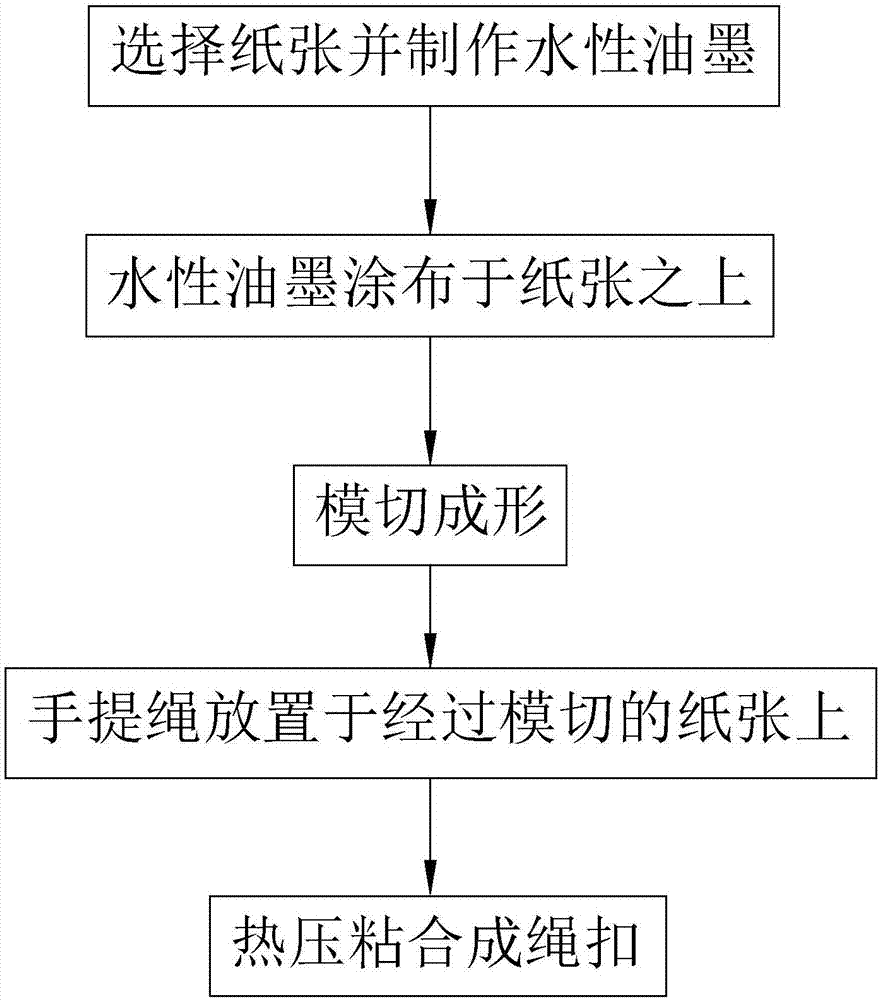

Method for replacing traditional rubber buckle with cord buckle of paper environment-friendly bag

An environmentally friendly bag and rope buckle technology, applied in the direction of paper, cardboard items, ink, etc., can solve the problems of increasing the recycling process and increasing the recycling cost, and achieve the effect of saving the recycling process and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

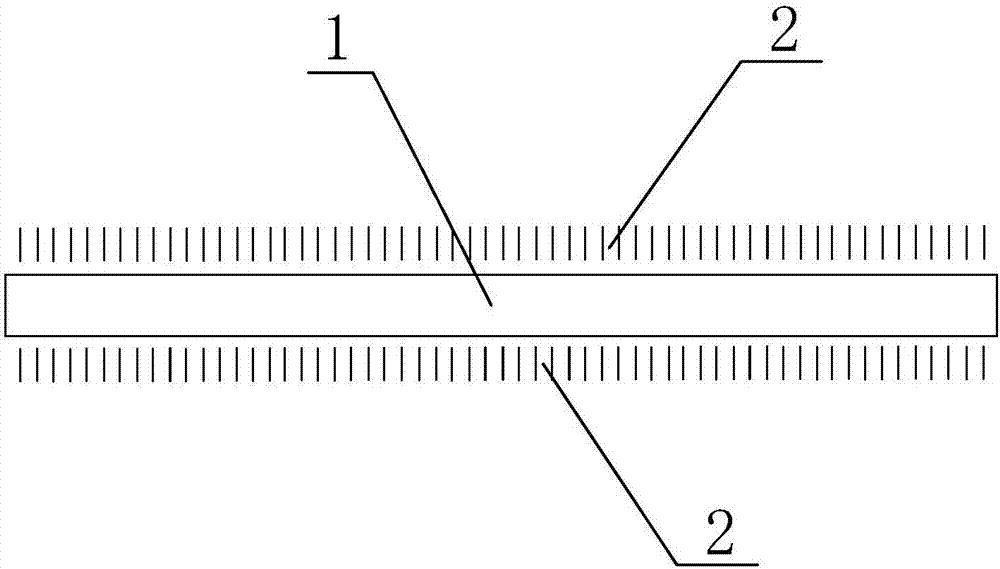

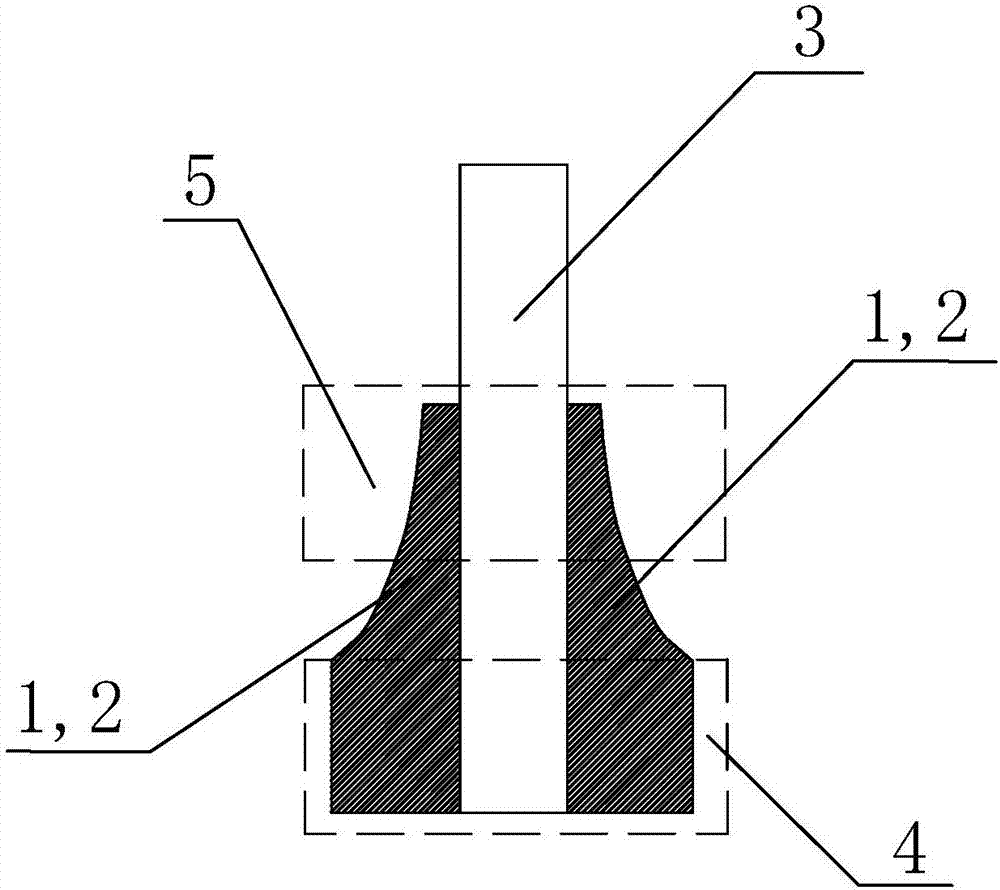

[0035] When making water-based ink 2, water-based ink 2 can be made with the following components: 27% of the proportion of polystyrene butadiene copolymer, 15% of the proportion of terpene resin, 7% of the proportion of tackifying resin, 1% of the proportion anti-aging agent and 50% ethyl acetate. Among them, polystyrene butadiene copolymer is used as the main constituent of the water-based ink 2, terpene resin is used as the viscosity constituent of the water-based ink 2, the tackifying resin is used to increase the viscosity of the water-based ink 2, and the anti-aging agent is used to prevent the water-based ink from 2 Aging and oxidation occur, and ethyl acetate is used as a solvent for dissolving and mixing the above components. When using the various components of the above specific gravity to form water-based ink 2, since the specific gravity of the polystyrene butadiene copolymer is greater than the sum of the specific gravity of the terpene resin and the tackifying r...

no. 2 example

[0037]When making water-based ink 2, water-based ink 2 can be made with the following components: 28% of the proportion of polystyrene butadiene copolymer, 20% of the proportion of terpene resin, 10% of the proportion of tackifying resin, 2% of the proportion anti-aging agent and 40% ethyl acetate. Among them, polystyrene butadiene copolymer is used as the main constituent of the water-based ink 2, terpene resin is used as the viscosity constituent of the water-based ink 2, the tackifying resin is used to increase the viscosity of the water-based ink 2, and the anti-aging agent is used to prevent the water-based ink from 2 Aging and oxidation occur, and ethyl acetate is used as a solvent for dissolving and mixing the above components. When using the various components of the above specific gravity to form water-based ink 2, since the specific gravity of the polystyrene butadiene copolymer is less than the sum of the specific gravity of the terpene resin and the tackifying resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com