Opening-closing pier passing box girder overhaul construction trolley and working method thereof

A construction trolley, opening and closing technology, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of construction difficulty, hidden safety hazards, many procedures, and troublesome construction, so as to shorten the construction period, ensure safety, and improve construction. Good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

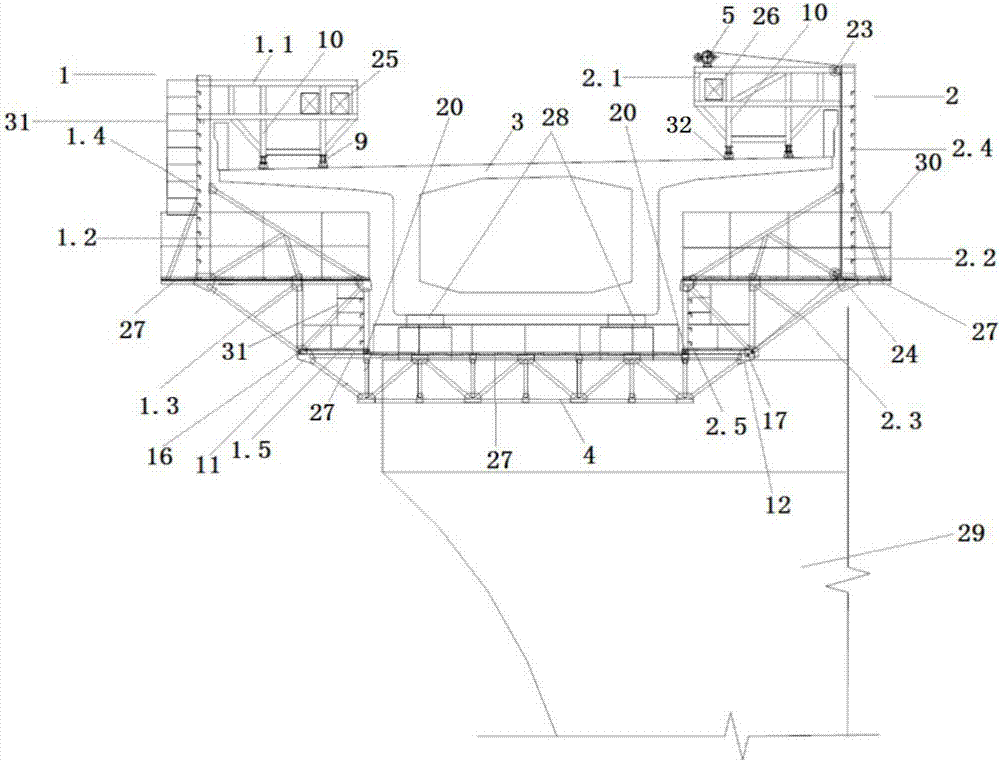

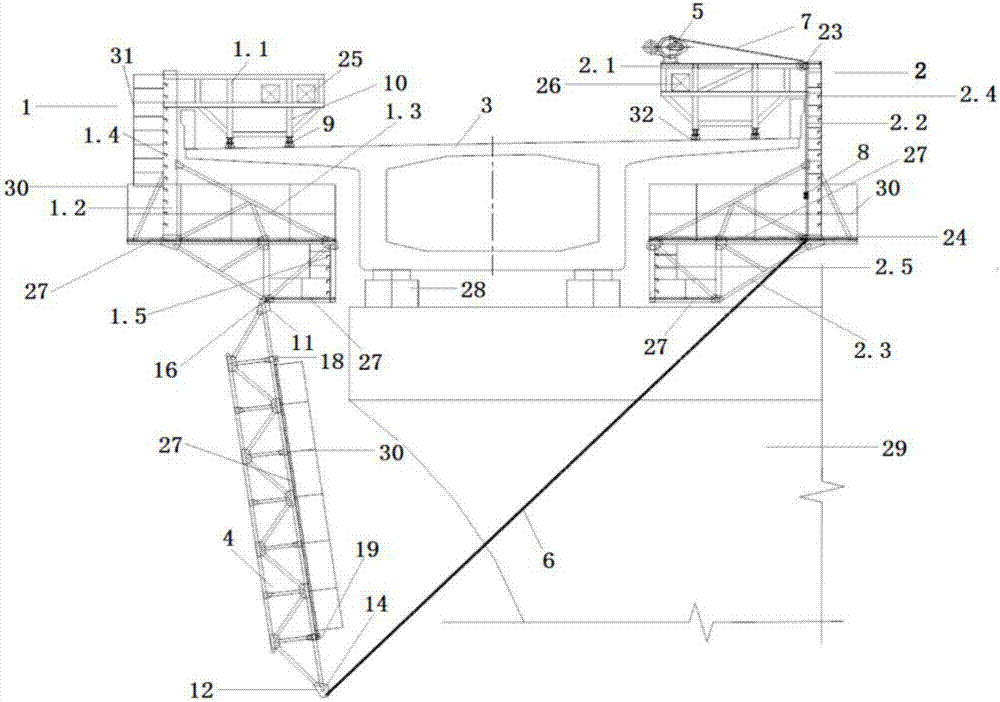

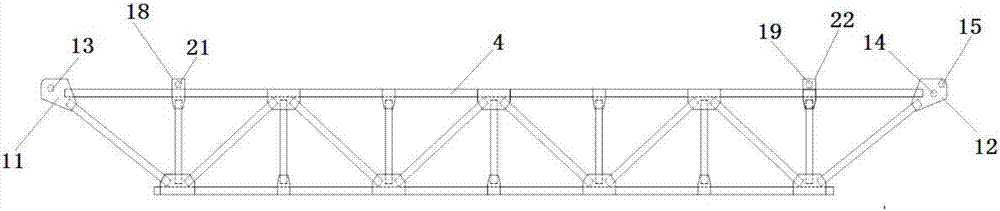

[0024] Such as figure 1 The opening and closing box girder overhauling construction trolley shown in —4 includes the trolley truss erected on both sides of the box girder 3, and the trolley truss includes the first truss 1 erected on the outside of the box girder 3 and the first truss erected on the box girder 3. The second truss 2 on the inner side (the side away from the central axis of the pier 29 is called the outer side in the present invention, and the side near the central axis of the pier 29 is called the inner side in the present invention, the same below), the bottom of the first truss 1 A bottom truss 4 is connected to the bottom of the second truss 2, the outer end of the bottom truss 4 is hingedly connected with the bottom of the first truss 1, the inner end of the bottom truss 4 is fixed with the bottom of the second tru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com