Ultralong rod polytrifluorochloroethylene manufacturing method

A technology of polychlorotrifluoroethylene and its production method, which is applied in the field of producing system devices and ultra-long rods of polychlorotrifluoroethylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

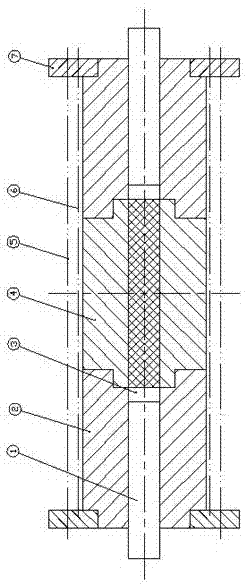

[0023] Accompanying drawing has provided an embodiment of the present invention, can find out by accompanying drawing, the present invention relates to a kind of ultra-long bar polytrifluorochloroethylene manufacture method, adopts vertical compression molding method, a vertical compression molding equipment is set type compression molding die, the core part of the vertical compression molding die is attached figure 1 As shown, the core part of the abrasive tool includes the upper and lower pressure rods 1, the upper and lower material chambers 2, the upper and lower sliders 3, the plastic cavity 4, the locking bolts 5, the heater 6, and the upper and lower pressure rings 7; There is an upper and lower slider 3, and by controlling the minimum height of the upper and lower slider 3 and the polychlorotrifluoroethylene bar for molding, the height of the super-long material is ensured; then the molding raw material is selected, the parameters of the molding equipment are controlled...

Embodiment 2

[0042] The basic principle of embodiment two is the same as embodiment one, but the raw materials that adopt and process parameter are slightly different;

[0043] The raw material is Daikin material, choose M-300H, M-300P or M-300 powder; M-300 is powdery, with an apparent density of 0.6; M-300H is granular powder, with an apparent density of 0.95; M-300P For particles, the apparent density is 1.10. After repeated tests, the best model ranking suitable for vertical compression molding is: M-300H is better than M-300P is better than M-300.

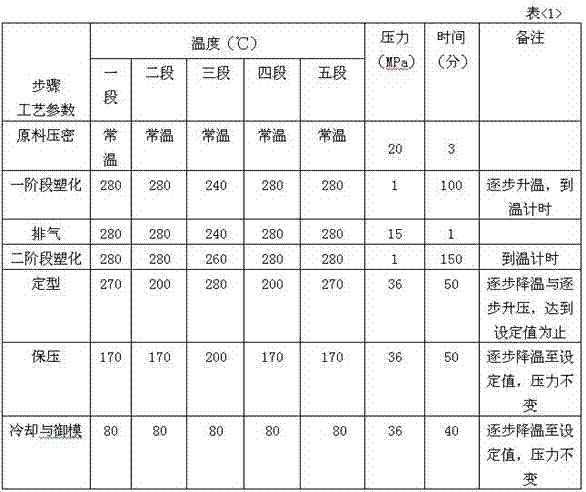

[0044] Determination of plasticizing process temperature:

[0045] According to the material characteristics of polytrifluorochloroethylene, its melting point is 210-212°C. Through experiments, when the temperature reaches 340°C, the material will decompose. Therefore, the molding plasticizing temperature range should be higher than the melting point of 212°C and lower than the decomposition temperature of 340°C.

[0046] Determination ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com