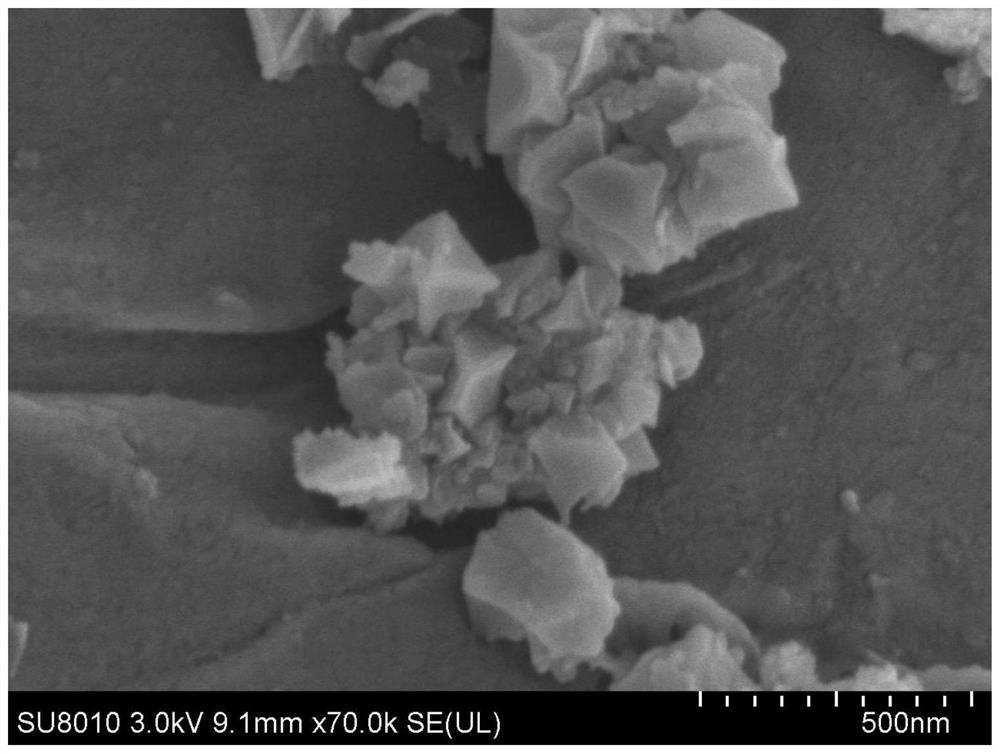

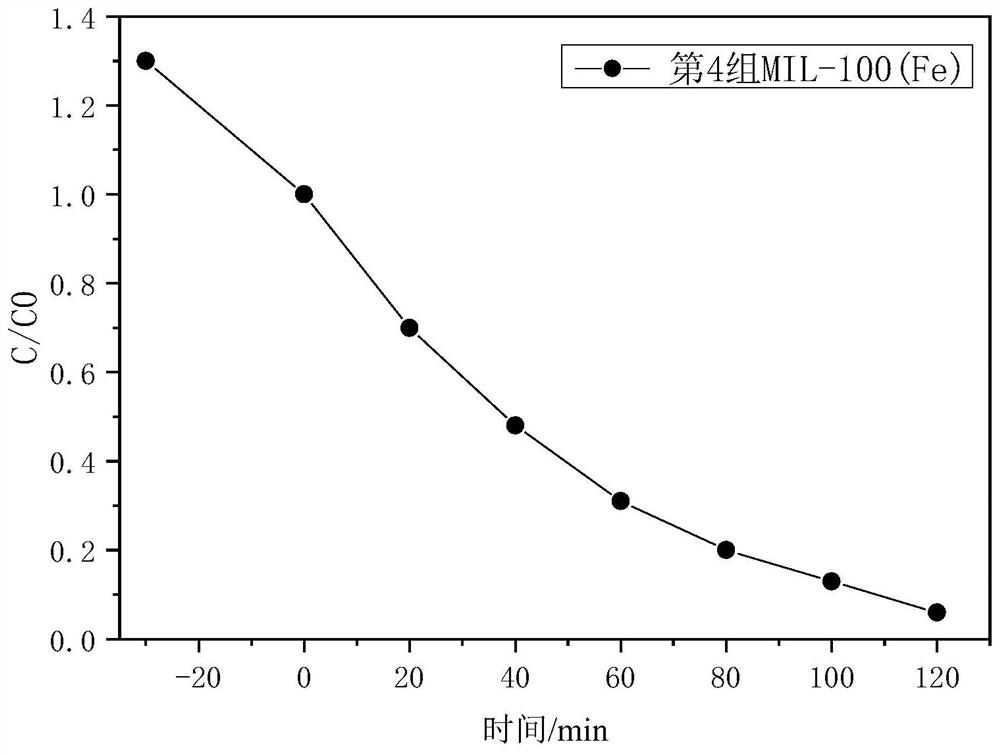

Preparation method of visible light response type MIL-100(Fe) photocatalytic composite material

A composite material and photocatalytic technology, which is applied in the field of preparation of visible light responsive MIL-100 photocatalytic composite materials, can solve problems such as complex preparation process, and achieve the effects of increasing specific surface area, reducing size, and strong adsorption and capture ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

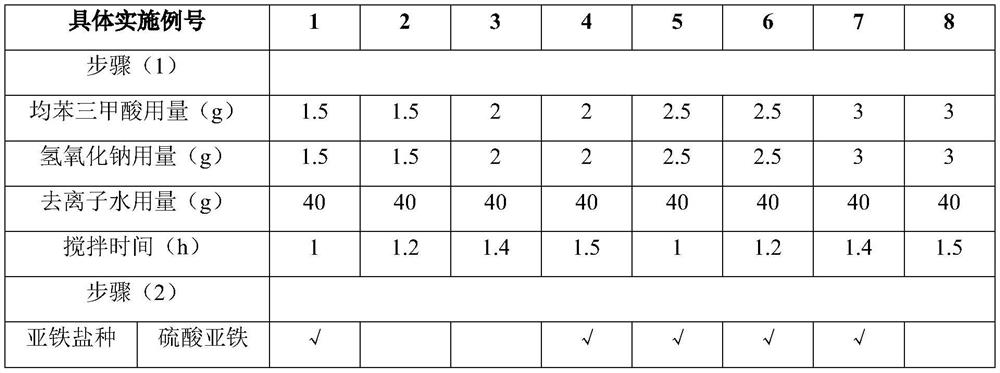

[0025] The present invention will be further described in detail below in conjunction with specific embodiments. The examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

[0026] The preparation method of the visible light response type MIL-100 (Fe) photocatalytic composite material of the present invention comprises the following steps:

[0027] (1) Preparation of trimesic acid / sodium hydroxide composite solution:

[0028] Take 15 to 30 parts by mass of trimesic acid and sodium hydroxide of the same mass, and add them to 400 parts by mass of deionized water; magnetically stir for 1 to 1.5 hours to obtain a uniformly mixed clear and transparent solution;

[0029] (2) prepare ferrous salt solution:

[0030] Dissolve ferrous salt in deionized water at room temperature to prepare a solution with a volume mole fraction of 1mol / L;

[0031] (3) Preparation of visible light-responsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com