Preparation method and application of poly(1,4-cyclohexylene dimethylene terephthalate) thin film

A technology of cyclohexanedimethanol ester and polyterephthalic acid, which is applied in the direction of flexible covering, packaging, wrapping paper, etc., can solve the problems of low viscosity and no application value, achieve high reaction efficiency and improve the molecular weight of PCT It is difficult to improve and avoid the effect of solvent contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

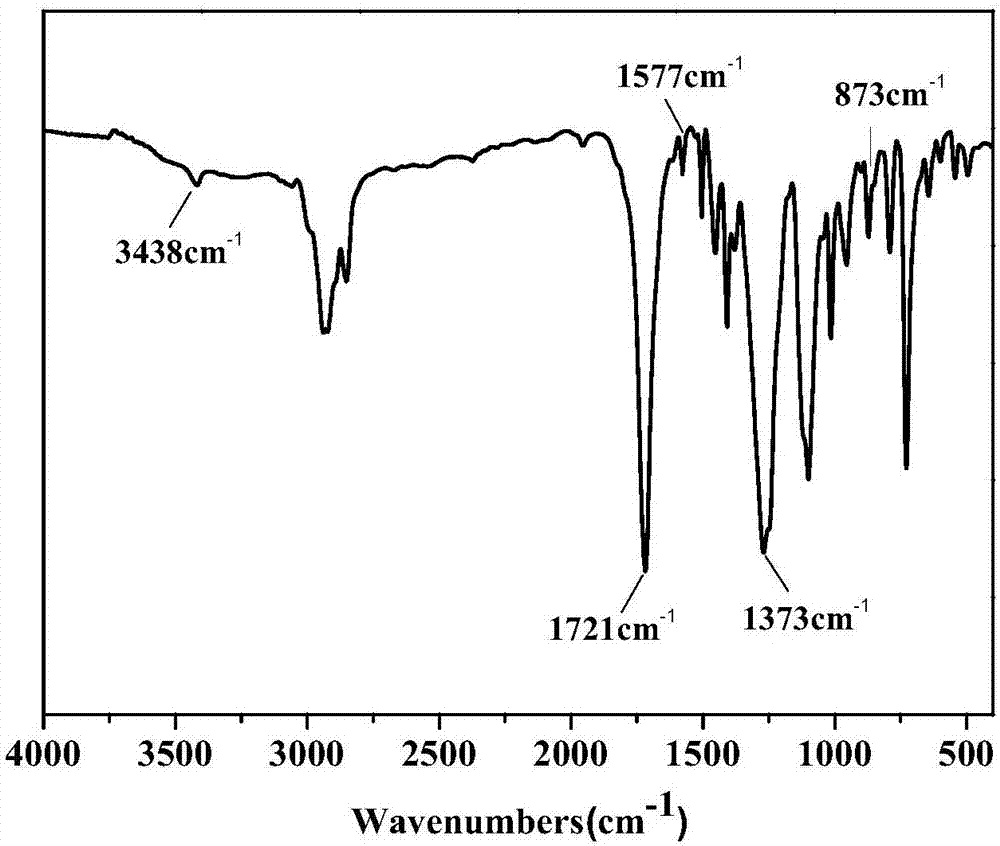

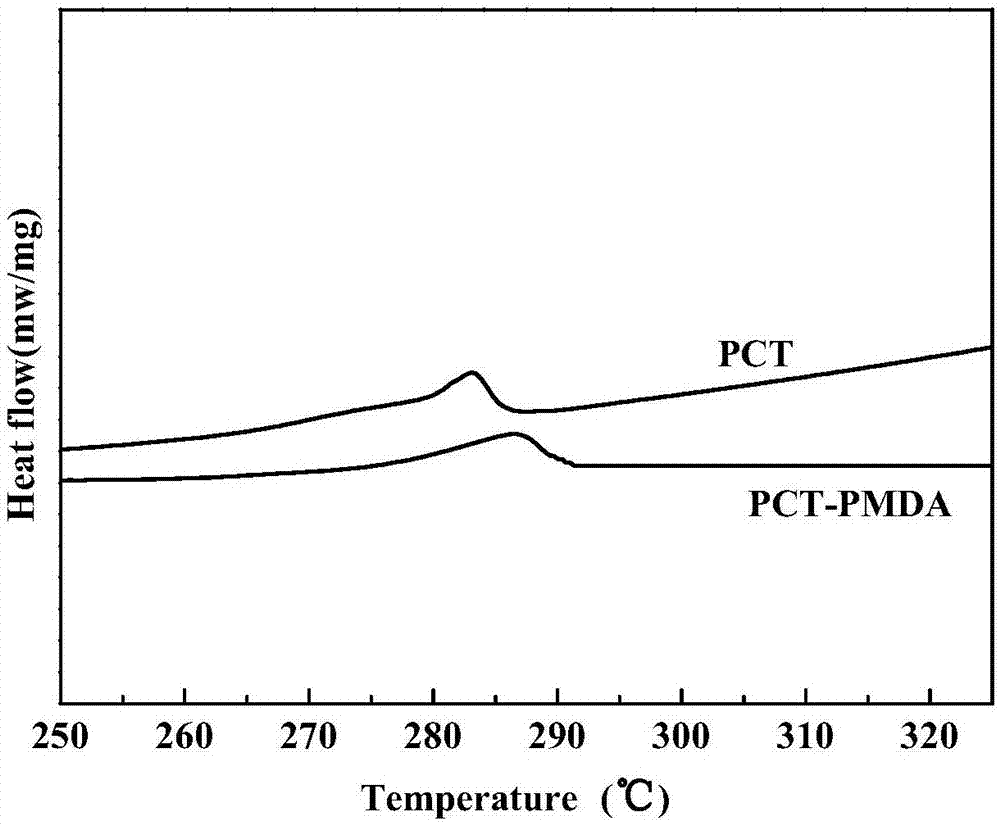

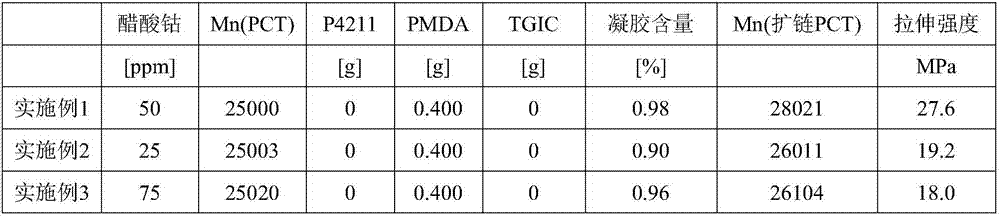

Embodiment 1

[0042] First, 62.51g of waxy 1,4-cyclohexanedimethanol was melted in a water bath at 70°C, and added to a 250ml four-necked flask. Add 60.10 g of terephthalic acid (PTA) into the four-necked flask, add 0.012 g of germanium dioxide and 0.012 g of antimony ethylene glycol, stir evenly, and then turn on the heating device. React at 235°C under normal pressure for about 4 hours until the system becomes transparent and the esterification reaction is complete. 0.012g of tetrabutyl titanate and 0.006g of cobalt acetate were dissolved in 1mL of ethylene glycol and added to the system. Raise the temperature to 270°C and evacuate to 2000Pa, react for 30 minutes; then raise the temperature to 290°C, and evacuate to 80Pa, react until the torque of the agitator no longer changes, stop the reaction, and pour the produced product into water while it is hot to quench. The above product was dissolved in 1,1,2,2-tetrachloroethane at 110°C, and purified by settling with acetone to obtain polyme...

Embodiment 2

[0047] The difference between this embodiment and Example 1 is that the addition of cobalt acetate is 0.003g, and others are the same as in Example 1, and the PCT number-average molecular weight obtained is 25003, the extended chain PCT-PMDA number-average molecular weight is 26011, and the gel content is 0.90%.

Embodiment 3

[0049] The difference between this embodiment and Example 1 is that the addition of cobalt acetate is 0.009g, and others are the same as Example 1, and the PCT number-average molecular weight obtained is 25020, the extended chain PCT-PMDA number-average molecular weight is 26104, and the gel content is 0.96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com