Low-stress fixture for cutting test on metal test piece

A cutting test and metal test piece technology, applied in metal processing machinery parts, workpiece clamping devices, metal processing equipment, etc. Small deformation and the effect of reducing residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

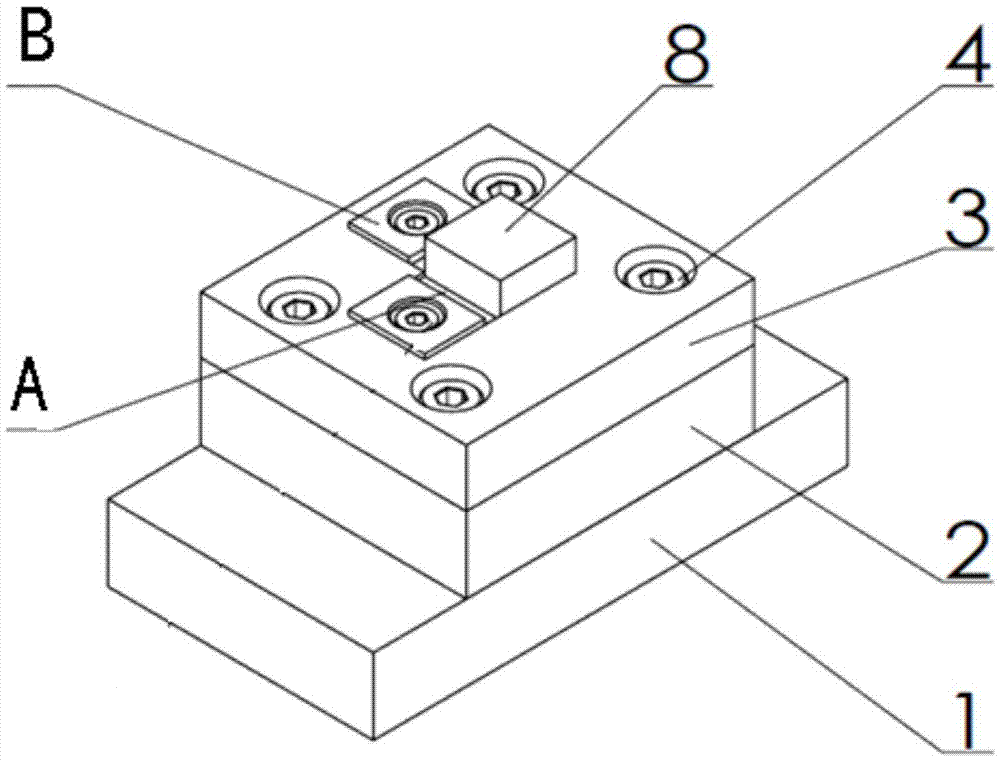

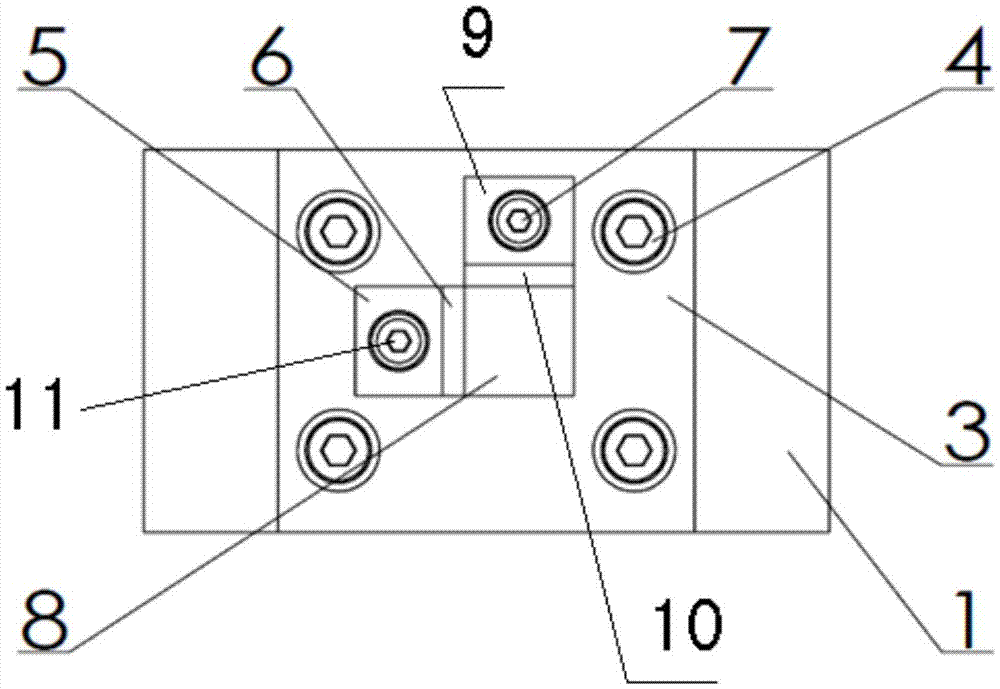

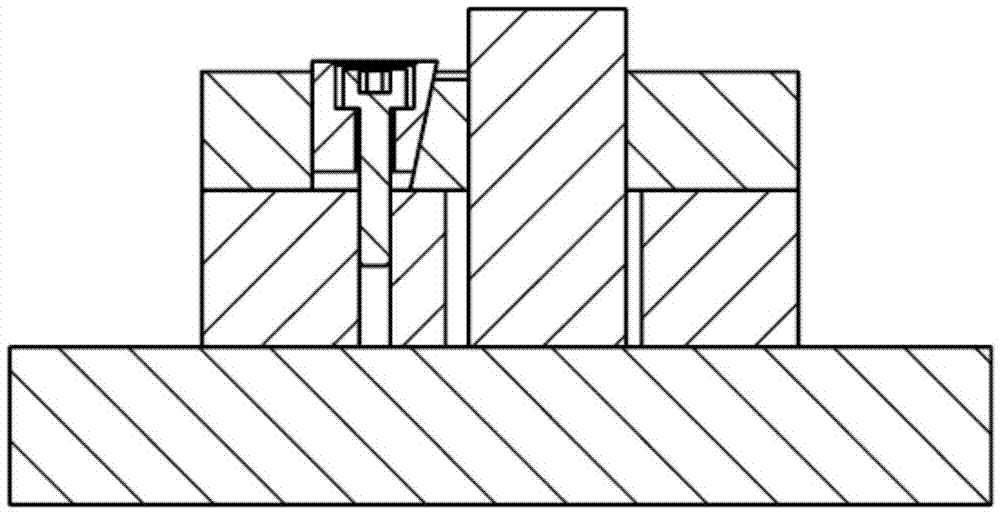

[0023] The specific embodiment of the present invention will be further described in conjunction with accompanying drawing:

[0024] A low-stress fixture for cutting tests on metal specimens, characterized in that,

[0025] Including the lower base 1, the middle base 2, the upper base 3, the upper base 3 has an L-shaped through hole, the middle base 2 has a through square mounting hole, the square test piece 8 passes through the L-shaped through hole and the square mounting hole in turn, The bottom surface of the square test piece 8 is pressed on the upper surface of the lower base 1,

[0026] It also includes a first clamping block A and a second clamping block B, the first clamping block A and the second clamping block B are vertically arranged in the L-shaped through hole, and the square test piece 8 passes through the first reference plane perpendicular to each other Positioning with the second reference plane, the first clamping block A presses against the opposite surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com