Indoor simulation test device for studying impact of piping on tunnel and grouting control

A simulation device and simulation test technology, applied in measurement devices, instruments, surveying, mapping and navigation, etc., can solve problems such as inaccurate response, inability to consider the interaction between soil and seepage, inability to analyze piping from a mechanism, etc. Good, highly scalable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail through a preferred example below in conjunction with the accompanying drawings.

[0017] First, make a model box 1, a tunnel lining model 2, a piping simulation device, and a grouting simulation device.

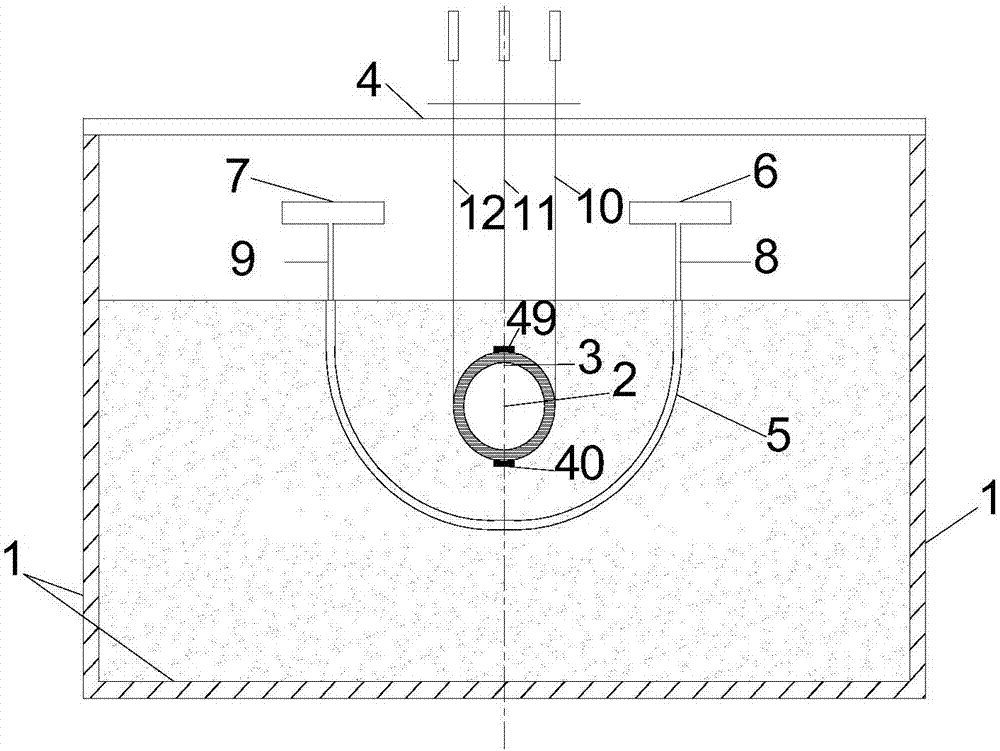

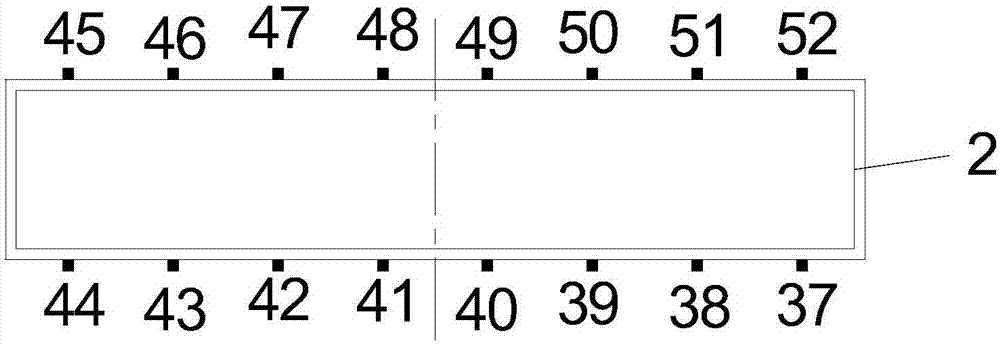

[0018] figure 1 It is a schematic diagram of the simulation test device in the model box in the embodiment of the present invention, as figure 1 As shown, the shape of the model box 1 is a cuboid, and the internal space size is 800 mm × 500 mm × 500 mm (length × width × height), which is composed of five aluminum alloy plates with a thickness of 15 mm. The tunnel lining model 2 is a four-section hollow aluminum alloy tube 3 with an outer diameter of 80 mm, an inner diameter of 70 mm, a wall thickness of 5 mm, and an axial segment length of 100 mm. The lining model segment has an outer diameter of 100 mm and an inner diameter of 70 mm.

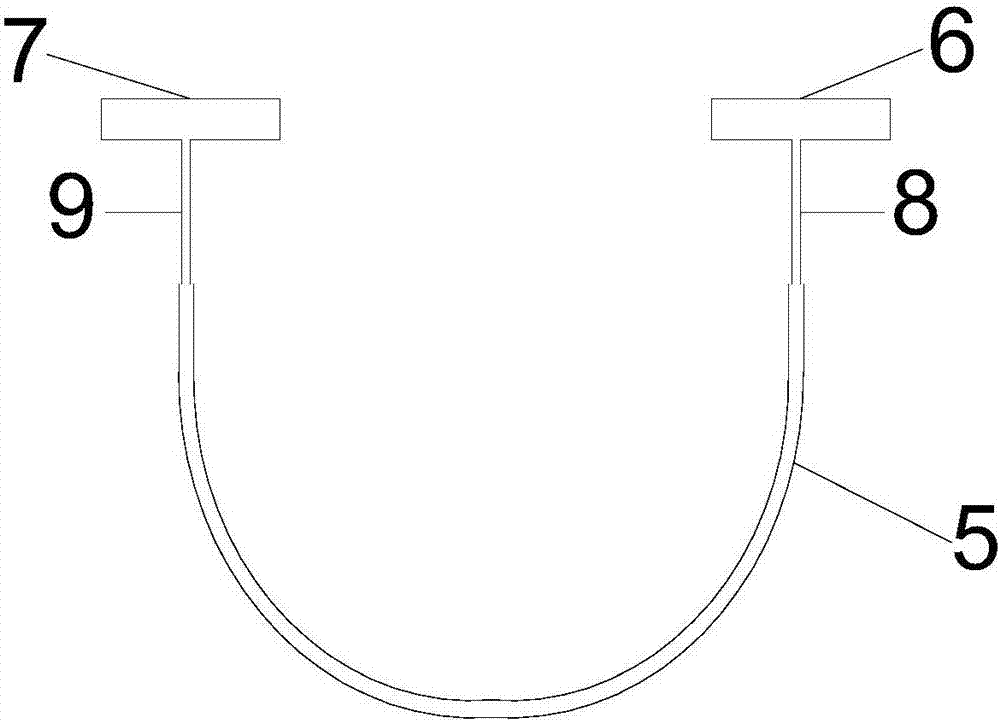

[0019] figure 2 It is a schematic diagram of the piping simulation dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com