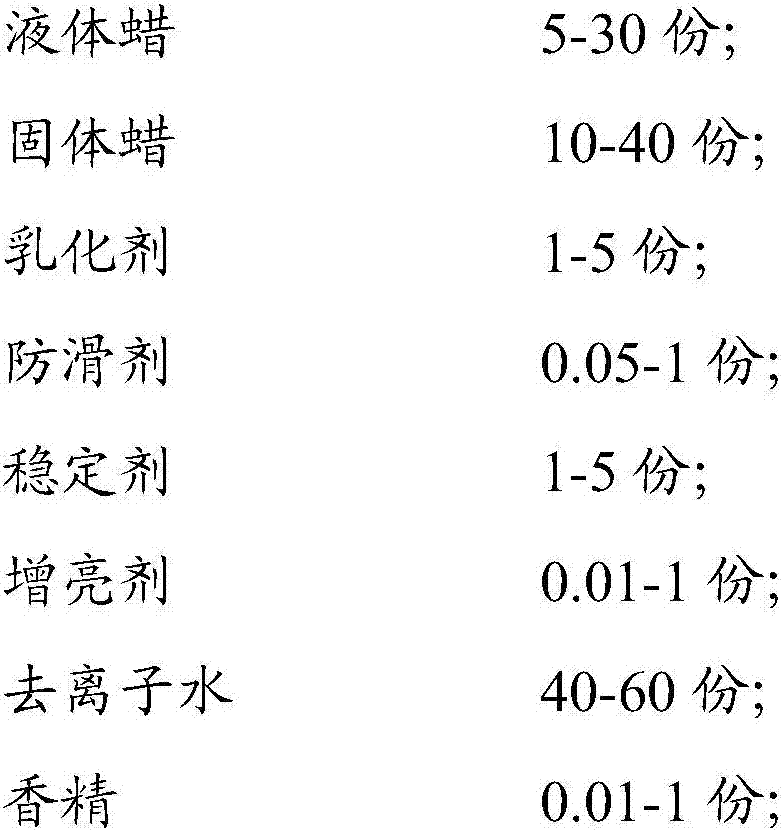

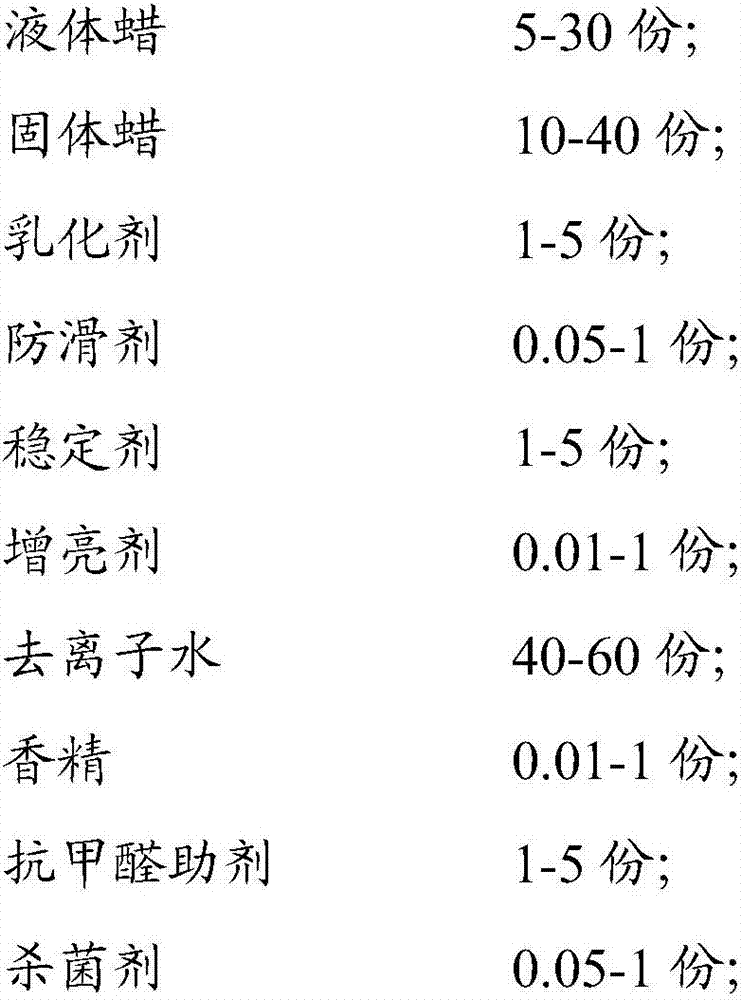

Method used

Image

Examples

Embodiment 1

[0019] A kind of graphene dealdehyde floor wax, it is characterized in that, each component of raw material is divided into as follows according to weight: 20 parts of aqueous polyethylene wax emulsions, 20 parts of paraffin wax, Span-602 parts, Tween-603 parts, rosin 0.5 part, 3 parts of triethanolamine, 0.05 part of silicone oil, 50.39 parts of deionized water, 0.01 part of essence, 1 part of anti-formaldehyde additive, and 0.05 part of fungicide. Prepare floor wax 1.

Embodiment 2

[0021] A kind of graphene dealdehyde floor wax, it is characterized in that, each component of raw material is divided into as follows according to weight: 10 parts of water-based polyethylene wax emulsions, 10 parts of water-based beeswax emulsions, 10 parts of solid paraffin, 20 parts of solid insect wax, Span- 602 parts, Tween-803 parts, 0.5 parts of rosin, 5 parts of triethanolamine, 0.05 parts of silicone oil, 36.39 parts of deionized water, 0.05 parts of essence, 3 parts of anti-formaldehyde additives, and 0.01 parts of fungicide. Prepare floor wax 2.

Embodiment 3

[0023] A kind of graphene dealdehyde floor wax, it is characterized in that, each component of raw material is divided into as follows according to weight: 5 parts of water-based polypropylene wax emulsions, 10 parts of water-based paraffin wax emulsions, 20 parts of solid white wax, 3 parts of Span-802, 3 parts of Tween-802 0.5 parts of rosin, 3 parts of zinc stearate, 1 part of silicone oil, 49 parts of deionized water, 0.5 parts of essence, 5 parts of anti-formaldehyde additives, and 1 part of fungicide. Prepare floor wax 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com