Novel silent chain and tensioning device thereof

A technology of tensioning device and toothed chain, which is applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc. Small friction, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

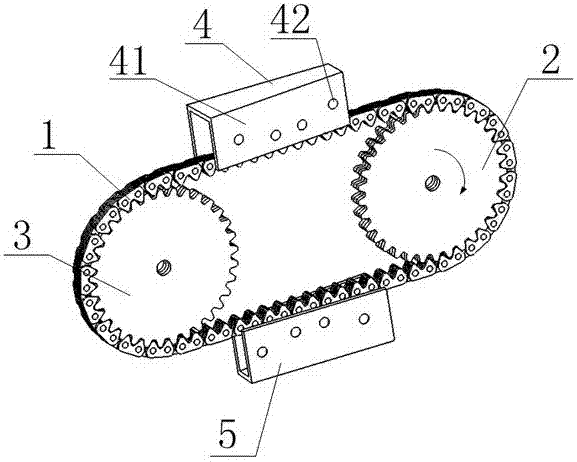

[0027] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the present invention is made up of circular pin toothed chain 1, driving sprocket 2, driven sprocket 3, upper tensioning guide rail device 4 and lower tensioning guide rail device 5, driving sprocket 2 and driven sprocket 3 The structure is the same, the upper tension guide rail device 4 and the lower tension guide rail device 5 have the same structure, the round pin toothed chain 1 is wound on the driving sprocket 2 and the driven sprocket 3, the upper tension guide rail device 4 and the lower tension rail device The guide rail device 5 is respectively arranged at the upper and lower ends of the round pin toothed chain 1;

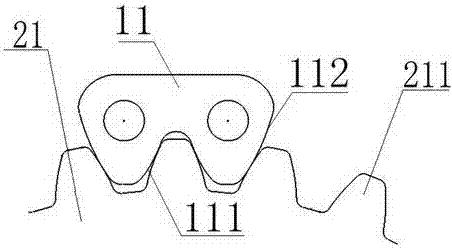

[0028] Described driving sprocket 2 comprises sprocket 21, has several sprocket teeth 211 on the sprocket 21, and sprocket tooth 211 is an involute tooth profile;

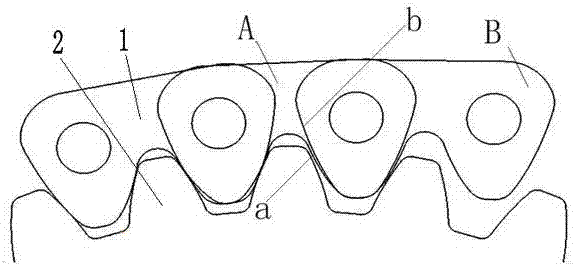

[0029] The round pin toothed chain 1 has several chain plates 11, the inner convex tooth profil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com