Method for preparing polyethylene catalyst

A technology for polyethylene and catalyst is applied in the field of polyethylene catalyst to prepare high-branched polyethylene by using single ethylene as raw material, and the preparation field of polyethylene catalyst, and achieves the effects of reducing production cost, improving the difficulty of continuous polymerization and having good particle shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

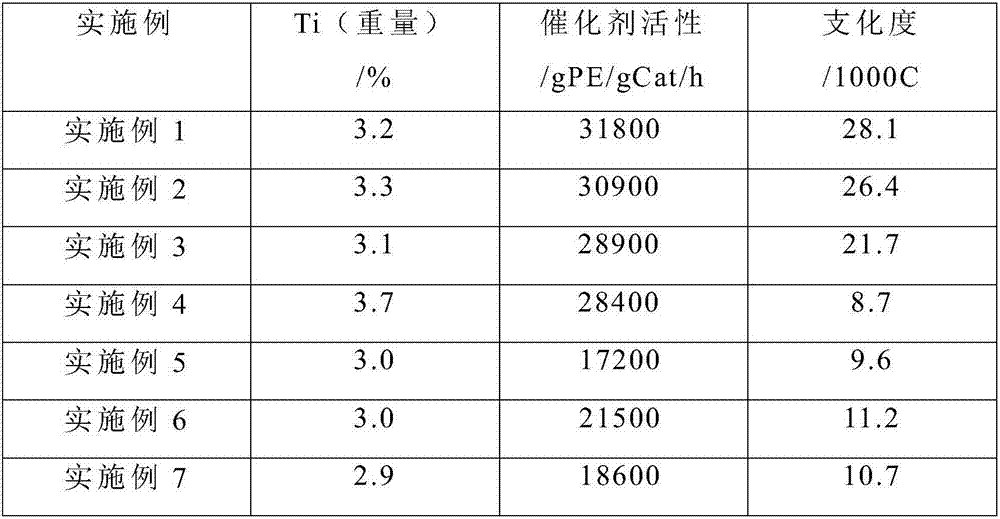

Examples

Embodiment 1

[0050] (1) prepare magnesium alkoxide solution

[0051] Add 100ml of cyclohexanone into a reaction vessel with a condensing device fully replaced with nitrogen, pass through nitrogen, slowly add 0.1 mole of ethoxymagnesium with the stirring turned on, and raise the temperature to 100°C for 3 hours. After the reaction is completed, Filtrate hot, and filter out the residue under the reaction vessel under the protection of nitrogen.

[0052] (2) Treatment of cyanocene compounds

[0053] Add 0.02 mol of IndCpZrCl to another reaction vessel fully replaced with nitrogen 2 , add 20ml of 10% MAO toluene solution under stirring, raise the temperature to 100°C and react for 4 hours, cool to room temperature after the reaction is completed, filter off the supernatant, wash with hexane, dry and add to the solution as described in (1) above for later use .

[0054] (3) Catalyst preparation

[0055] Add the solution obtained in the above (2) into a nitrogen-protected spray dryer, and se...

Embodiment 2

[0057] (1) prepare magnesium alkoxide solution

[0058] Add 85ml of isooctyl alcohol into a reaction vessel with a condensing device fully replaced with nitrogen, pass through nitrogen, slowly add 0.1 mole of ethoxymagnesium with the stirring turned on, and raise the temperature to 85°C for 3 hours. After the reaction is completed, Filtrate hot, and filter out the residue under the reaction vessel under the protection of nitrogen.

[0059] (2) Treatment of cyanocene compounds

[0060] In another reaction vessel fully replaced with nitrogen, add 0.01, mole Cp 2 ZrCl 2 , add 30ml of 10% MAO toluene solution under stirring, raise the temperature to 100°C and react for 4 hours, after the reaction is completed, cool to room temperature, filter off the supernatant, wash with hexane, dry and add to the solution as described in (1) above spare.

[0061] (3) Catalyst preparation

[0062] Add the solution obtained in the above (2) into a nitrogen-protected spray dryer, set the feed...

Embodiment 3

[0064] (1) prepare magnesium alkoxide solution

[0065] Add 110 ml of cyclohexanone and 1,3 propylene oxide mixture (volume ratio 1:1) into a reaction vessel with a condensing device fully replaced with nitrogen, feed nitrogen, and slowly add 0.03 mol of Magnesium methoxide was heated to 30°C for 3 hours to react. After the reaction was completed, it was heated and filtered, and the residue under the container was filtered out under the protection of nitrogen.

[0066] (2) Treatment of cyanocene compounds

[0067] Add 0.01 mole of Cp to another reaction vessel fully replaced with nitrogen 2 ZrMe 2 , add 20ml of 10% MAO toluene solution under stirring, raise the temperature to 100°C and react for 4 hours, cool to room temperature after the reaction is completed, filter off the supernatant, wash with hexane, dry and add to the solution as described in (1) above for later use .

[0068] (3) Catalyst preparation

[0069] Add the solution obtained in the above (2) into a nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com