High precision V-shaped mixed manufacturing unit and manufacturing method thereof

A manufacturing unit and high-precision technology, applied in the direction of mixers, manufacturing tools, chemical instruments and methods, etc., can solve the problems of large matching gap between the mixing unit and the outer wall, insufficient mixing, insufficient reaction, etc., to improve the use efficiency of materials , good overall stability and good mixing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings. This embodiment is only used to explain the present invention, and does not constitute a limitation to the protection scope of the present invention.

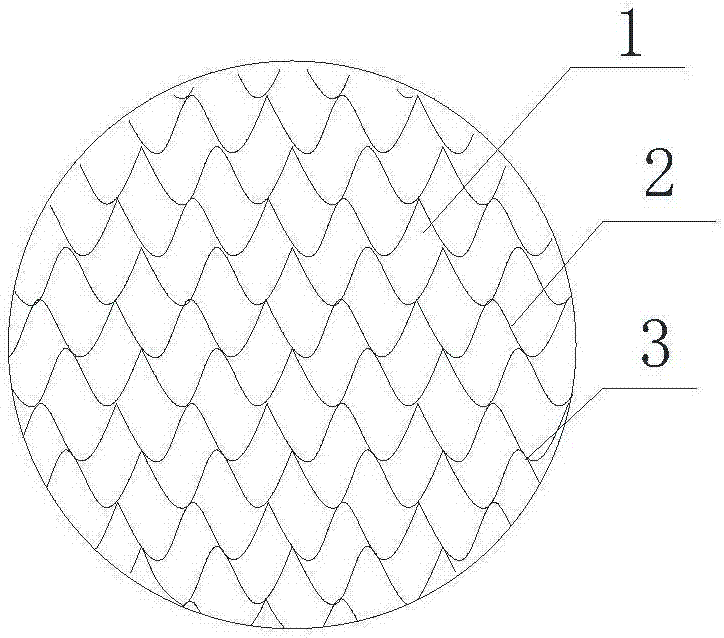

[0017] Such as Figure 1-Figure 3 It shows an embodiment of a high-precision V-shaped hybrid manufacturing unit of the present invention, including a unit main body 1, which is a cylindrical structure, and the unit main body 1 is composed of several corrugated plates 2, and the front and back of the corrugated plates 2 are in sequence Placed superimposed, and a spot welding zone 3 is provided at the contact between every two corrugated plates 2, the corrugated plates 2 are welded and fixed by the spot welding zone 3, the corrugated plate 2 is composed of corrugated units 4, and the corrugated plates 2 on each The corrugated units 4 are parallel to each other, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com