Automatic box type packaging machine integrated cutting device

An automatic box type and cutting device technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of long main body occupying production space, high production cost, complicated production, etc., achieve simple structure, reduce equipment cost, increase The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

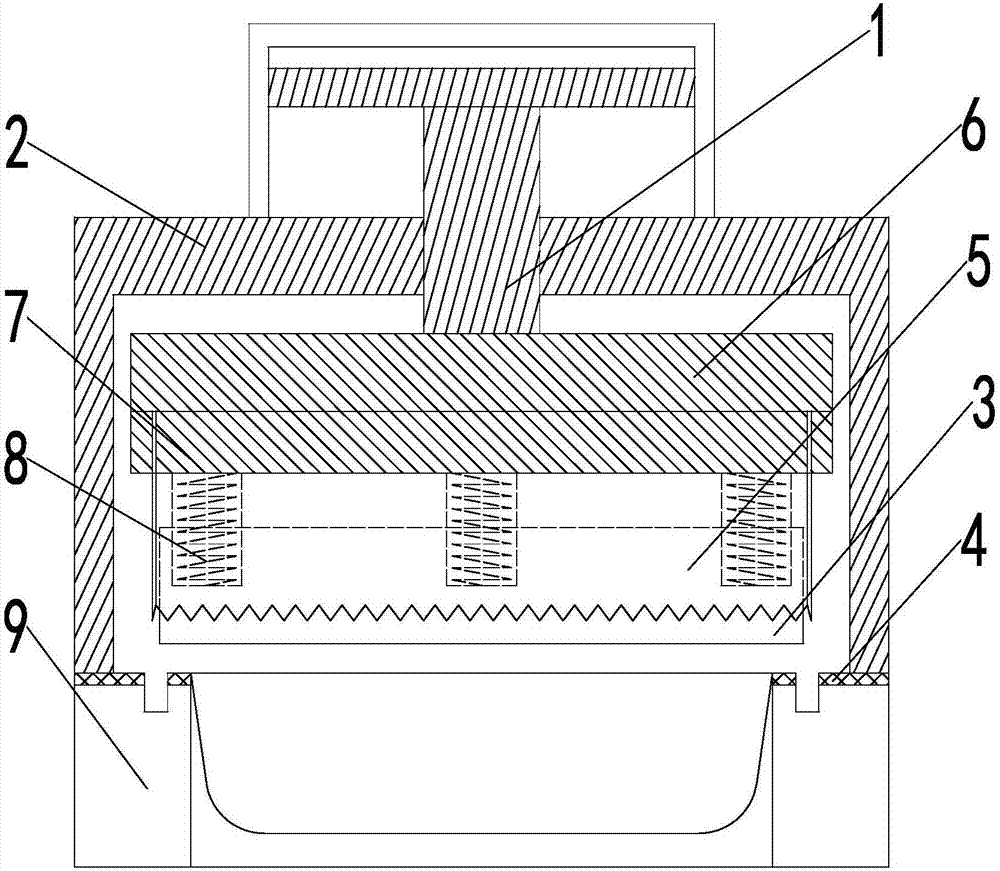

[0008] Such as figure 1 As shown, the present invention includes a cylinder 1, a mounting plate 2, a sealing heating strip 3, a sealing silica gel strip 4 and a cutter, and is characterized in that the bottom end of the cylinder 1 runs through the mounting plate 2 and is connected with the cylinder pressure plate 6. The bottom of cylinder pressure plate 6 is connected with cutter fixed plate 7, and the sidewall of described cutter fixed plate 7 is fixed with cutter 5, and the bottom of described cutter fixed plate 7 is connected with sealing heating bar 3 by stage clip 8, The lower edge of the sealing heating strip 3 is lower than the lower edge of the cutter 5, and the sealing heating strip 3 corresponds to the sealing silica gel strip 4 arranged on the upper end of the product mold.

[0009] Through the above settings, when the present invention is in use, after the packaged product enters the working room, the upper and lower working rooms are tightly closed. After the vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com