Preparation method of instant fish bone dipping sauce

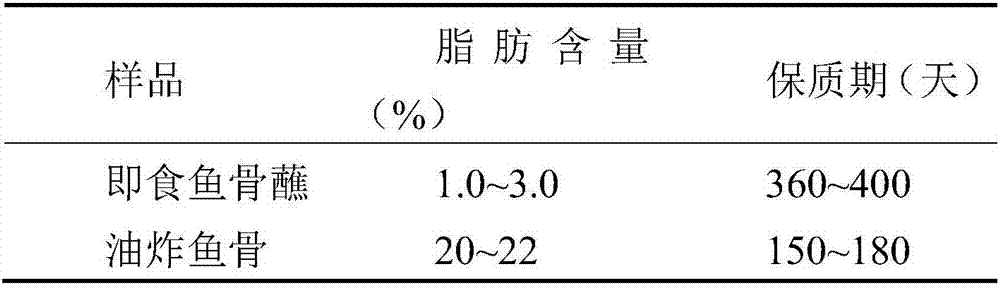

A fishbone and roasting technology is applied in the field of preparation of ready-to-eat fishbone dips, which can solve the problems of long softening time at high temperature, high fat content in the product, easy occurrence of oxidative rancidity, etc., so as to improve the softening efficiency, shorten the processing cycle, and shorten the softening time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In the present embodiment, the preparation method of instant fish bone dipping is as follows:

[0021] (1) Soften

[0022] Cut fresh or thawed central cod bones into 1.0cm long and 1.0cm wide blocks, and then wash off the residual blood, fascia, dirt, etc. on the fish bones to obtain pretreated cod bones; put the pretreated cod bones in Put it into 0.05% citric acid solution with a mass concentration of 0.8 times its mass, soften it at 115° C. for 30 minutes, put it in drinking water after removing it, rinse repeatedly to remove the fish meat attached to it, and obtain softened cod bone after draining;

[0023] (2) Cooking

[0024] Put the softened cod bone obtained in step (1) into the cooking liquid whose mass is 1.0 times the volume, keep the soup at 90°C for 35 minutes, and then collect the soup until dry to obtain the boiled cod bone; the cooking liquid is obtained by mass percentage Content (the same below) 2% white sugar, 2% cooking wine, 0.5% edible salt, 0.5%...

Embodiment 2

[0032] In the present embodiment, the preparation method of instant fish bone dipping is as follows:

[0033] (1) Soften

[0034] Cut the axial bone of fresh or thawed salmon into pieces with a length of 1.2cm and a width of 1.2cm, and then wash off the residual blood, fascia, dirt, etc. on the fish bones to obtain pretreated salmon bones; put the pretreated salmon bones into Put it into 0.1% acetic acid solution with a mass concentration of 1.0 times its mass, soften it at 118° C. for 22 minutes, put it in drinking water after removing it, rinse repeatedly to remove the attached fish flesh, and obtain softened salmon bone after draining;

[0035] (2) Cooking

[0036] Put the softened salmon bone obtained in the step (1) into a cooking liquid whose mass is 1.2 times the volume, keep the soup at 95°C for 30 minutes, and then collect the soup until dry to obtain the boiled salmon bone; the cooking liquid is made of 3% White sugar, 3% cooking wine, 0.8% edible salt, 0.8% vinega...

Embodiment 3

[0044] In the present embodiment, the preparation method of instant fish bone dipping is as follows:

[0045] (1) Soften

[0046] Cut fresh or thawed perch central axis bone into 1.5cm long and 1.5cm wide blocks, then wash off the residual blood, fascia, dirt, etc. on the fish bone to obtain pretreated cod bone; put the pretreated perch bone into Put it into a 0.2% citric acid solution with a mass concentration of 1.2 times its mass, soften it at 121°C for 15 minutes, put it in drinking water after pulling it out, rinse repeatedly to remove the fish meat attached to it, and obtain the softened perch bone after draining;

[0047] (2) Cooking

[0048] Put the softened perch bone obtained in the step (1) into a cooking solution whose mass is 1.5 times the volume, keep the soup at 98°C for 25 minutes, and then collect the soup until dry to obtain the cooked perch bone; the cooking solution is made of 4% White sugar, 4% cooking wine, 1.0% edible salt, 1.0% vinegar, 0.3% white pep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com