Method for calculating mass concentration of ammonium sulfate liquid injection for ion-type rare earth in-situ leaching

An ion-type rare earth and in-situ leaching technology, applied in the direction of improving process efficiency, etc., can solve the lack of theoretical basis and other problems, and achieve a scientific and reasonable effect of injection liquid mass concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

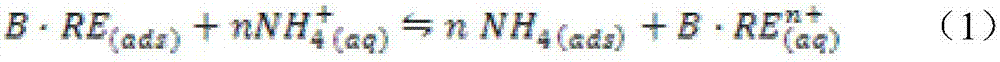

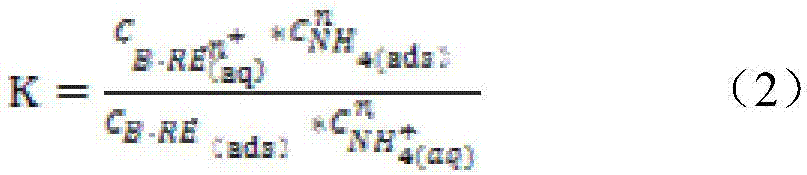

Method used

Image

Examples

Embodiment Construction

[0037] The present invention conducts an undisclosed experiment in a rare earth mining area in southern Jiangxi, takes ore samples from different locations on the spot, mixes them, and prepares representative Xinfeng ion-type rare earth ore samples. The cup leaching test was carried out on the ore sample to obtain key parameters, and the calculation results were used as the conditions of the column leaching test to verify the accuracy of the calculation results. The specific implementation steps are as follows:

[0038] Step 1: Cup Dip Test

PUM

| Property | Measurement | Unit |

|---|---|---|

| void ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com