A kind of rifapentine capsule and preparation method thereof

A technology for rifapentine and capsules, which is applied in the field of rifapentine capsules and their preparation, can solve the problems of large differences in the loading of rifapentine capsules and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031]The preparation method of rifapentin capsules provided by the present invention is to use fluidized bed granulation method to produce rifapentin capsules, and combine Tween 80, HPMC and K12Add pure ethanol to dissolve into a binder, use the binder to spray rifapentin raw materials to prepare rifapentin granules; then add HPMC, BHA and vitamin C into pure ethanol to dissolve into a coating liquid, and Use the coating solution to spray-coat the rifapentin granules to prepare rifapentin coated granules; finally, mix the rifapentin coated granules with pregelatinized starch for total mixing. Fill it to prepare rifapentin capsules. It solves the problem of large difference in rifapentin capsules caused by direct mixing and granulation of the original powder, and at the same time, the dissolution rate and the quality of related substances are also improved.

[0032]The amounts and sources of the raw and auxiliary materials used in the embodiments of the present invention are shown in T...

Embodiment 1

[0037]Example 1 Preparation of Rifapentin Capsules

[0038](1) Prescription of raw materials and excipients (per 10,000 tablets)

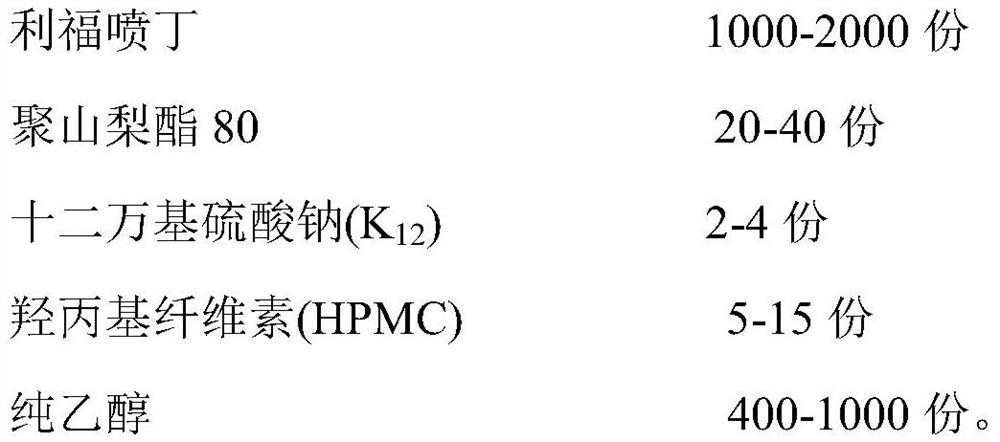

[0039]Based on parts by weight, rifapentin granules are formulated with the following components:

[0040]

[0041]Based on parts by weight, rifapentin coated granules are prepared from the following components:

[0042]

[0043](2) Specific preparation process

[0044]1) Add Tween 80, HPMC and K12 to pure ethanol to dissolve into a binder, pass through a 100-mesh sieve, and set aside;

[0045]2) Put the prescription amount of rifapentin in the granulating coating pan. When the temperature of the material in the granulating coating pan reaches 35℃, the top spray granulation will be started. The temperature of the material will be controlled at 40℃ during the whole granulation process. Until all the spraying is finished, the material is passed through a 20-mesh screen, and particles larger than 20-mesh are removed to obtain rifapentin particles;

[0046]3) Add HPMC, BHA and vitamin...

Embodiment 2

[0049]Example 2 Preparation of Rifapentin Capsules

[0050](1) Prescription of raw materials and excipients (per 10,000 tablets)

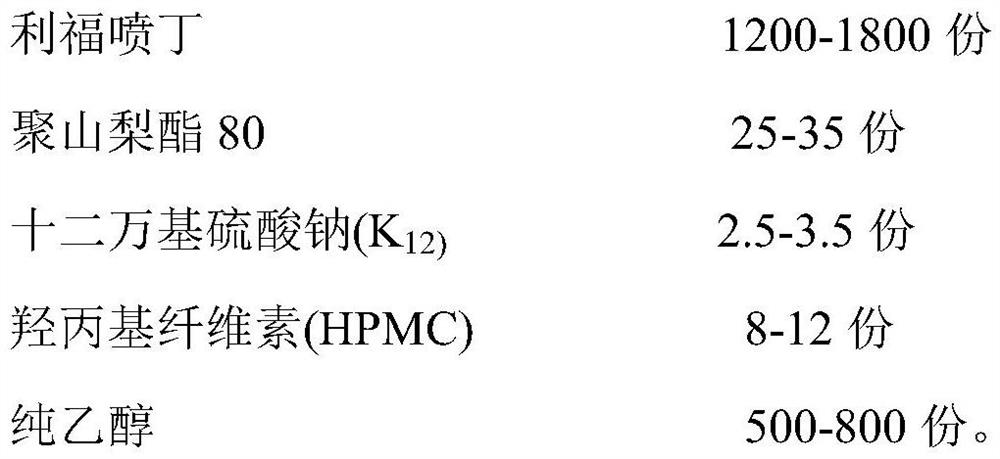

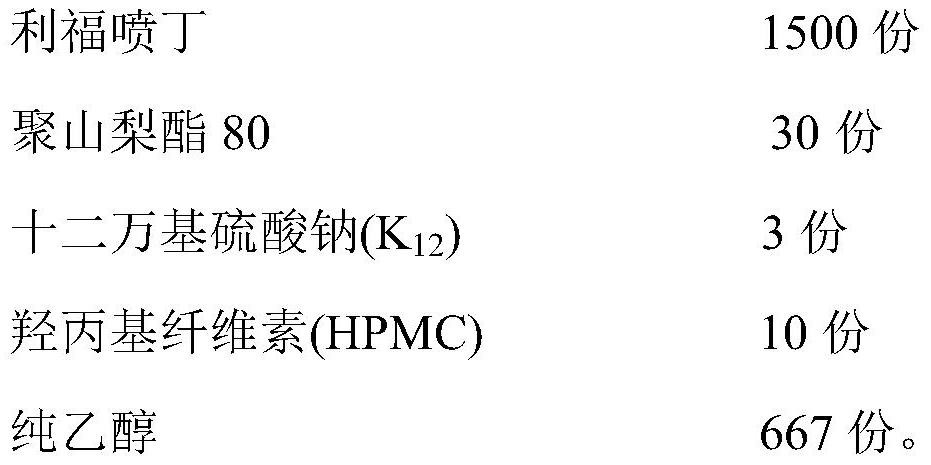

[0051]Based on parts by weight, rifapentin granules are formulated with the following components:

[0052]

[0053]Based on parts by weight, rifapentin coated granules are prepared from the following components:

[0054]

[0055](2) Specific preparation process

[0056]1) Add Tween 80, HPMC and K12 to pure ethanol to dissolve into a binder, pass through a 100-mesh sieve, and set aside;

[0057]2) Put the prescription amount of rifapentin in the granulating coating pan. When the temperature of the material in the granulating coating pan reaches 35℃, the top spray granulation will start, and the temperature of the material will be controlled at 30-35 during the whole granulation process. ℃, until all spraying is finished, the material is passed through a 20-mesh screen, and particles larger than 20-mesh are removed to obtain rifapentin particles;

[0058]3) Add HPMC, BHA and vitamin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com