Hydraulic energy conversion device for blade-free wind machine

An energy conversion device, wind turbine technology, applied in wind turbines, wind energy power generation, engine functions, etc., can solve the problems of noise and visual pollution, impact on the ecological environment, and high installation costs, and achieve the effect of no noise pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

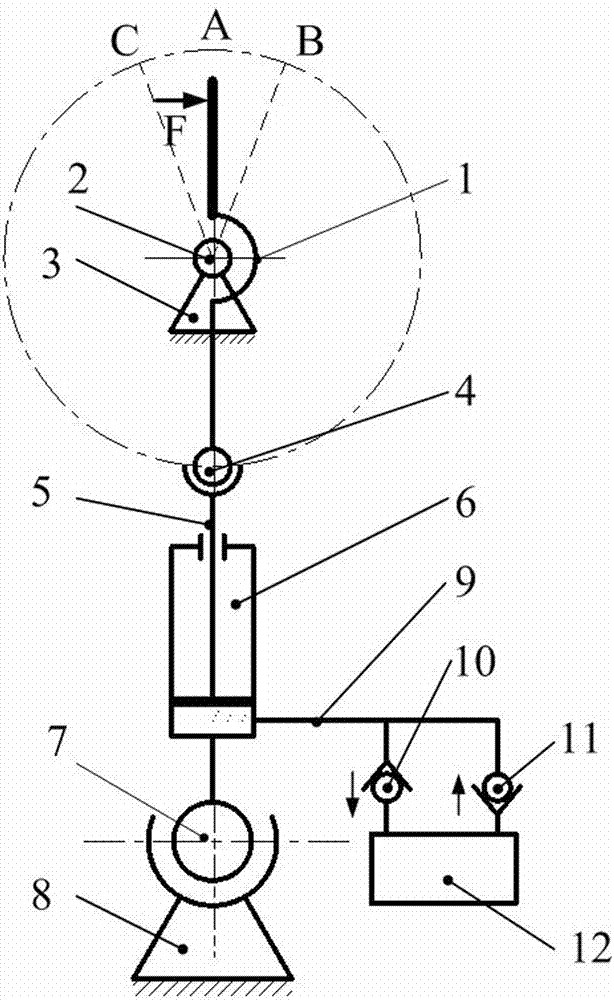

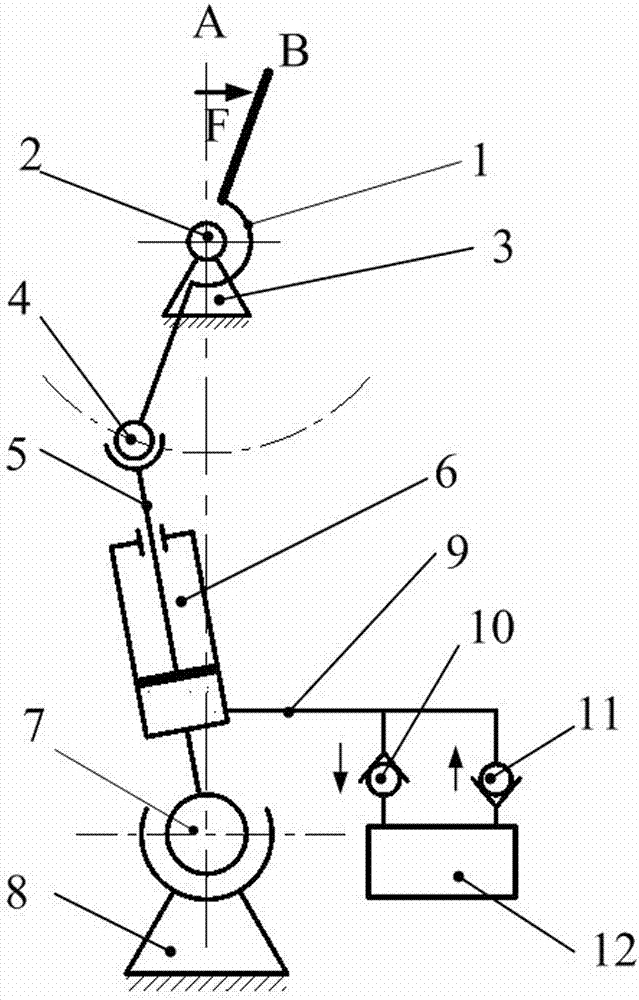

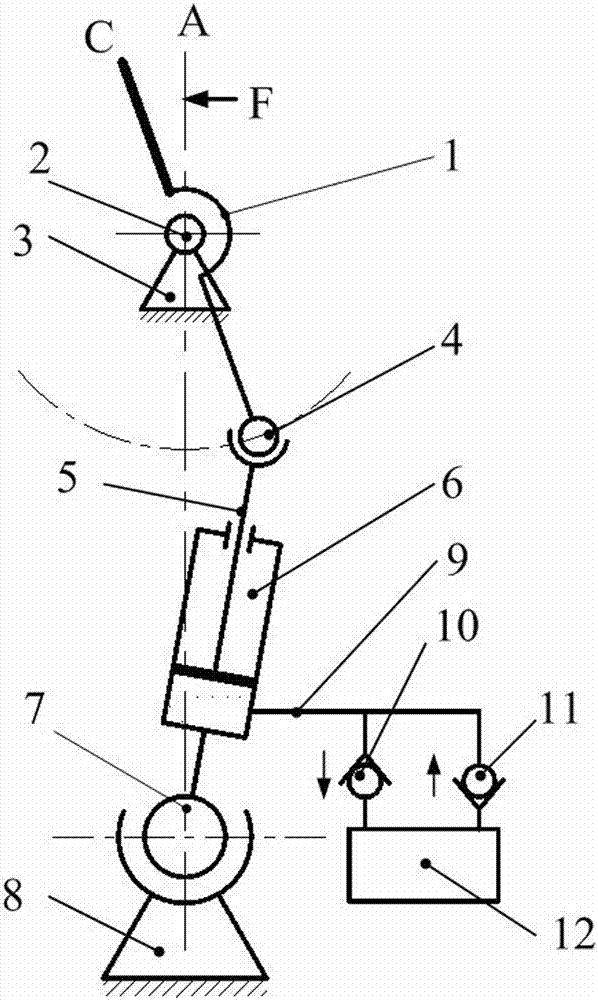

[0023] Embodiment 1, the present invention mainly includes a wind power tower 1, a spherical hinge I2, an upper base 3, a ball joint 4, a piston assembly 5, a cylinder 6, a spherical hinge II7, a lower base 8, a one-way valve I10 and a one-way Valve II11, hydraulic pipe 9 and hydraulic motor 12; the wind tower 1 is fixed on the upper machine base 3 through the spherical hinge I2, the wind tower 1 is connected with the piston assembly 5 through the ball joint 4, and the piston assembly 5 is arranged in the cylinder body 6 , when the wind tower 1 deflects and swings, it drives the piston assembly 5 to move up and down in the cylinder body 6, so that the liquid in the cylinder body 6 is sucked and discharged; the cylinder body 6 is fixed on the lower machine base 8 through the spherical hinge II7, hydraulic One end of the pipe 9 is connected to the cylinder body 6, and the other end is divided into two branches, which are respectively connected to the hydraulic motor through the c...

Embodiment 2

[0024]Embodiment 2, the wind tower 1 is fixed on the upper frame 3 through the spherical hinge I2, and the wind tower 1 can only deflect around the upper frame 3 and cannot rotate around the longitudinal axis of the wind tower 1 itself, thereby preventing the The rotation of the wind tower 1 results in loss of wind energy acquisition. The use of spherical hinge I2 to fix the wind tower 1 on the upper support 3 can ensure that the direction of the wind force received by the wind tower 1 is not limited, and any wind force in the same direction can cause the wind tower 1 to deflect at the same angle and output the same output. rotational kinetic energy. The spherical hinge I2 is used to fix the wind tower 1 on the upper support 3, so that the installation of the bladeless wind turbine is not restricted by the incoming flow direction. refer to Figure 1 to Figure 3 , all the other are with embodiment 1.

Embodiment 3

[0025] In Embodiment 3, the wind tower 1 is directly connected to the piston assembly 5 through the ball joint 4, wherein the piston assembly 5 can only deflect around the ball joint 4, but cannot rotate around the longitudinal axis of the piston assembly 5 itself. On the one hand, it can prevent the piston assembly from The assembly 5 itself rotates to cause increased wear and energy loss; on the other hand, when the wind tower 1 deflects in a certain direction under the action of wind, it can ensure that the piston assembly 5 is correspondingly deflected in the opposite direction to the deflection of the wind tower 1. refer to Figure 1 to Figure 3 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com