Self-balance-weight faucet handle and production technology thereof

A handle and faucet technology, which is applied in the field of self-balancing faucet handle and its production technology, can solve the problems of low overall structural strength, complex manufacturing process, short service life, etc., achieve simple structure, simple manufacturing process, and meet mass production Processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

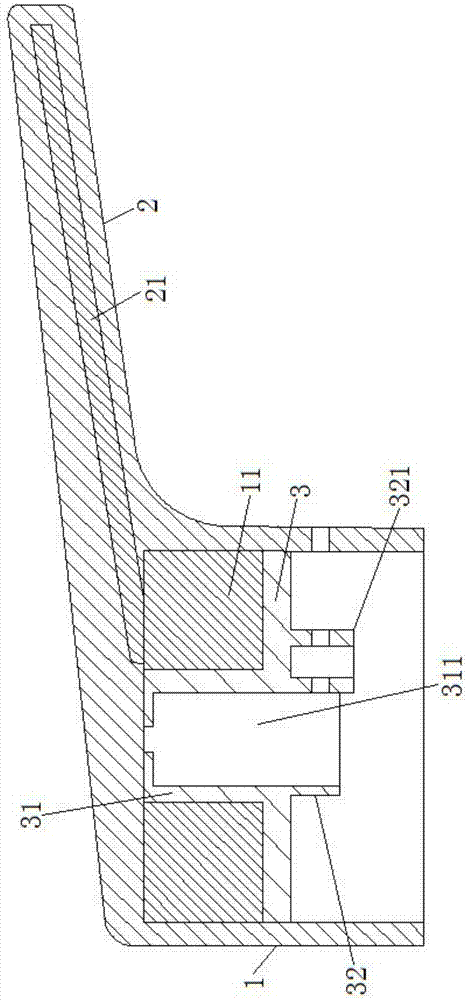

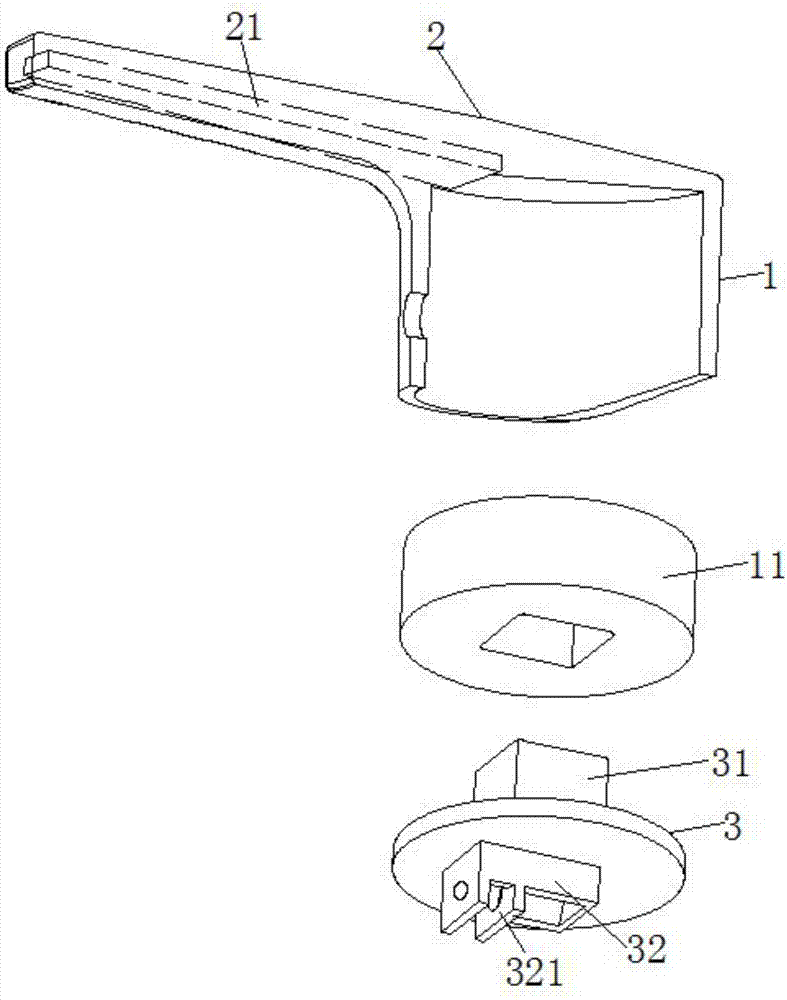

[0035] Embodiment one: if figure 1 and 2 As shown, the self-balancing faucet handle of this embodiment includes a handle body 1, a handle 2, and a cover 3;

[0036] The above-mentioned handle 2 is integrally formed on the above-mentioned handle body 1, the above-mentioned handle body 1 is a cylindrical structure with an open lower end, a first counterweight 11 is arranged in the above-mentioned handle body 1 close to the closed end, and the above-mentioned cover 3 is arranged on On the inner wall of the above-mentioned handle body 1, and press the above-mentioned first counterweight 11 on the closed end of the above-mentioned handle body 1;

[0037] The upper end of the cover 3 is provided with a positioning block 31, and the above-mentioned first counterweight 11 is provided with a positioning hole passing through it up and down and corresponding to the above-mentioned positioning block 31, and the above-mentioned positioning block 31 extends into the above-mentioned positio...

Embodiment 2

[0046] Embodiment 2: A kind of production process of the self-balancing faucet handle as described above in Embodiment 1, comprising the following steps:

[0047] Step 1: Weld and fix the first counterweight 11 and the second counterweight 21, and ensure that one end of the second counterweight 21 is welded to the top side of the first counterweight 11;

[0048] Step 2: Insert the cover 3 into the above-mentioned positioning hole through the positioning block 31 at the upper end, insert the nut into the above-mentioned nut installation groove 321, and place the entire first counterweight 11, the second counterweight 21 and the sealing The cover 3 is put into the mold upside down;

[0049] Step 3: Integral injection molding, specifically, injection molding liquid is injected into the mold through the injection molding channel at the connecting portion 32 of the valve stem, and the faucet handle is formed by integral injection molding.

[0050] The process is simple to manufact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com