Method for preparing fermentation product rich in natural ajoene

A technology for fermented product and ajoene, which is applied in the field of natural fermentation of garlic to prepare ajoene, can solve the problems of using large organic solvents, difficult to realize industrialized production, and low extraction amount of ajoene, and achieves a simple, strong and practical process. Value, cost-saving effect of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method rich in natural ajoene fermented product, which comprises the following steps:

[0030] 1. Get 10Kg of garlic from Shandong, peel it, and grind it to a particle size of 5mm with a pulverizer.

[0031] 2. Put the above-mentioned garlic grains in a grinder, adjust the grinding speed to 20r / min, and the grinding particle size to 0.3mm. Add 10Kg of sesame oil while grinding, and grind into a garlic-vegetable oil mixture.

[0032] 3. Put the above mixture in a fermenter, adjust the temperature to 30°C, and ferment naturally for 8 days, stirring once a day.

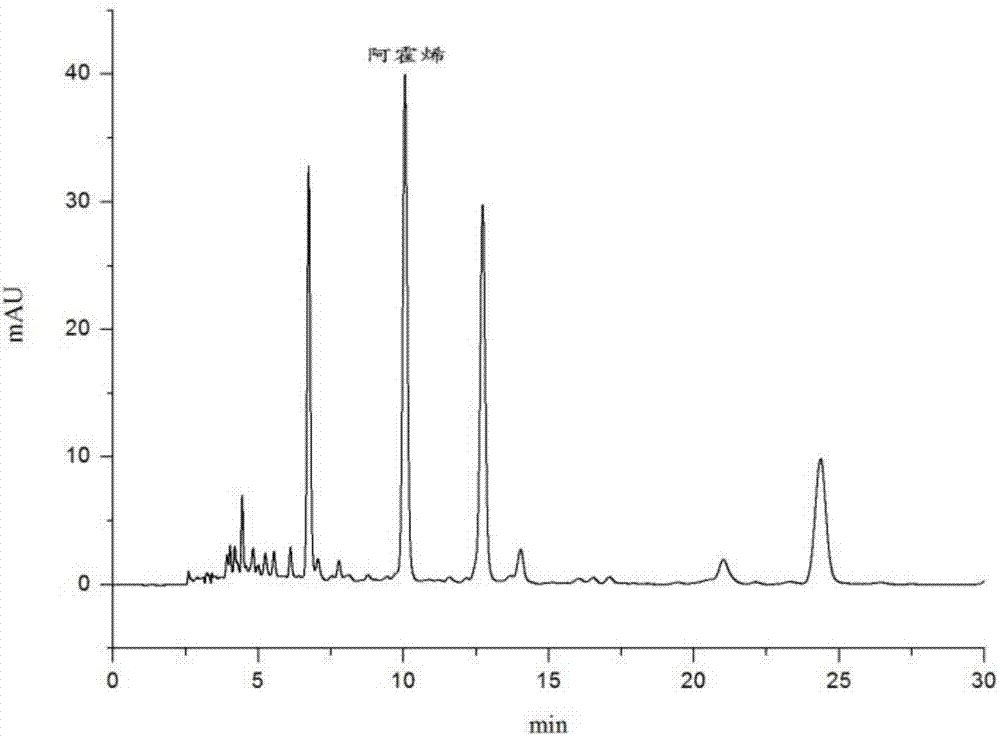

[0033] 4. After the fermentation is completed, the garlic-vegetable oil mixed fermented product is filtered or centrifuged to remove the garlic residue to obtain the garlic-vegetable oil fermented product. Such as figure 1 As shown, the fermented product was detected by high performance liquid chromatography, and the content of ajoene was 0.152%.

Embodiment 2

[0035] A preparation method rich in natural ajoene fermented product, which comprises the following steps:

[0036] 1. Get 10Kg of garlic from Gansu, peel it, and grind it to a particle size of 2mm with a pulverizer.

[0037] 2. Put the above-mentioned garlic grains in a grinder, adjust the grinding speed to 40r / min, and the grinding particle size to 1mm. Add the rapeseed oil of 20Kg while grinding, grind into garlic-vegetable oil mixture.

[0038] 3. Put the above mixture in a fermenter, adjust the temperature to 60°C, and ferment naturally for 3 days, stirring 3 times a day.

[0039] 4. Filter or centrifuge the above-mentioned fermented product to remove garlic residues to obtain a garlic vegetable oil fermented product. The fermented product was detected by high performance liquid chromatography, and the content of ajoene was 0.125%.

Embodiment 3

[0041] A preparation method rich in natural ajoene fermented product, which comprises the following steps:

[0042] 1. Get 20Kg of garlic from Yunnan, peel it, and grind it to a particle size of 10mm with a pulverizer.

[0043] 2. Put the above-mentioned garlic grains in a grinder, adjust the grinding speed to 5r / min, and the grinding particle size to 0.05mm. Add 4Kg of peanut oil while grinding, and grind into garlic-vegetable oil mixture.

[0044] 3. Put the above mixture in a fermenter, adjust the temperature to 10°C, and ferment naturally for 15 days, stirring once every 3 days.

[0045] 4. After 15 days, filter or centrifuge the garlic-vegetable oil fermentation mixture to remove garlic residues to obtain a garlic-vegetable oil fermented product. The fermented product was detected by high performance liquid chromatography, and the content of ajoene was 0.142%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com