Reactor equipment, reaction system evaluation equipment with reactor equipment and evaluation method

A reaction system and reactor technology, used in chemical instruments and methods, testing food, material inspection products, etc., can solve the problems of high cost, short service life, and insufficient reaction rate, and reduce the difference in logistics flow and reaction conditions. consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0137] In the preparation method of a product described in the present invention, the pressure (absolute pressure) in the reaction process is 0.5-3 bar.

[0138] In the preparation method of a product described in the present invention, the product is an oil product, more preferably a transesterified oil. In a specific embodiment of the present invention, the product prepared by the method of the present invention is 1,3-disaturated fatty acid-2-unsaturated fatty acid glyceride.

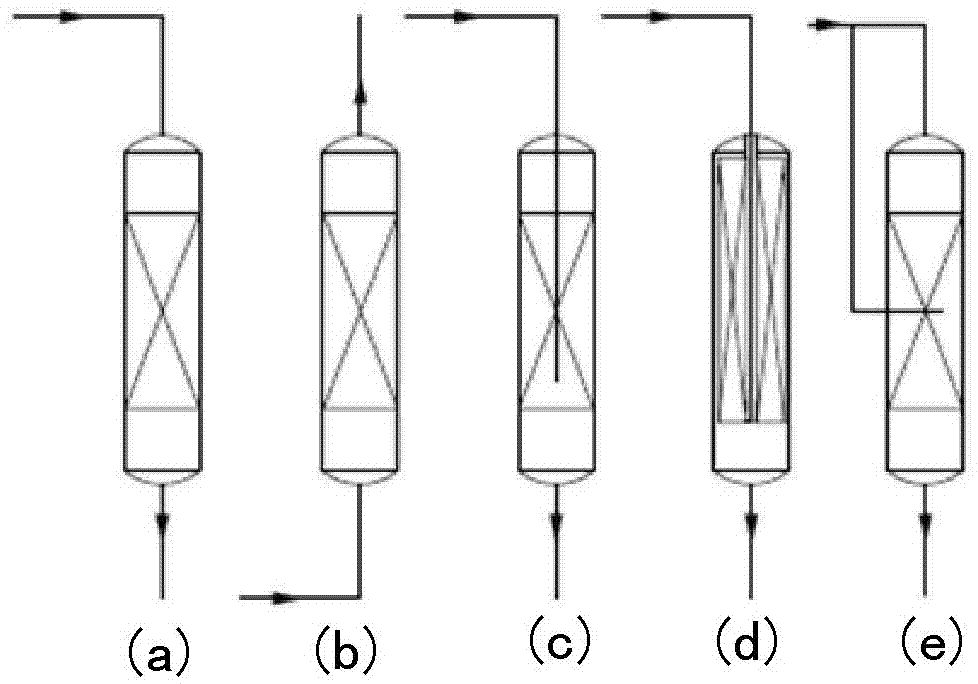

[0139] For the reactor facility in the evaluation method of the reaction system of the present invention, each element described in the above [reactor facility] can be used.

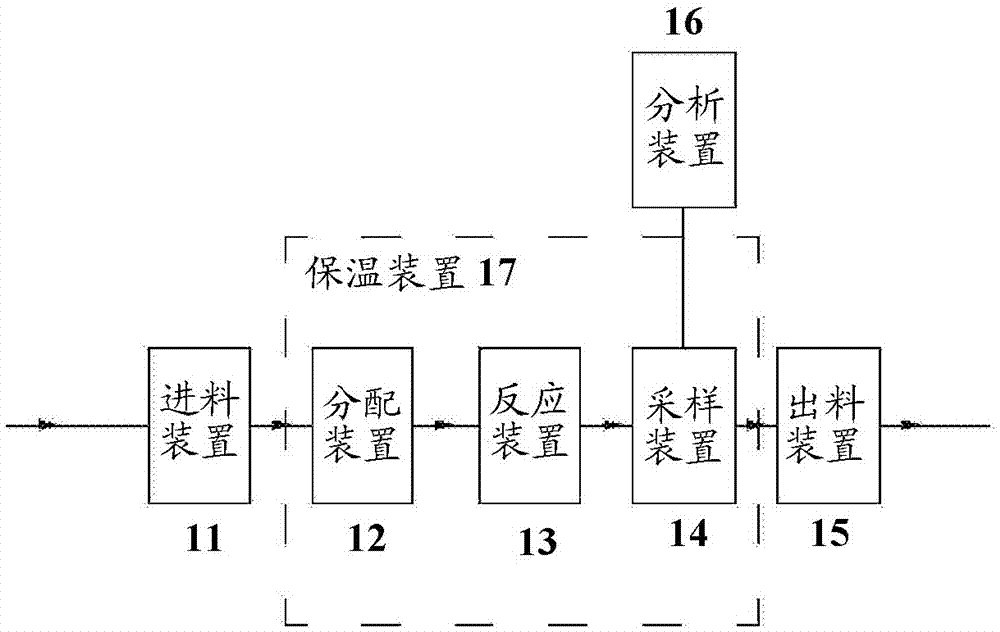

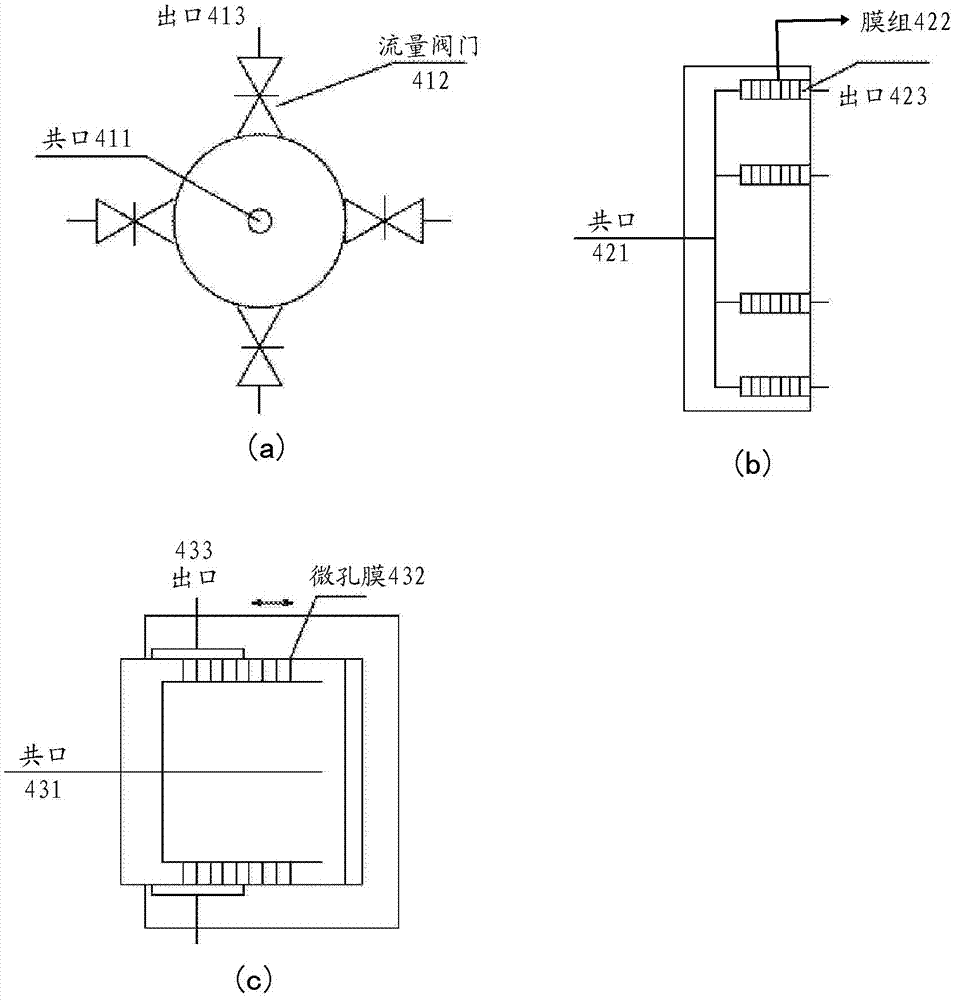

[0140] By using the above-mentioned reactor equipment of the present invention in the evaluation method of the reaction system of the present invention, in the flow path from each flow path distribution unit to the reactor unit, the flow rate of the stream is mainly determined by the pressure drop of the distribution device Do...

Embodiment 1

[0163] Soak 100g of macroporous adsorption resin X-5 in deionized water overnight, then soak it in 95% ethanol overnight, and finally rinse it several times with deionized water. Add 100 mL of Lipozyme TL100L liquid enzyme and 4 mL of 1% glutaraldehyde solution to the treated resin, and immobilize it in a shaker at 150 rpm at 25 °C for 2 hours. The supernatant was removed by filtration, and the immobilized resin was dried at room temperature to obtain immobilized enzyme X-5.

Embodiment 2

[0165] Weigh 80g of immobilized enzyme X-5 and fill it into reaction column 1, and fill 80g of Lipozyme TL IM into reaction column 2 and reaction column 3 respectively. The feedstock used to test lipase transesterification lifetime was 60% palm stearin (IV 16) and 40% high oleic sunflower oil. A schematic diagram of the equipment used is attached Figure 5shown. The temperature of the oven is set at 65°C, the flow rate of the single tube is controlled at 100g / h, the pressure drop of palm stearin through the distribution device is 10 bar, and the pressure drop through the reaction column is 0.5 bar. The transesterification rate was calculated by measuring the solid fat content of the product at 40°C. Calculated as follows:

[0166] Transesterification rate=(solid fat content of raw material-solid fat content of sample) / (solid fat content of raw material-equilibrium solid fat content)*100%

[0167] The equilibrium solid fat content is the solid fat content of raw materials a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com