Vector tension device and vector tension control method for vertical take-off and landing unmanned aerial vehicle

A tension device and vertical take-off and landing technology, which is applied in the direction of vertical take-off and landing aircraft, power device on the aircraft, power device arrangement/installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

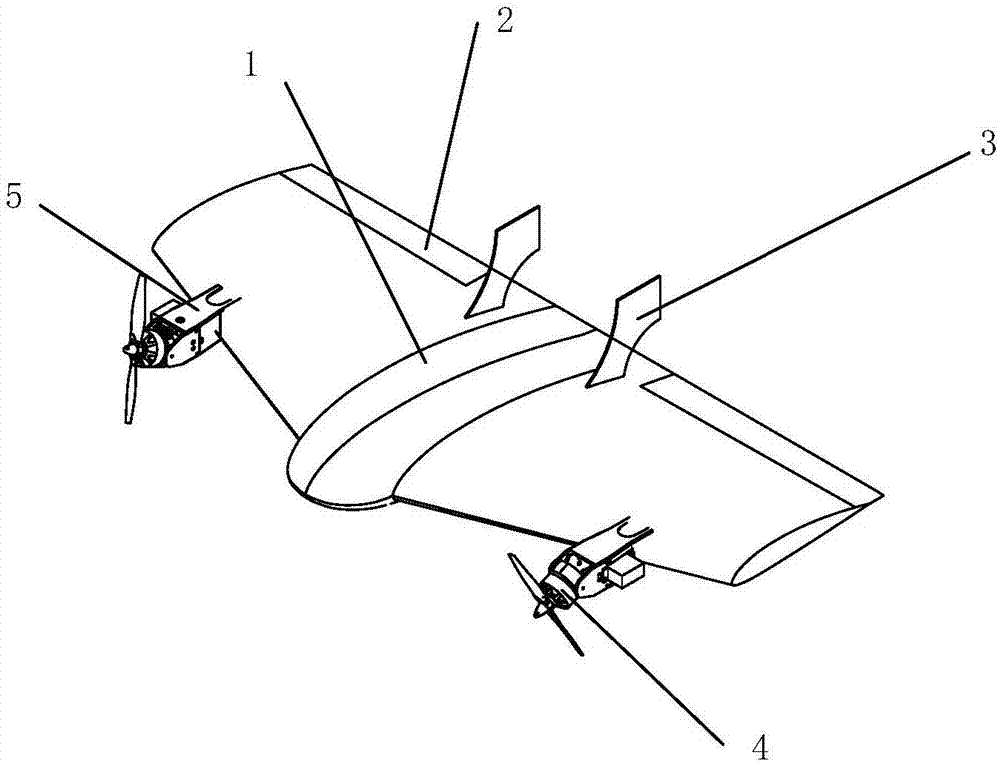

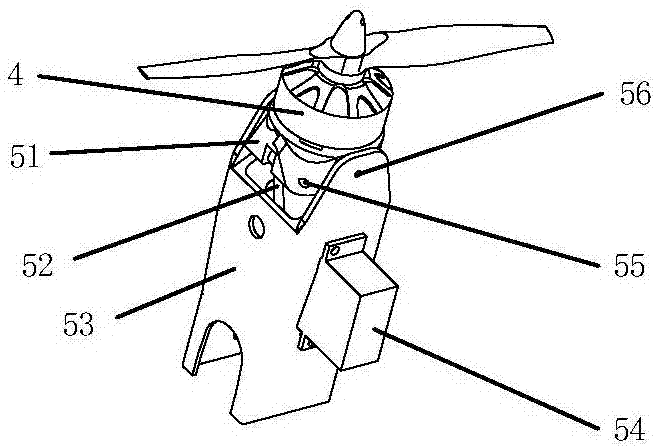

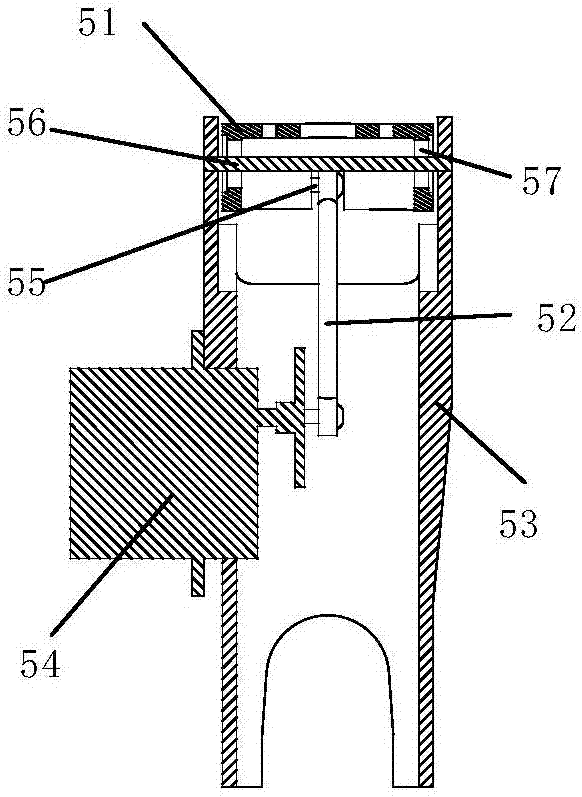

[0019] like Figure 1-4 As shown, the vertical take-off and landing UAV vector tension device, the vertical take-off and landing UAV is provided with a body 1, an aileron 2, a vertical tail 3, an engine 4, and a vector tension device 5. The vertical take-off and landing UAV vector tension device includes a swinging engine mount 51, a ball head tie rod 52, a fixed engine mount 53, a control steering gear 54, a ball head connected to an optical axis 55, and a support connected to an optical axis 56. Blue bearing 57, ball joint 58.

[0020] see Figure 1-4 , the fixed engine mount 53 is fixed on the leading edge of the wing of the body 1 through a mechanical connection, the control steering gear 54 is fixed on the fixed engine mount 53 by four screws, and the engine 4 is fixed on the swinging engine mount 51 by bolts Above, the oscillating engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com