Concrete prefabricated component automatic health preservation device

A technology of prefabricated components and concrete, which is applied in the manufacture of tools, ceramic molding machines, etc., which can solve the problems of excessive labor and easy damage of biological materials, and achieve the effects of reducing the waste of biological materials, improving the effect of health care, and reducing the use of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the implementations shown in the drawings, but it should be noted that these implementations are not limitations of the present invention, and those of ordinary skill in the art based on the functions, methods, or structural changes made by these implementations Equivalent transformations or substitutions all fall within the protection scope of the present invention.

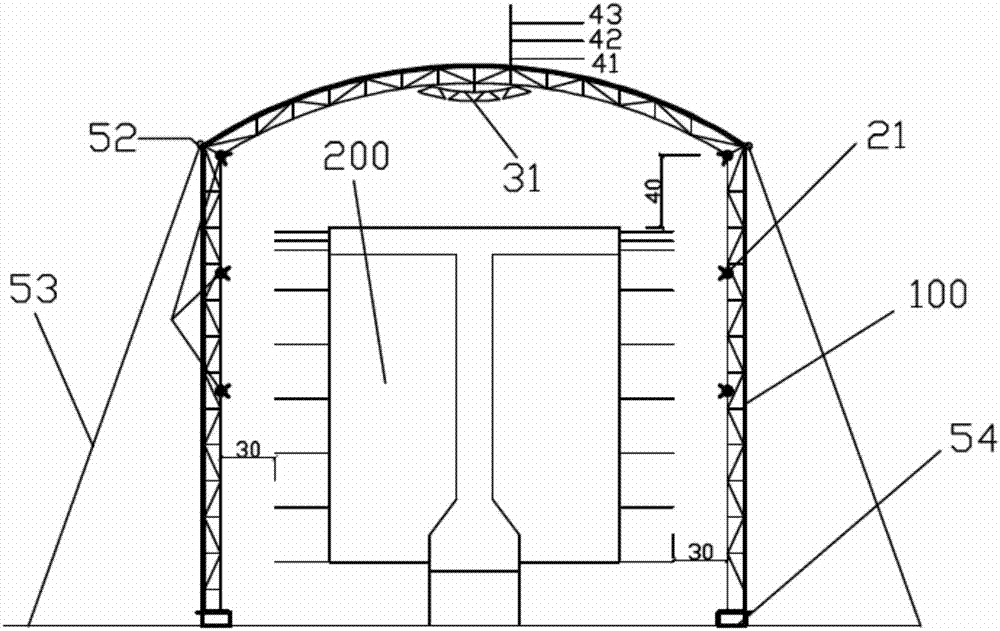

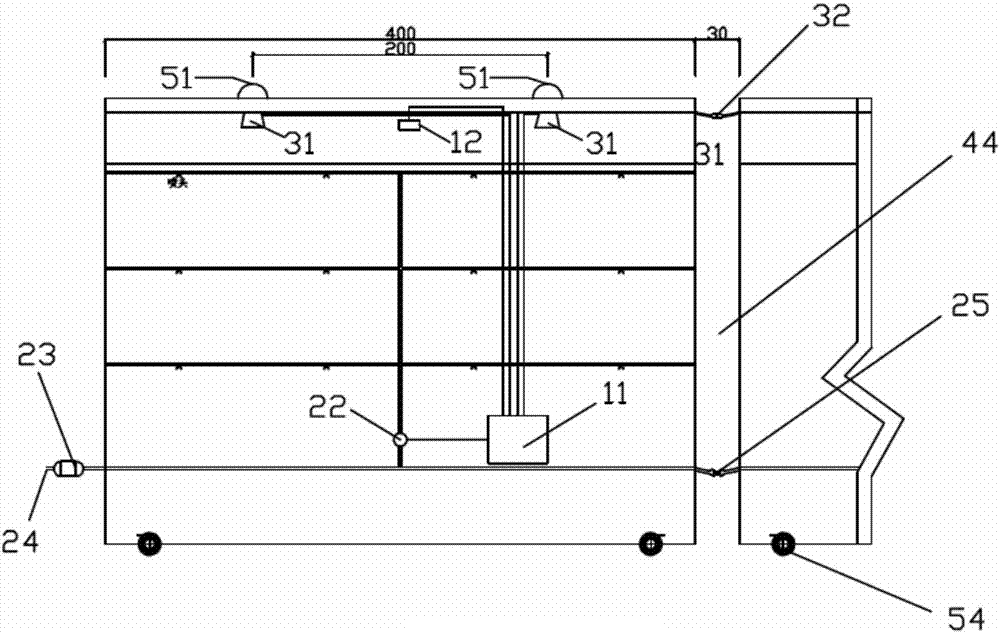

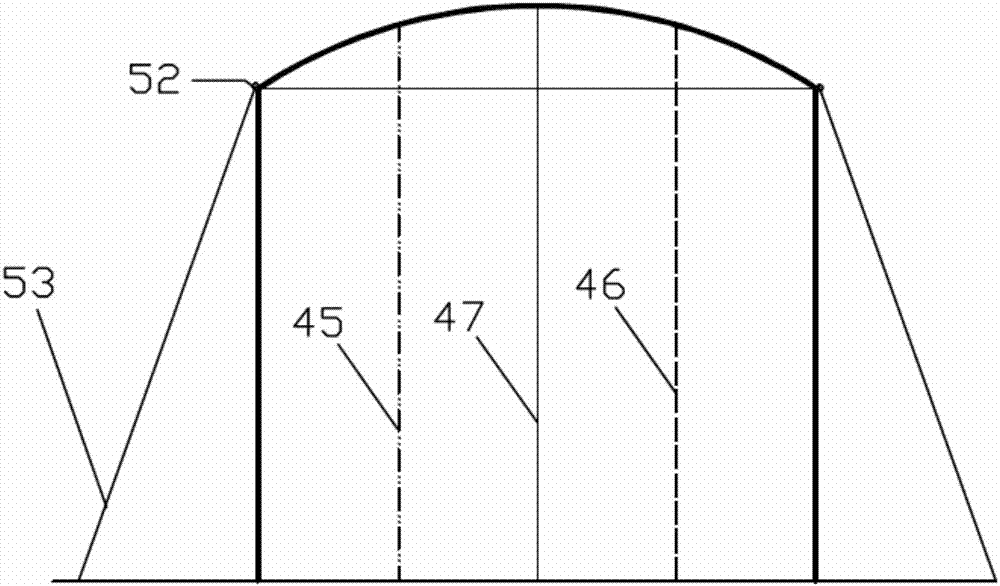

[0023] ginseng Figure 1 to Figure 4 As shown, this embodiment provides an automatic health preservation device for prefabricated concrete components, including at least one standard health preservation shed section 100 coated with a heat-retaining and moisture-retaining layer. Sprinklers and heating devices are arranged in the health care shed section 100, which are connected to the control system to automatically control the temperature and humidity in the standard health care shed section 100 through the control system, so as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com