Compound driven shoulder joint

A shoulder joint and driver technology, applied in the field of compound drive shoulder joints, can solve the problems of cumbersome operation, insufficient precision, and high precision of heavy load of the robot arm, and achieve the effect of flexible work and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

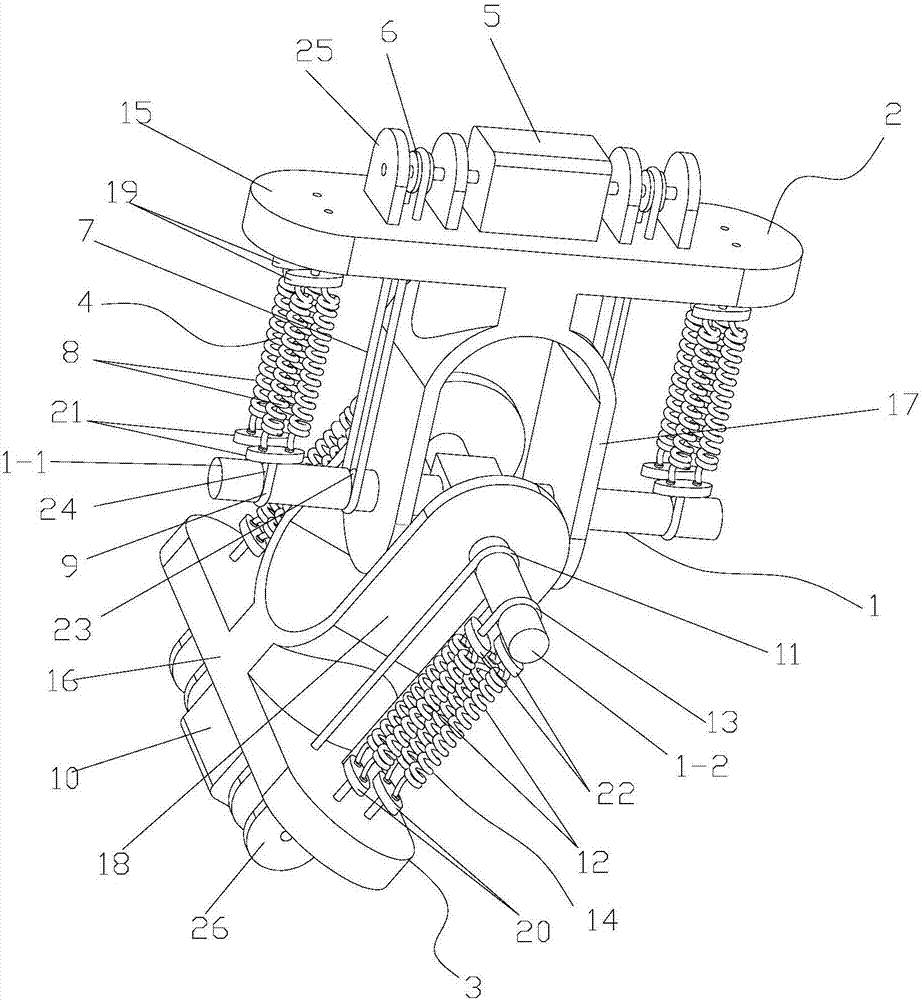

[0018] figure 1 It is a schematic diagram of the overall structure of the present invention, as shown in the figure: the composite drive shoulder joint of this embodiment includes a cross shaft 1, a movable hinge frame 2 and a fixed hinge frame 3, and is respectively used to drive the swing motion and pitch of the movable hinge frame 2 The swing drive part and the pitch drive part of the movement; the movable hinge frame 2 rotates with the first shaft body 1-1 of the cross shaft 1, and the second shaft body 1-2 of the cross shaft 1 rotates with the fixed hinge frame 3; as shown in the figure As shown, the cross shaft 1 is composed of the first shaft body 1-1 and the second shaft body 1-2 connected in a cross shape. The movable hinge frame 2, the fixed hinge frame 3 and the cross shaft 1 together form a Hooke hinge structure. , the fixed hinge frame 3 is fixed, and the movable hinge frame 2 is fixed with the big arm of the robot. The movable hinge frame 2 can produce rotation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com