Titanium dioxide preparing equipment and oxidation technology process

A technology of titanium dioxide and equipment, which is applied in the field of TiO2 preparation, can solve the problems of fast, difficult and difficult gas phase reaction, and achieve the effects of fast cooling speed, uniform particle size and simple manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

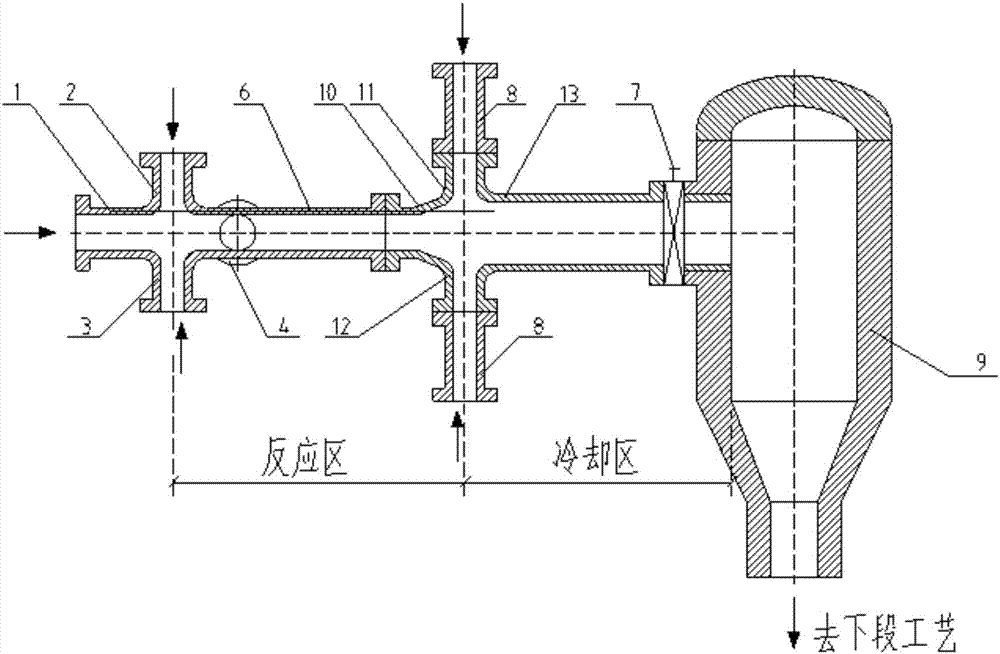

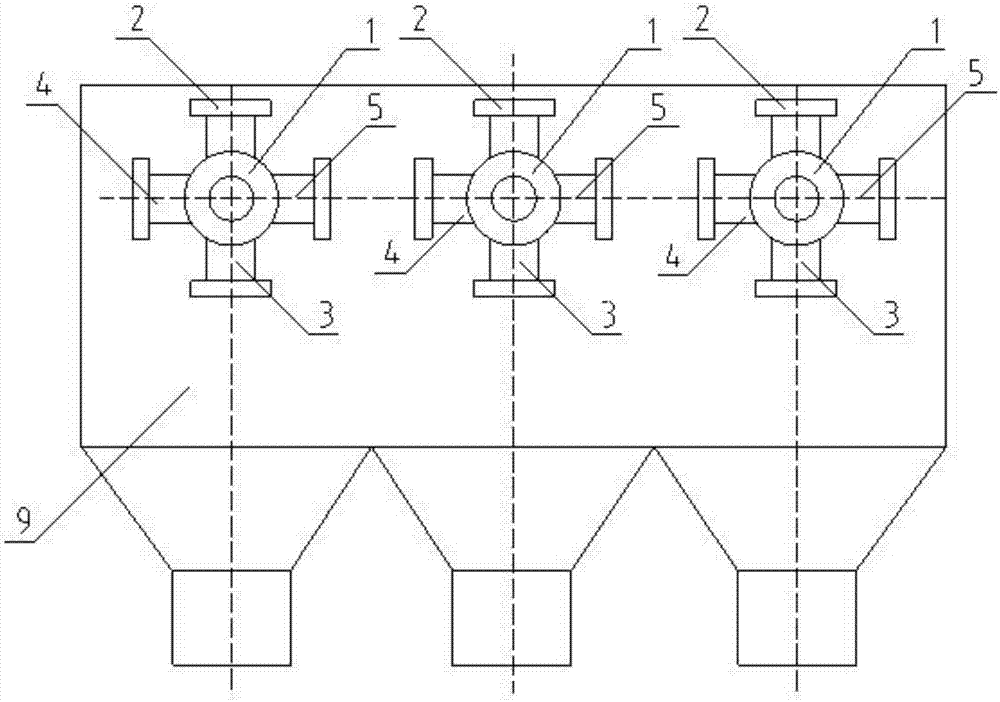

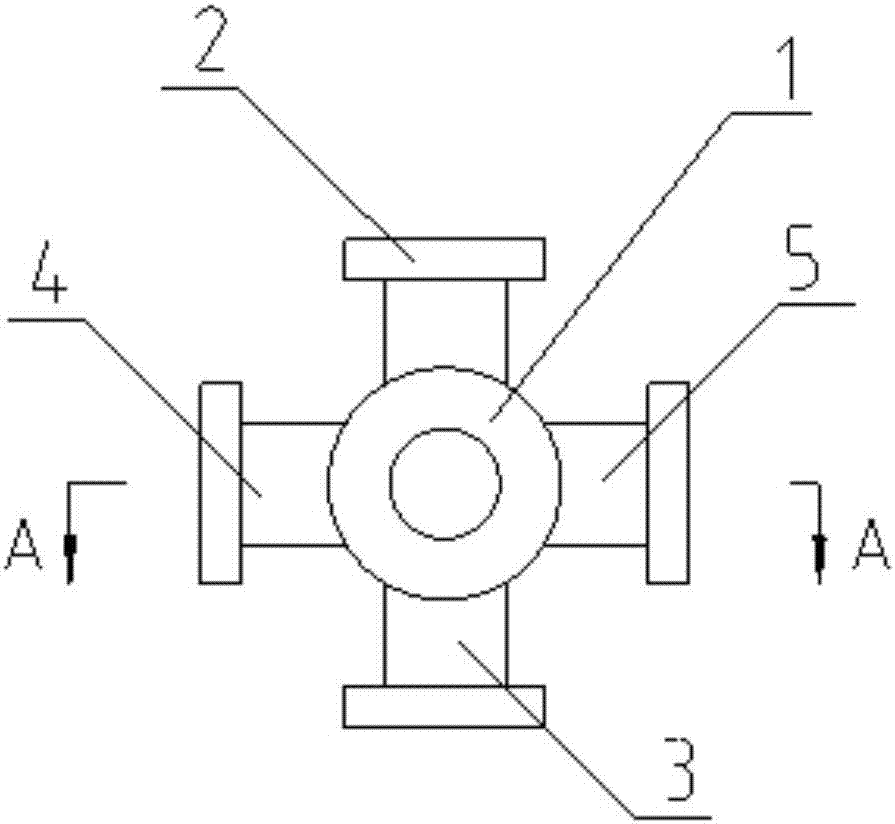

[0031] Such as Figure 1 to Figure 6As shown, the titanium dioxide preparation equipment includes a front-end feed pipe, a counter-spray cooling device and a collecting hopper device, and the front-end feed pipe includes a first feed pipe 1, a second feed pipe 2, and a third feed pipe 3 With the first discharge pipe 6, the spray cooling device includes the fourth feed pipe 10, the fifth feed pipe 11, the sixth feed pipe 12 and the second discharge pipe 13; the first feed pipe 1, the second The feed pipe 2, the third feed pipe 3 and the first discharge pipe 6 communicate, and the first feed pipe 1, the second feed pipe 2, the third feed pipe 3 and the first discharge pipe 6 constitute The shape is cross-shaped; the fourth feed pipe 10, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com