Testing method and apparatus of corrosive wear resistance of dissimilar metal friction matching pair

A technology for corrosion wear and dissimilar metals, applied in the field of test methods and test devices for corrosion and wear performance of dissimilar metal friction partners, can solve problems such as inability to test galvanic corrosion, and achieve the effect of convenient and accurate galvanic corrosion behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

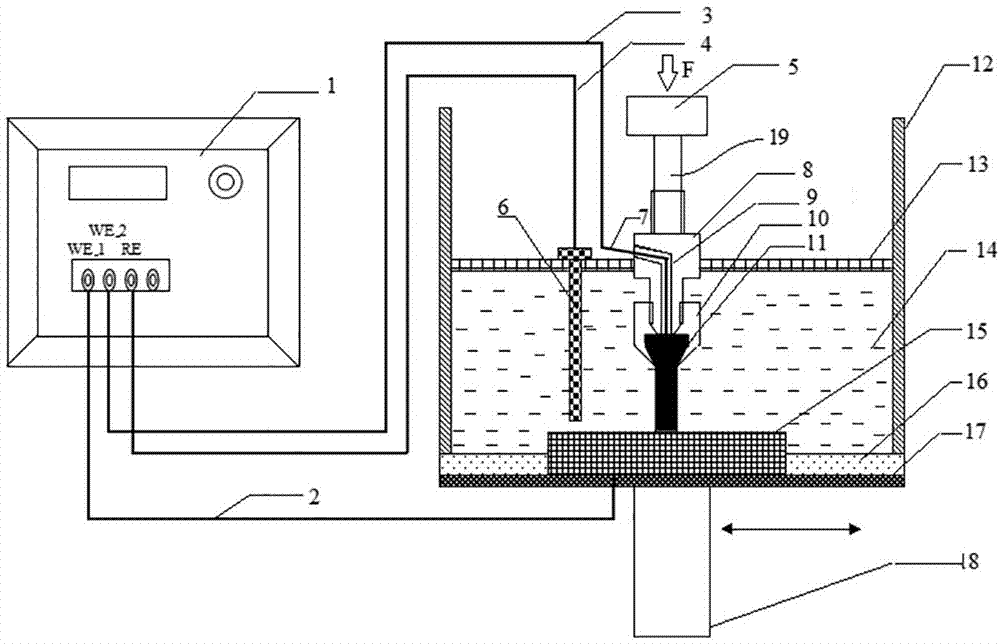

[0019] An embodiment of the corrosion and wear performance test of dissimilar metal friction partners in the present invention is as follows figure 1 As shown, it mainly includes a sample table 17, an O-ring 16, a solution tank 12, a second sample holder, a reference electrode 6, a ZRA galvanic corrosion meter 1 and a friction and wear test system. Among them, the O-shaped sealing ring 16 is arranged on the sample table 17 to form the first sample fixing seat, and the first metal sample 15 is sealed and fixed in the O-shaped sealing ring 16, and is in contact with the metal test table 17. working electrode. The second metal sample 11 is a cylindrical structure, connected to the loading head of the friction and wear experimental testing system through the second sample holder, and its tail end is provided with a circular frustum structure with a small front and a large rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com