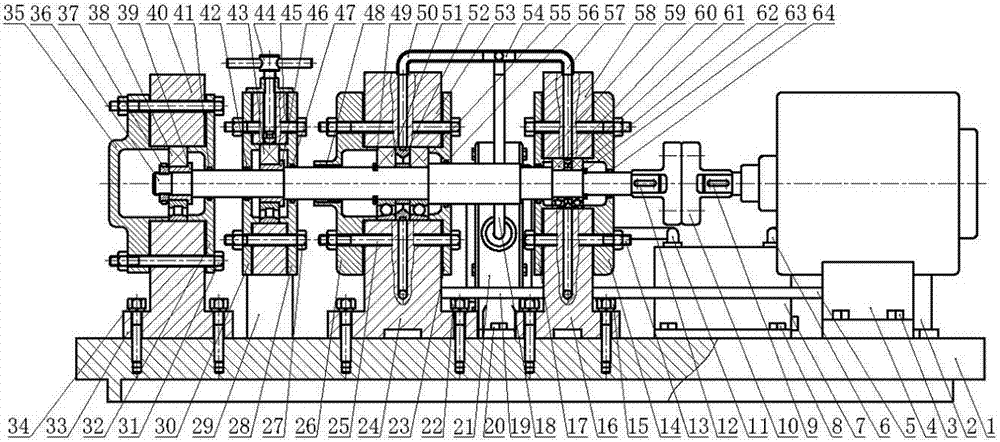

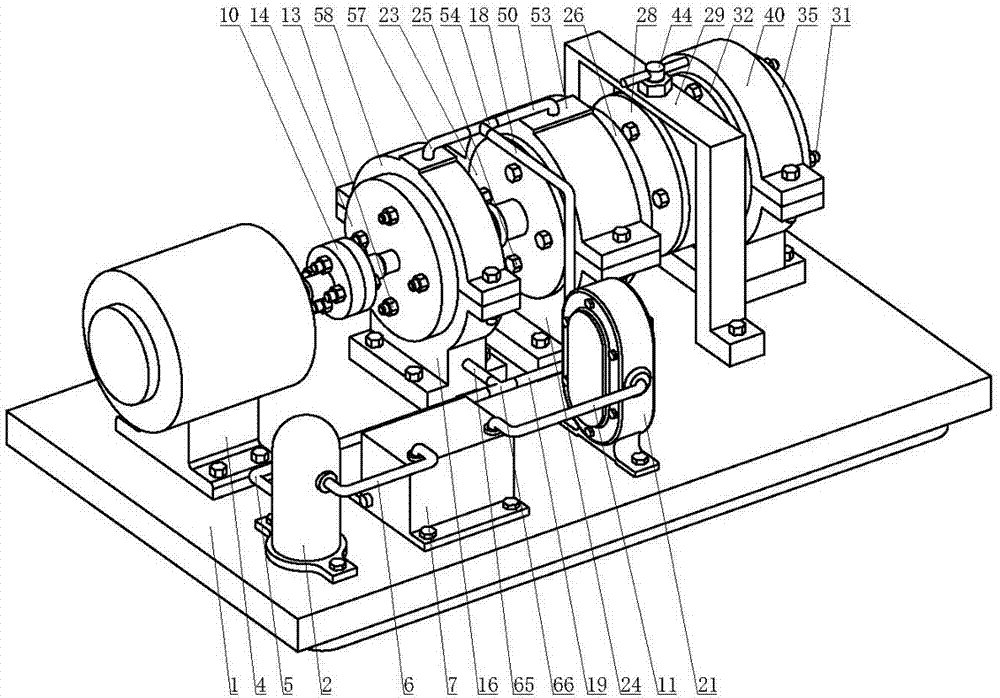

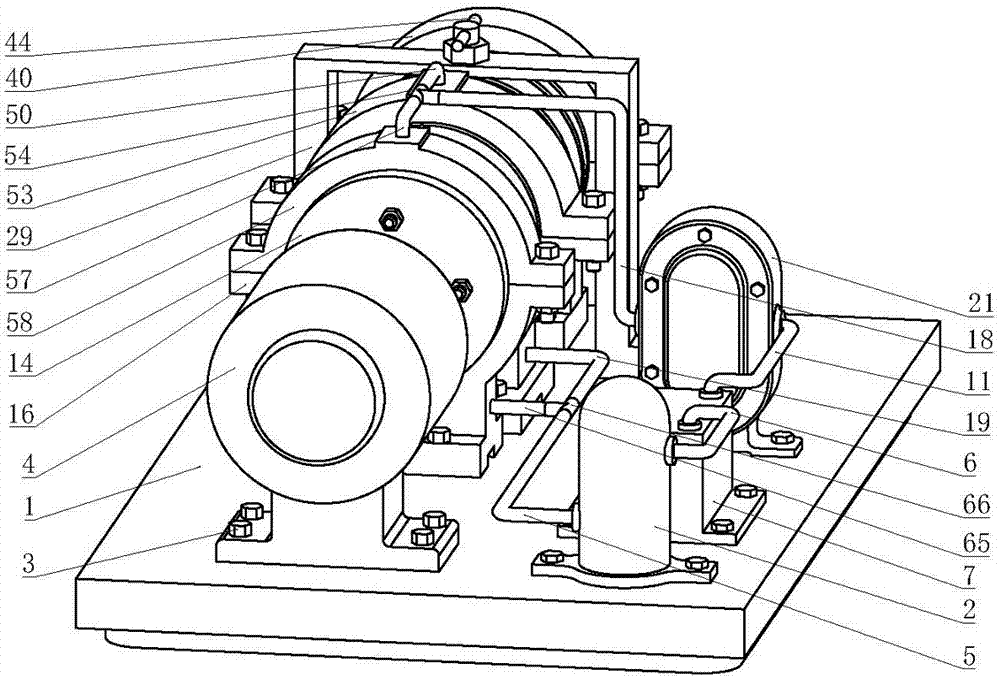

Forced oil lubricated high-speed rolling bearing test bench

A high-speed rolling and bearing test technology, which is applied in the direction of mechanical bearing testing, etc., can solve the problems of decreased lubrication performance and limited operating speed, and achieve the effects of preventing inaccurate detection, realizing cooling and recycling, and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0014] as attached figure 1 , attached figure 2 And attached image 3 As shown, the present invention includes base 1, filter 2, fastening bolt I3, motor 4, oil pipe I5, oil pipe II6, oil tank 7, fastening bolt II8, flat key I9, coupling 10, oil pipe III11, flat key II12 , fastening bolt Ⅲ13, bearing end cover Ⅰ14, fastening bolt Ⅳ15, bearing seat lower part Ⅰ16, bearing end cover Ⅱ17, oil pipe Ⅳ18, oil pipe Ⅴ19, fastening bolt Ⅴ20, oil pump 21, fastening bolt Ⅵ22, bearing end cover Ⅲ23, Lower part of bearing seat Ⅱ24, fastening bolt Ⅶ25, bearing end cover Ⅳ26, fastening bolt Ⅷ27, loading bearing end cover Ⅰ28, bracket 29, loading bearing end cover Ⅱ30, fastening bolt Ⅸ31, test bearing end cover Ⅰ32, test bearing seat lower part 33, fastening bolt X34, test bearing end cover II35, rotating shaft 36, round nut 37, test bearing 38, positioning sleeve I39, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com