Wire electric discharge machine

A wire electric discharge machine and electric discharge processing technology are applied to electric processing equipment, metal processing equipment, circuits, etc., and can solve problems such as wrinkles on the processing surface and time loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, embodiments of the present invention will be described together with the drawings.

[0041] The present invention predicts the occurrence of a problem in a wire electrical discharge machine in advance based on the image information obtained by the image information collecting unit and outputs a warning, thereby preventing the occurrence of the problem and the consequent stoppage of the electrical discharge machining.

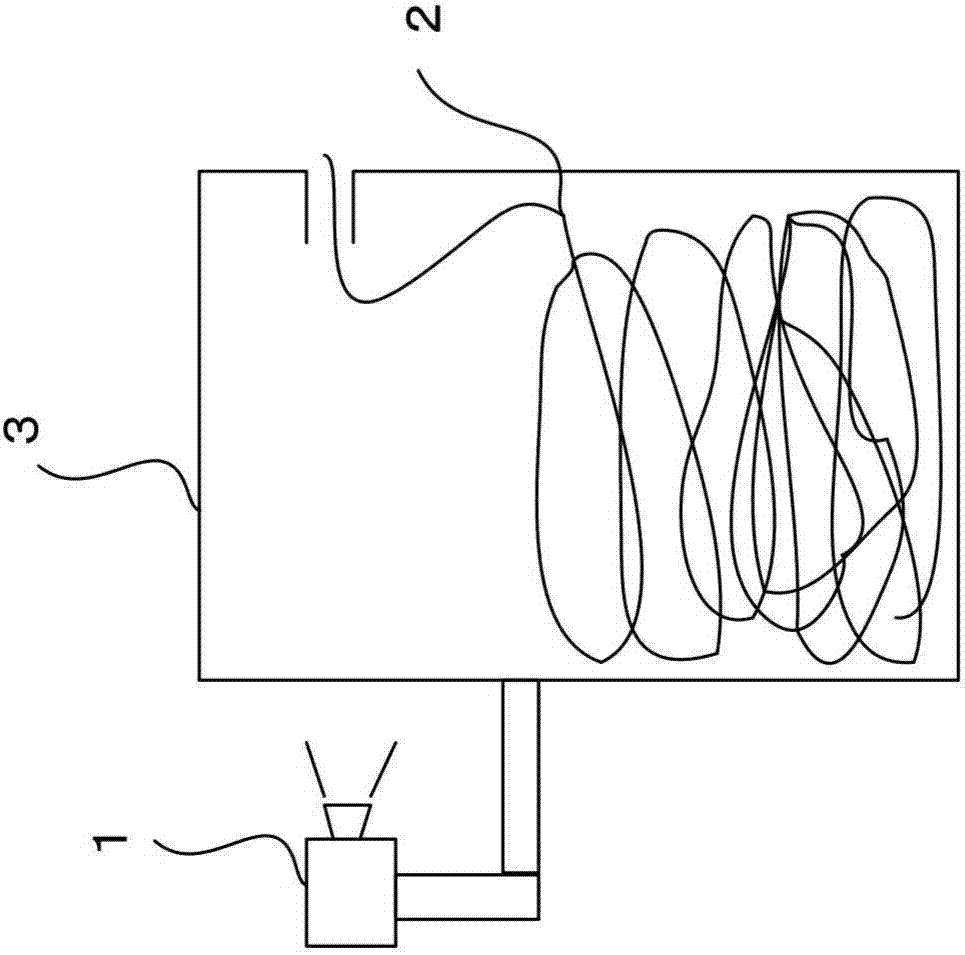

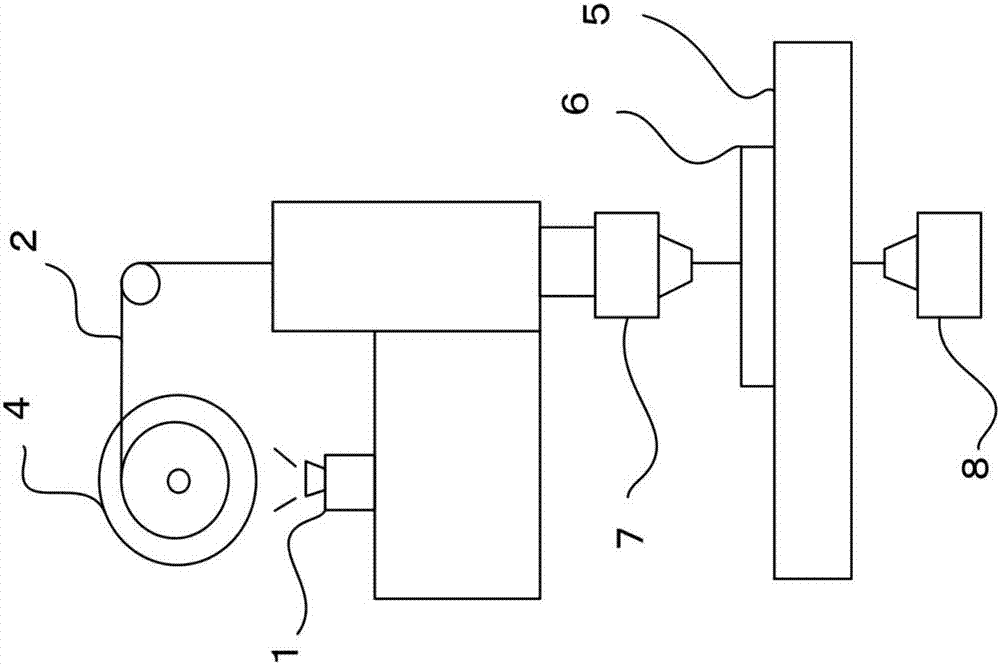

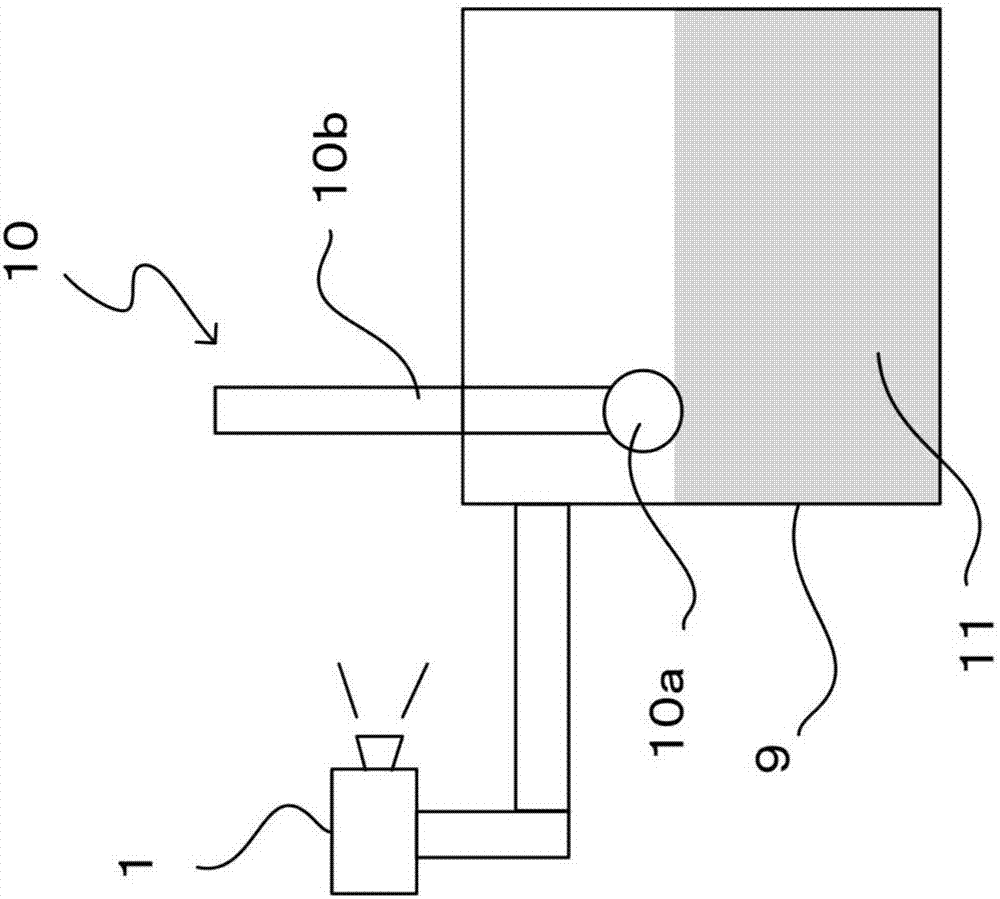

[0042] Figure 1A It is an explanatory diagram of the image information of the accumulation state of the thread in the thread collection box collected by the image information collecting unit 1, Figure 1B It is an explanatory diagram for collecting image information of the wire remaining state of the bobbin by the image information collecting unit 1, Figure 1C It is an explanatory diagram for collecting image information of the water level state of the machining fluid in the water storage tank of the machining fluid by the image information...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com