Liquid material vaporization apparatus

A technology for liquid materials and gasification devices, which is applied in boiling devices, gaseous chemical plating, metal material coating processes, etc., and can solve the problems of difficulty in stably generating material gas and inability to stably gasify

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

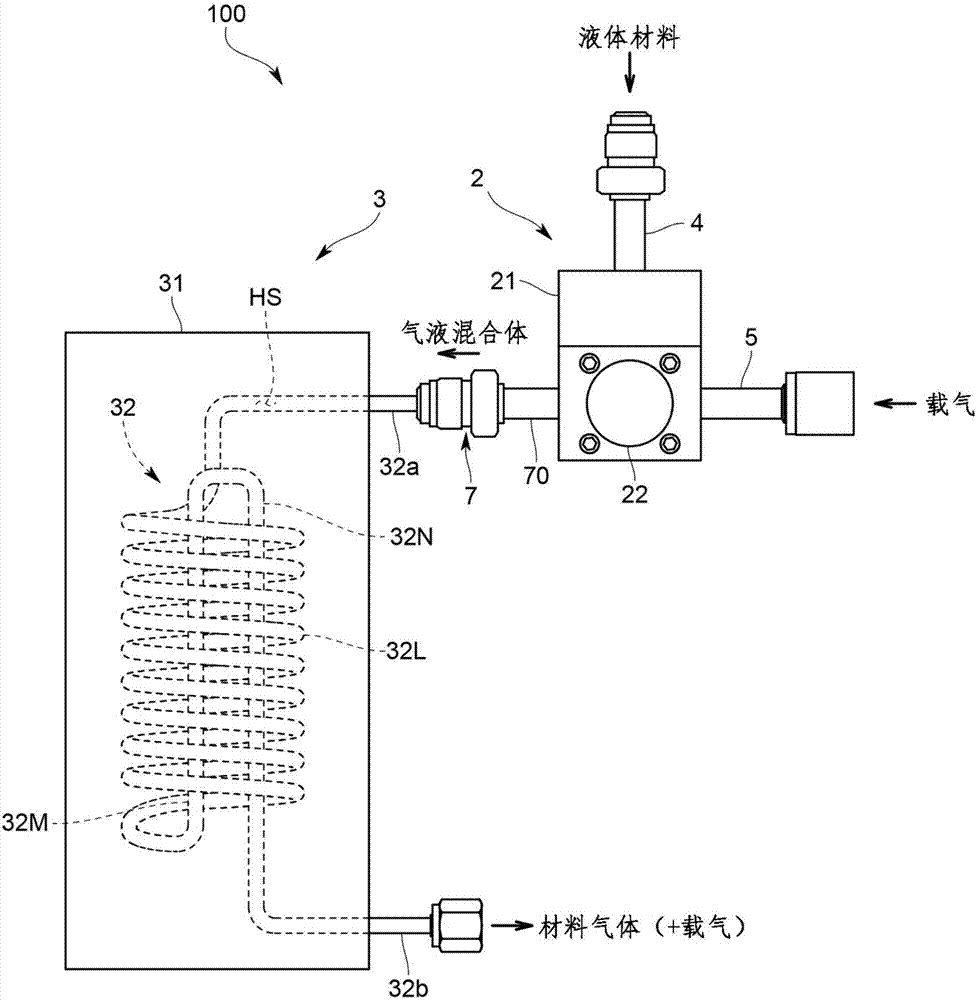

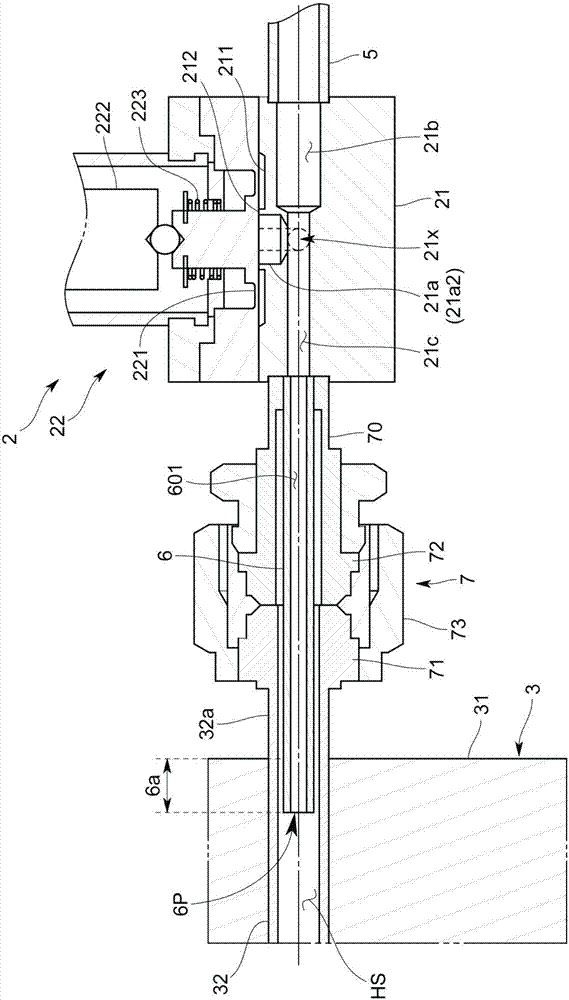

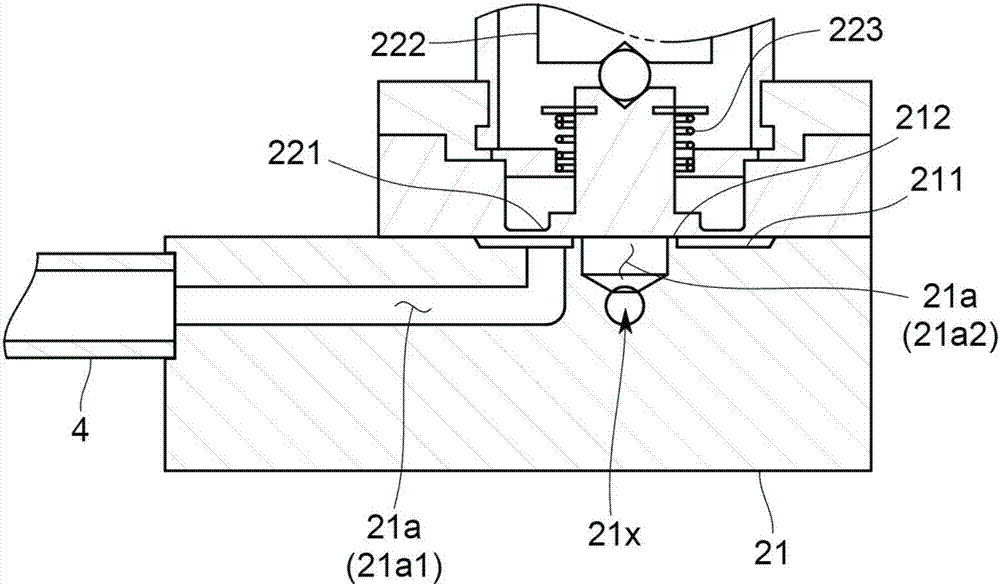

[0034] One embodiment of the liquid material vaporization device of the present invention will be described below with reference to the drawings.

[0035] The liquid material vaporization device 100 of this embodiment is, for example, assembled in an optical fiber manufacturing device and used in an optical fiber manufacturing process. In addition, for example, it can be incorporated into a semiconductor manufacturing device and used in a semiconductor manufacturing process.

[0036] Specifically, as figure 1 As shown, the liquid material vaporization device 100 includes: a gas-liquid mixing part 2, which mixes the liquid material and a carrier gas as a gas to form a gas-liquid mixture; and a gasification part 3, which heats the gas-liquid mixture and utilizes The carrier gas guides out the material gas obtained by vaporizing the liquid material.

[0037] In addition, the liquid material is OMCTS (octamethylcyclotetrasiloxane, boiling point 175° C.), TEOS (tetraethoxysilane,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com