Structure adopting bevel gear set for driving four-sided grinding heads and polishing head with same

A gear set and bevel gear technology, applied in the field of polishing head, can solve the problems of long time required for polishing operation, long time required for polishing, and reduced productivity, so as to improve streamline and quality, facilitate production and assembly, The effect of reducing processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

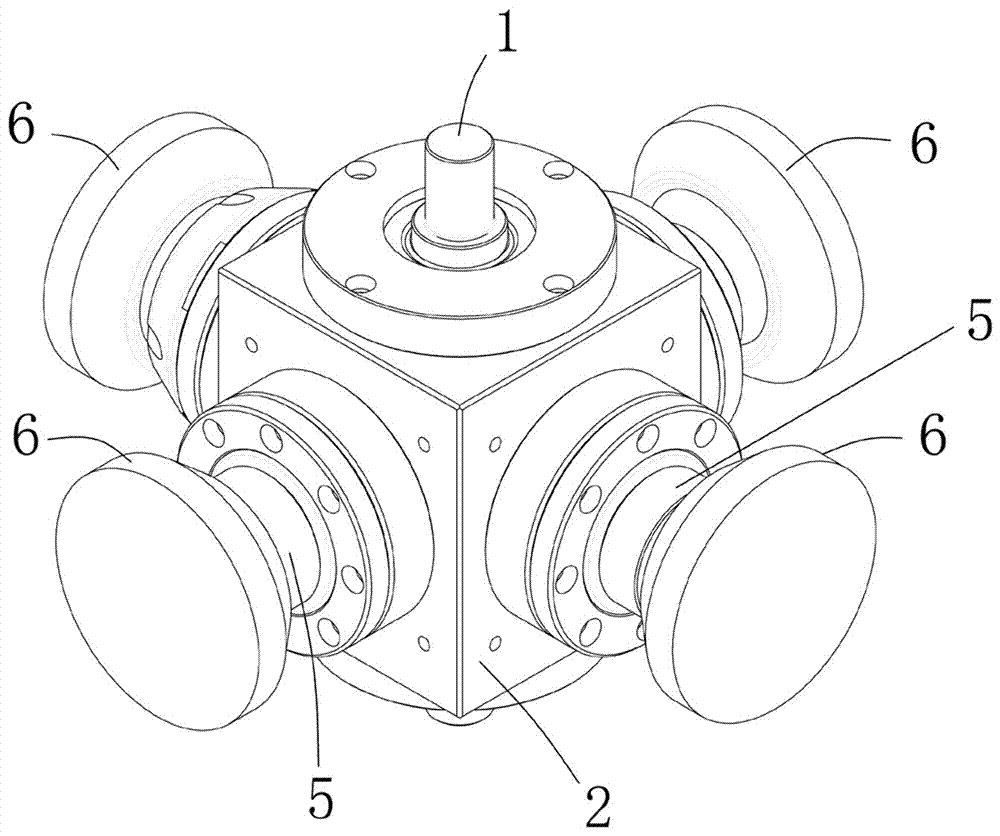

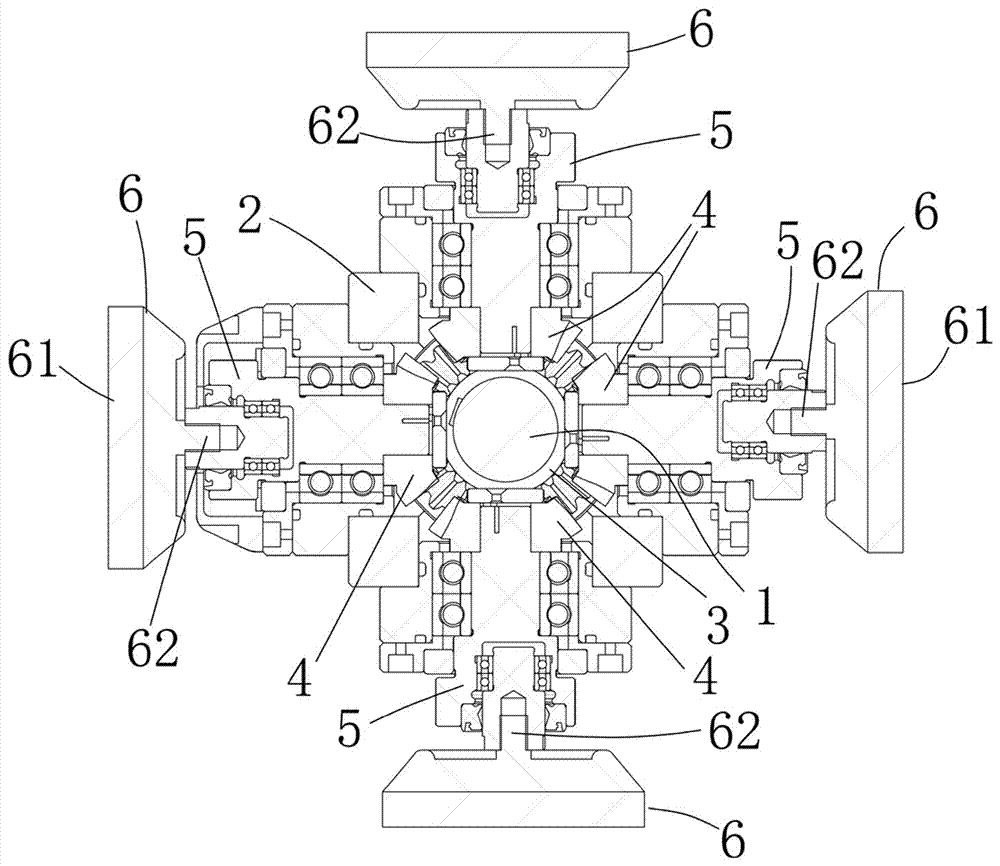

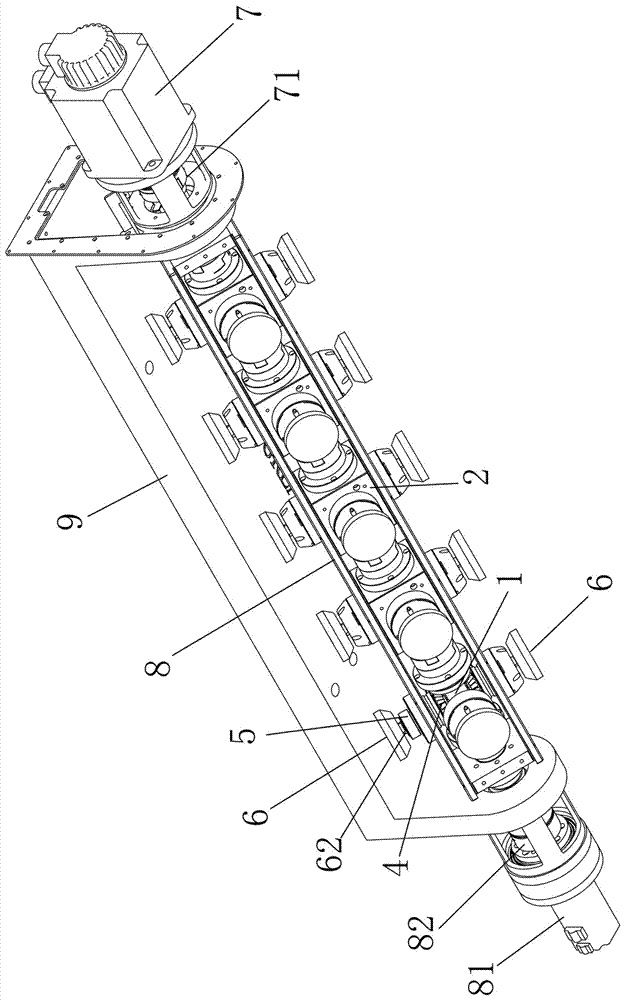

[0017] refer to figure 1 , 2 As shown, the structure of the bevel gear set driving the four-sided grinding head provided by the present invention has a main shaft 1, the main shaft 1 is installed on the gear box 2 through a bearing, and one end of the main shaft 1 extends out of the gear box 2 to connect polishing motor ( figure 1 , 2 omitted), the main shaft 1 in the gearbox 2 is provided with a main bevel gear 3, and the main bevel gear 3 meshes with four auxiliary bevel gears 4. The auxiliary bevel gear 4 is installed on the auxiliary rotating shaft 5, the auxiliary rotating shaft 5 is installed on the gear box 2 through bearings and is perpendicular to the main rotating shaft 1, one end of the auxiliary rotating shaft 5 exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com