Automatic wafer conveying machine and method

A wafer, automatic technology, applied in the manufacture of conveyor objects, electrical components, semiconductor/solid-state devices, etc., can solve problems such as wafer breakage and damage, and achieve the effect of convenient handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

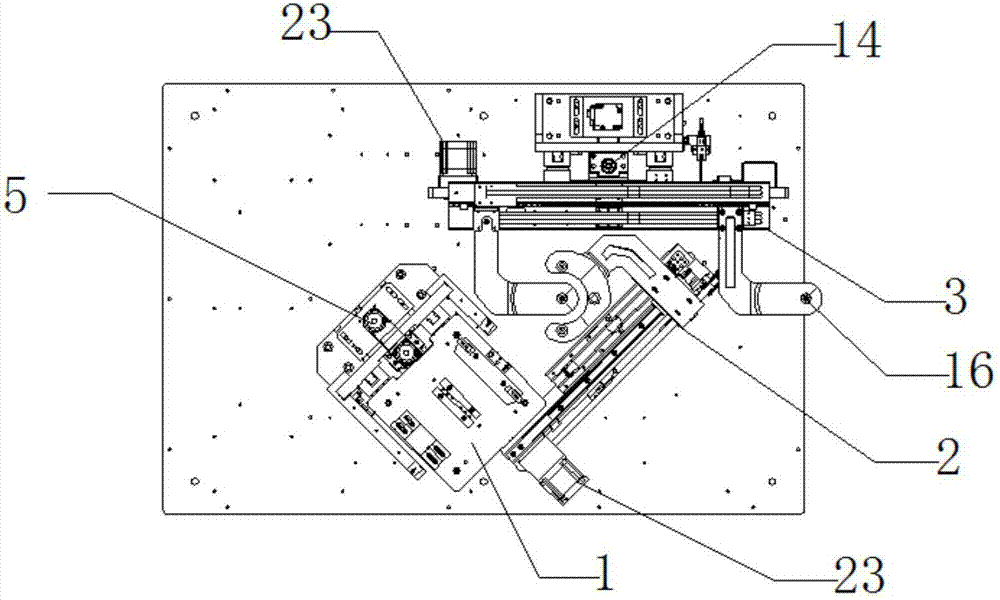

[0045] refer to Figure 1 to Figure 10 , an automatic wafer transfer machine, the automatic wafer transfer machine includes a cassette module 1, a first robot arm module 2 for extracting and storing wafers, and a wafer on the first robot arm module for transferring To the second mechanical arm module 3 of the workbench, wherein:

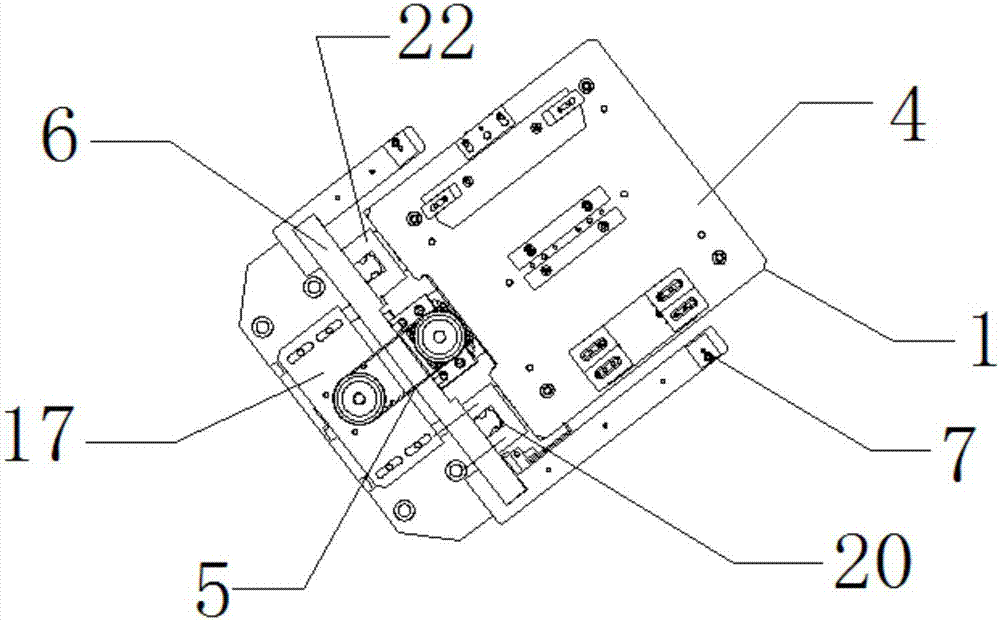

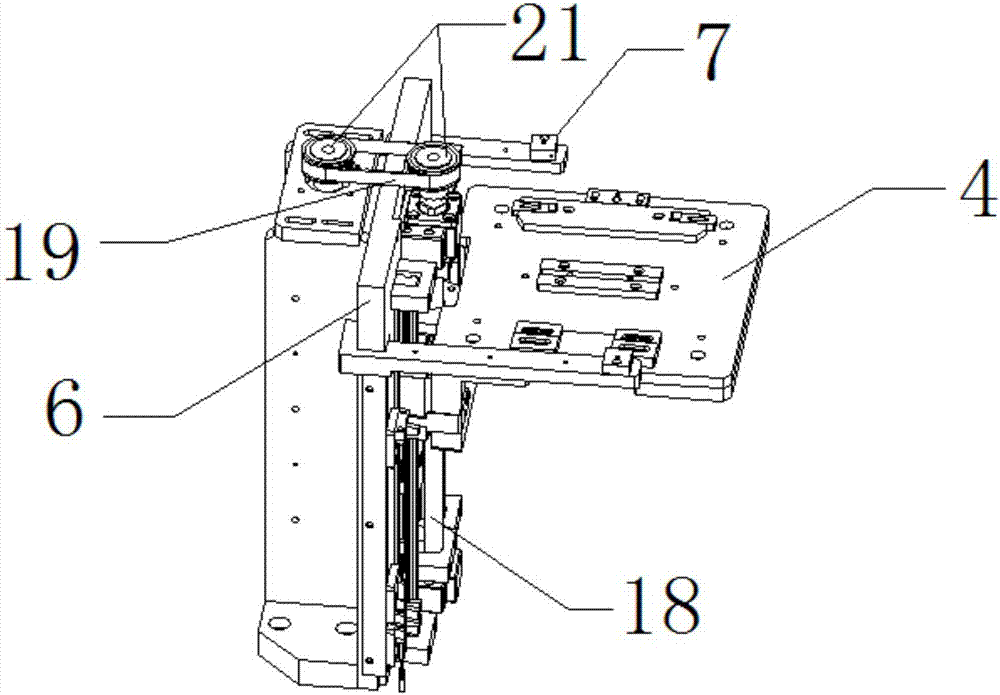

[0046] The cassette module includes a working platform 4 for installing the cassette, a cassette lifting table transmission device 5 for lifting and lowering in the Z-axis direction, and a cassette module fixing frame 6. Optical fiber sensors 7 on both sides of the platform for scanning wafers in the cassette;

[0047] The first mechanical arm module includes a first mechanical arm fixing base 8 provided with a linear slide rail 27, a linear transmission device 9 on one side of the first mechanical arm fixing base, and a first mechanical arm 10 reciprocating on the linear sliding rail. , the end of the first robotic arm is provided with a "C"-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com