Organic light-emitting diode with linearly polarized emission

A technology of light-emitting diodes and organic light-emitting layers, which is applied in the direction of organic light-emitting devices, organic light-emitting device structures, and electric solid-state devices, and can solve the problems of inability to realize the conversion of the polarization mode of OLED devices, complicated preparation process, and high cost of electron beam etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

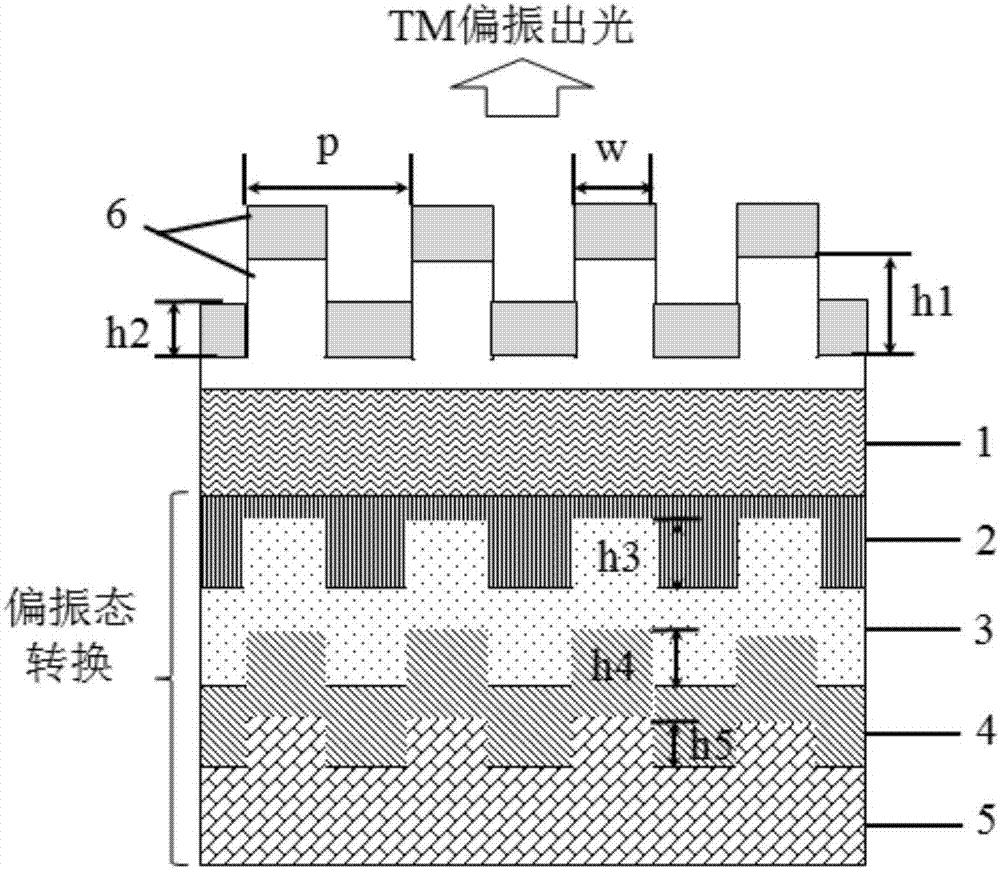

[0031] Taking a flexible and bendable green OLED device (luminescence peak at 520nm) as an example to describe in detail, in this structure, the substrate 1 is the flexible material polyethylene terephthalate / ITO, and the first transport layer 2 is PEDOT :PSS, the organic light-emitting layer 3 is Alq 3: C545T, the second transport layer 4 is Alq3, and the composite back electrode 5 is LiF / Al. The structure of the green OLED device is: polyethylene terephthalate / ITO(120nm) / PEDOT:PSS(80nm) / NPB(40nm) / Alq3:C545T(20nm) / Alq3(40nm) / LiF(1nm) / Al (100nm).

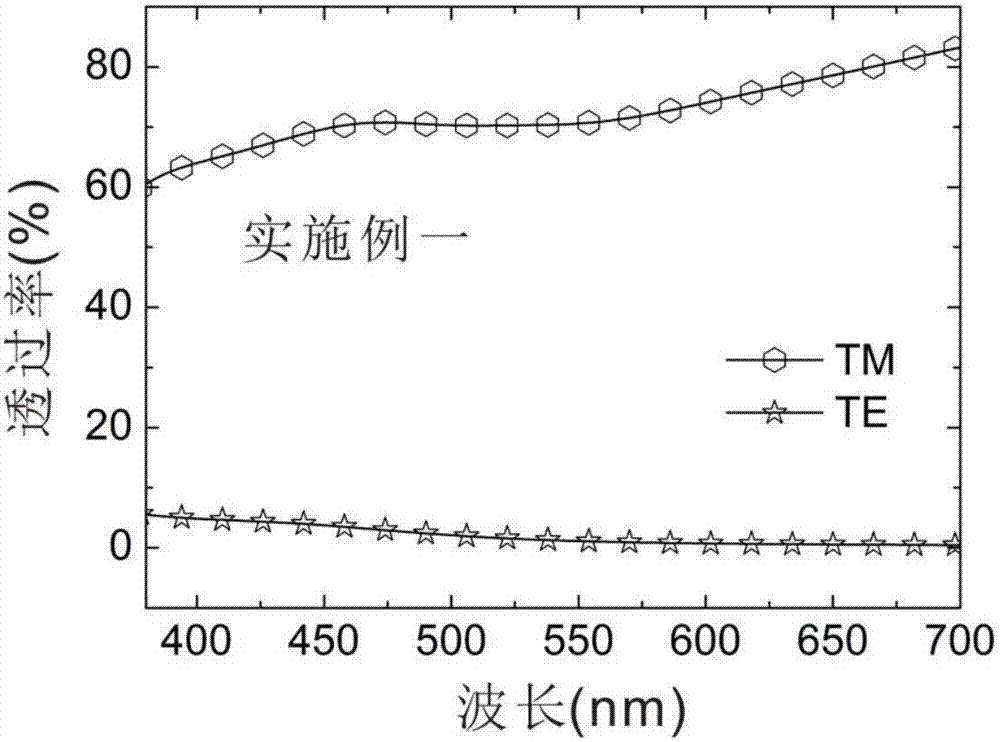

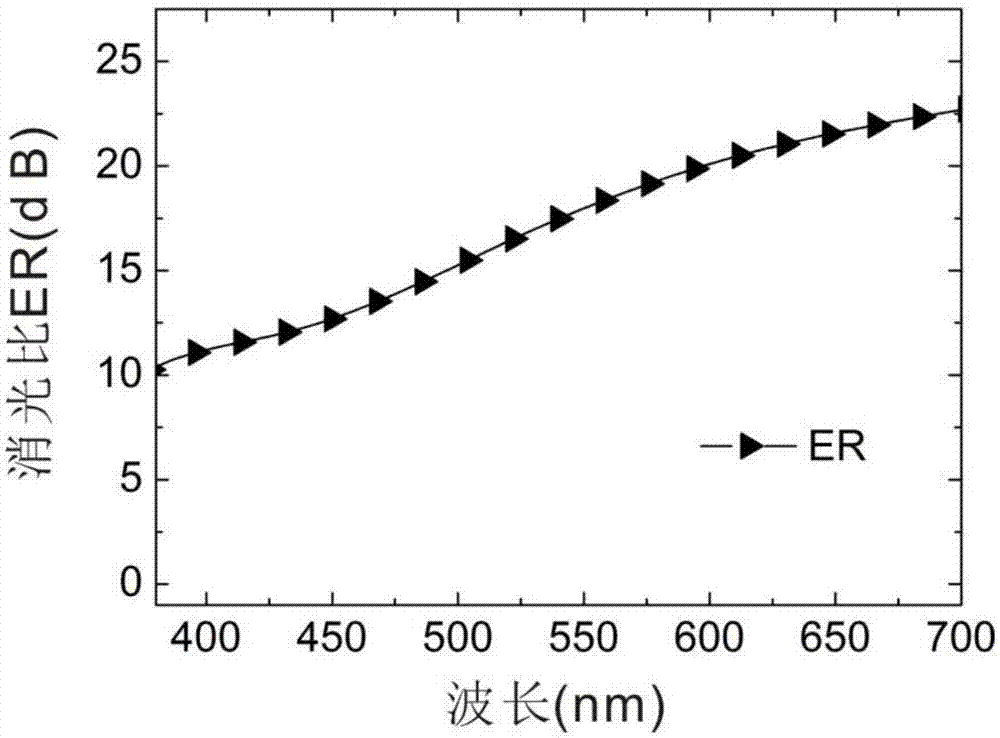

[0032] Firstly, according to the finite element difference algorithm, the morphology of the nano-grating and dielectric metal grating is specifically designed. The optimal polarization extinction ratio and TM wave transmittance of the green light device are judged as criteria. Through theoretical calculation and optimization, the period and duty ratio of the dielectric metal grating of this embodiment are 100nm and 0.54 respecti...

Embodiment 2

[0038] Taking a rigid substrate red OLED device (luminescence peak at 520nm) as an example to describe in detail, in this structure, the substrate 1 is glass / ITO, the first transport layer 2 is a laminated structure of PEDOT:PSS / NPB / TCTA, organic Emitting layer 3 is Ir(MDQ) 2 (acac), the second transport layer 4 is TmPyPB, and the composite back electrode 5 is LiF / Al. The structure of the green OLED device is: glass / ITO(120nm) / PEDOT:PSS(80nm) / NPB(40nm) / TCTA(15nm) / Ir(MDQ) 2 (acac)(0.1nm) / TmPyPB(40nm) / LiF(1nm) / Al(100nm).

[0039] Firstly, according to the finite element difference algorithm, the morphology of the nano-grating and dielectric metal grating is specifically designed. The optimal polarization extinction ratio and TM wave transmittance of the green light device are judged as criteria. Through theoretical calculation and optimization, the period of the nano-grating and the period and duty ratio of the dielectric metal grating in this embodiment are both 200nm and 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Extinction ratio | aaaaa | aaaaa |

| Extinction ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com