Metal cotton-based lithium sulfur battery anode material and preparation method thereof

A technology for lithium-sulfur batteries and positive electrode materials, which is applied to battery electrodes, lithium batteries, and non-aqueous electrolyte battery electrodes. It can solve the problems of non-conductivity, achieve light weight, ease volume expansion, and good charge-discharge cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

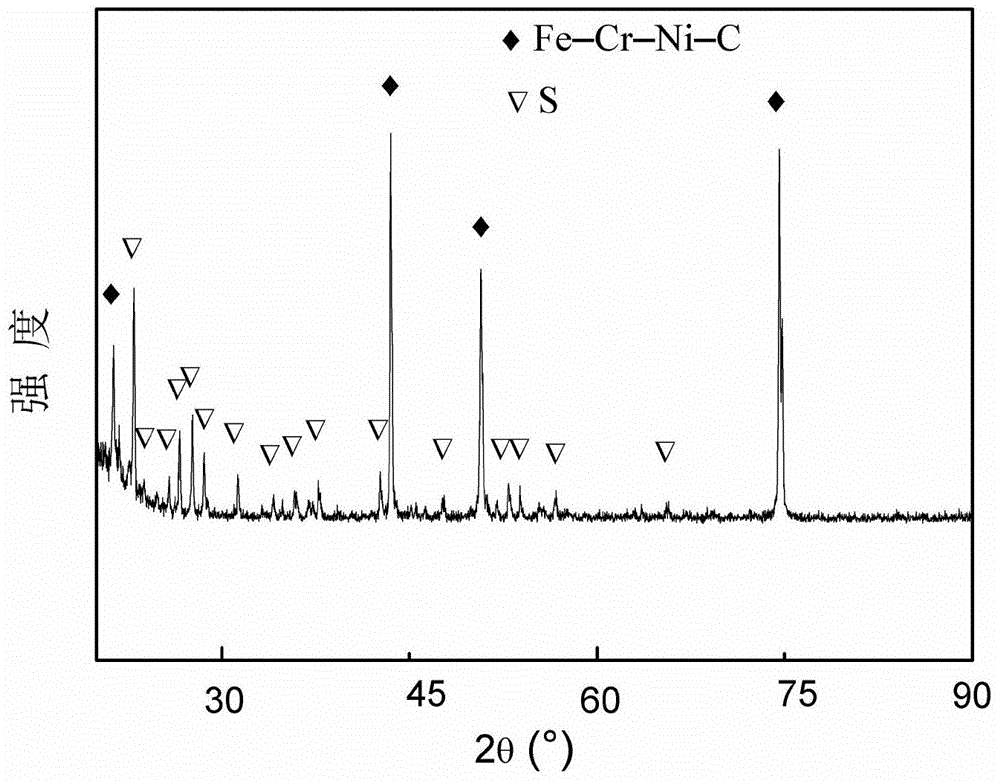

[0033] Preparation of sulfur composite metal wool integrated positive electrode: Cut a 1mm thick metal wool sheet into a disc with a diameter of 13mm, clean it with ultrasonic waves in a 1mol / L HCl solution for 15 minutes, and then use 1mol / L NaHCO 3 Ultrasonic cleaning in the solution for 15 minutes, ultrasonic cleaning in deionized water for 15 minutes, the ultrasonic power is 100W, the cleaned metal wool is dried at 60℃ for 3 hours, and then used; weigh the quality of the cleaned and dried metal wool with an electronic balance M1, weigh 15mg of elemental sulfur, evenly cover the elemental sulfur on the metal wool, place it in a vacuum drying oven, and set the vacuum drying oven parameters to 120°C for 3h to make the elemental sulfur enter the pores of the metal wool. The cathode material for lithium-sulfur battery of sulfur composite metal wool can be obtained. Weigh the mass M2 of the sulfur-added metal wool with an electronic balance again. The difference between the mass a...

Embodiment 2

[0036] The preparation process of the sulfur composite metal wool integrated positive electrode is the same as in Example 1, and the lithium-sulfur battery is assembled in the same manner as in Example 1. The content of elemental sulfur in Example 2 is 1 mg. After the battery is assembled, the battery is left to stand for 24 hours, and the cyclic voltammetry test is performed on this embodiment using the Shanghai Chenhua electrochemical workstation. The test voltage is 1 to 3V and the scanning rate is 0.1mV / S. Corresponds to the attached Image 6 The cyclic voltammetry curve in the graph.

Embodiment 3

[0038] The preparation process of the sulfur composite metal wool integrated positive electrode is the same as in Example 1, and the lithium-sulfur battery is assembled in the same manner as in Example 1. The content of elemental sulfur in Example 3 is 0.45 mg. Use the Newwell battery test system to test the rate stability performance of the assembled battery. The test temperature is room temperature, the charging and discharging voltage is 1-3V relative to Li / Li+, and the charging and discharging ratios are 0.1C, 0.2C, 0.5C, 1C, 2C, 5C, and 0.1C. Corresponds to the attached Figure 7 The magnification performance curve in.

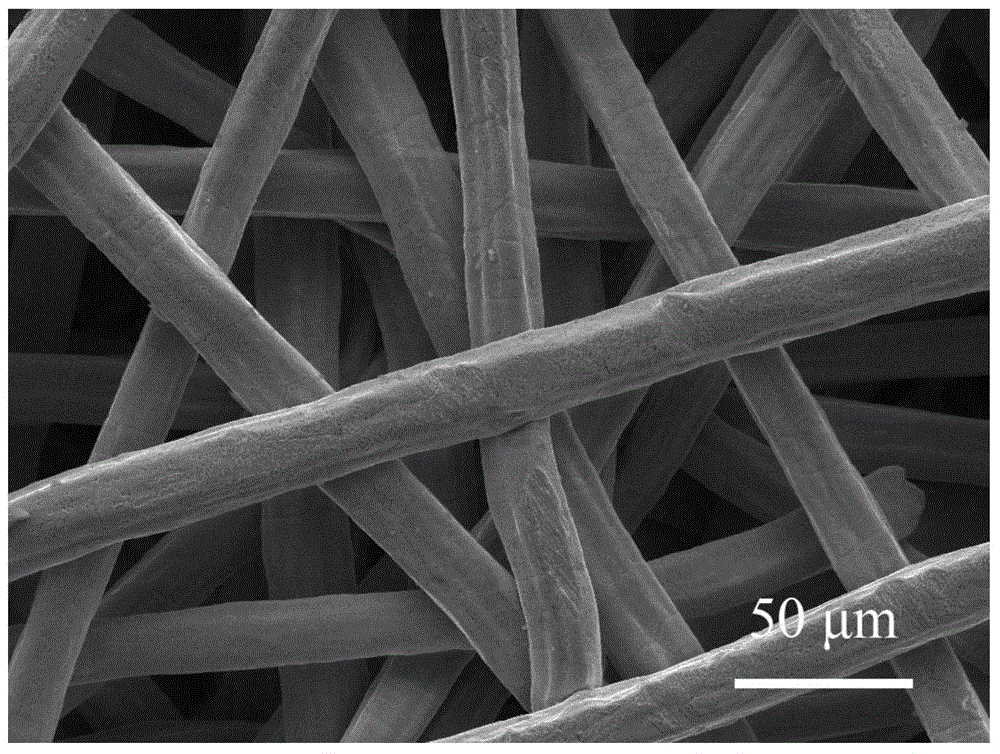

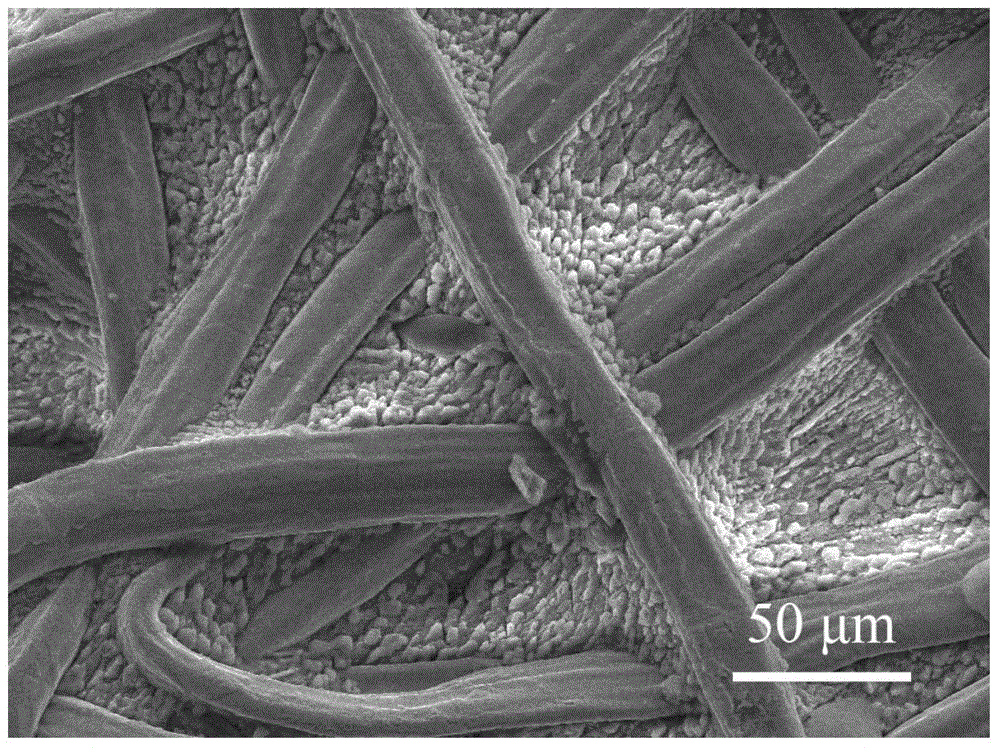

[0039] From figure 1 It can be seen that the metal wool material is a porous material, and its composition is a porous material formed by many stainless steel wires interlaced together. It can be seen from the figure that the pore size of the material is not uniform, and the pore size is about 10~200μm, the porosity is higher, reaching more than 50%.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com