Alternating current sensor based on magnetoelectric laminate material and with C-type magnetic ring

A technology of alternating current and laminated materials, applied in the direction of AC/pulse peak measurement, measuring device magnet, frequency measuring device, etc., can solve the problems of power failure threading, passing through the heart, unfavorable installation and maintenance, etc., and improve the measurement sensitivity , Easy to install and maintain, good anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail as follows:

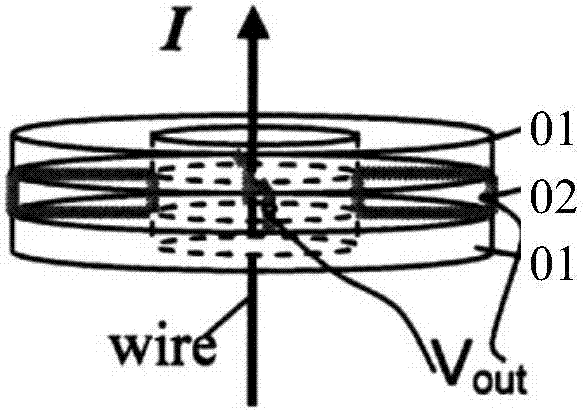

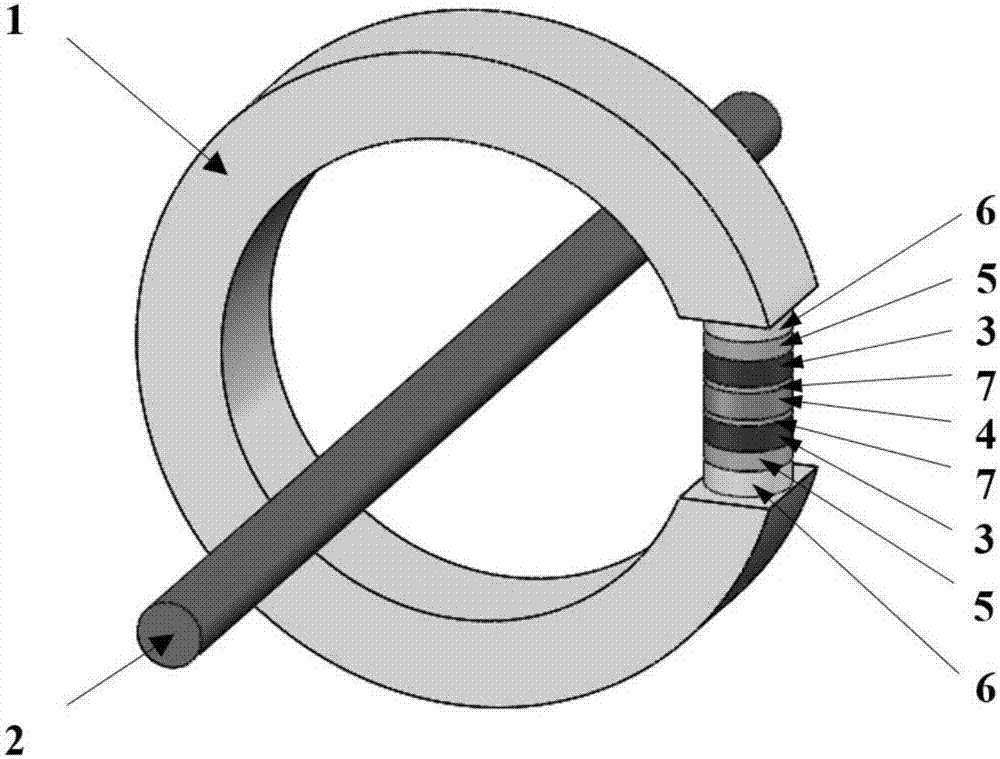

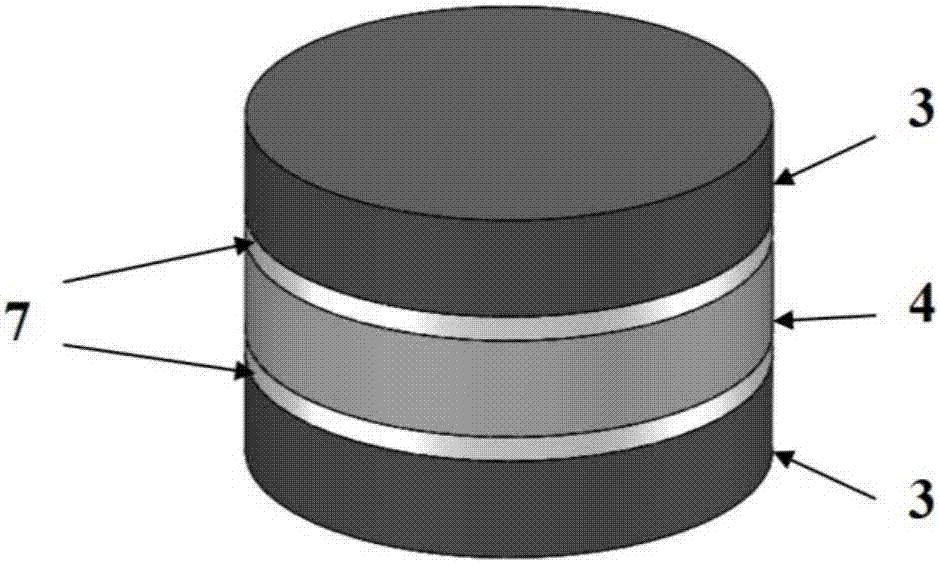

[0022] The present invention proposes an AC current sensor based on a magnetoelectric laminated material with a C-shaped magnetic ring. The overall structure is as follows: figure 2 As shown, the AC current sensor is a closed ring structure composed of a C-shaped magnetic ring 1 and a measurement module located at the gap of the C-shaped magnetic ring (the gap is the air gap of the C-shaped magnetic ring). A detachable connection is formed between the ring 1 and the measurement module through the supporting layer 6; wherein, the measurement module is a layered structure, including a magnetoelectric laminated material in the middle, and permanent magnets arranged symmetrically along the thickness direction of the magnetoelectric laminated material Layer 5, the cross section of the C-shaped magnetic ring 1 and the permanent magnet laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com