Copper-based low-temperature reversible thermochromic material and preparation method thereof

A thermochromic material and low temperature technology, applied in the field of materials, can solve the problems of irreversible discoloration process and high discoloration temperature, and achieve the effects of simple and mature preparation method, low discoloration temperature and short discoloration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

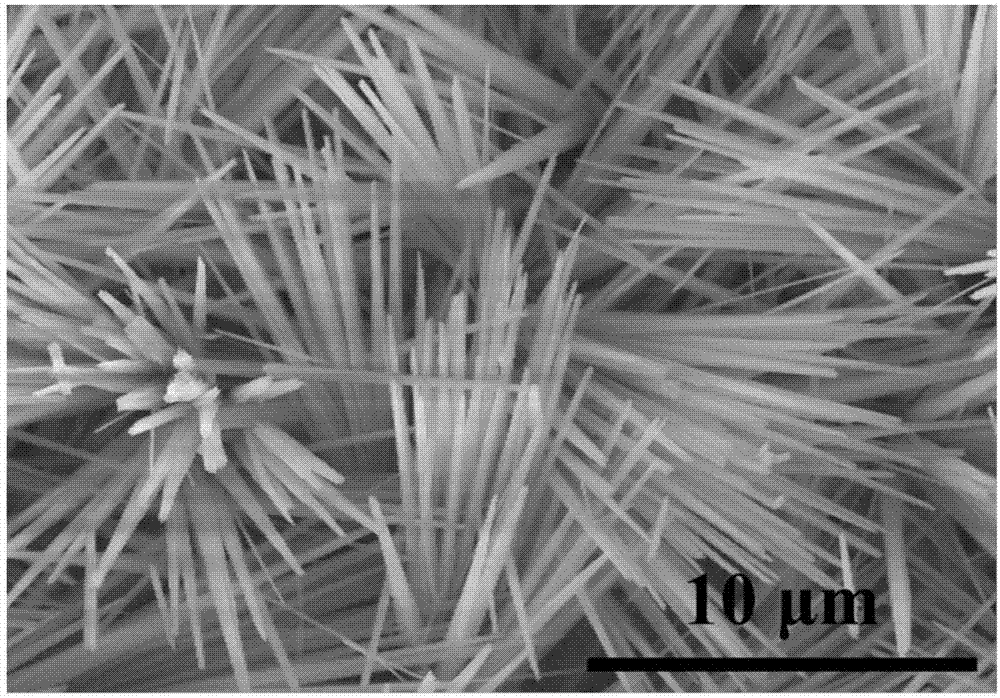

[0031] Cu(OH) 2 The preparation method of the nanowire array includes the following steps:

[0032] (1) The Cu sheet with a purity greater than 99.9% and the Ti sheet with a purity greater than 99.7% were ultrasonicated in acetone, absolute ethanol and deionized water for 10 minutes respectively to remove oil stains and oxides on the surface, and dried in an oven for use;

[0033] (2) The high-purity Cu sheet after cleaning and drying was used as the anode, the high-purity Ti sheet after cleaning and drying was used as the cathode, and the anodic oxidation reaction was performed in a 2mol / LKOH aqueous solution for 10 minutes, and the current density was 2.5mA / cm 2 , the reaction temperature is 10 °C to obtain Cu(OH) 2 array of nanowires.

Embodiment 2

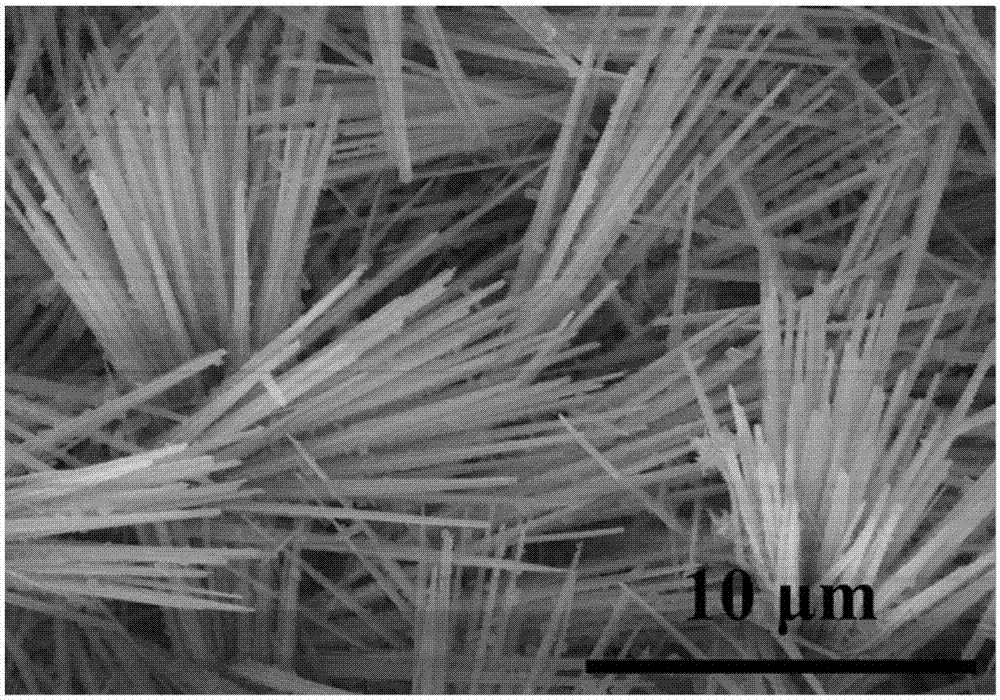

[0035] A preparation method of a copper-based low-temperature reversible thermochromic material, comprising the following steps:

[0036] (1) The Cu sheet with a purity greater than 99.9% and the Ti sheet with a purity greater than 99.7% were ultrasonicated in acetone, absolute ethanol and deionized water for 10 minutes respectively to remove oil stains and oxides on the surface, and dried in an oven for use;

[0037] (2) The high-purity Cu sheet after cleaning and drying was used as the anode, the high-purity Ti sheet after cleaning and drying was used as the cathode, and the anodic oxidation reaction was performed in a 2mol / LKOH aqueous solution for 10 minutes, and the current density was 2.5mA / cm 2 , the reaction temperature is 10 °C to obtain Cu(OH) 2 array of nanowires;

[0038] (3) Cu(OH) obtained in step (2) 2 The nanowire array was placed in 50 mmol / L 1,3,5-benzenetricarboxylic acid in anhydrous ethanol solution, soaked for 5 min, the reaction temperature was 25 °C, ...

Embodiment 3

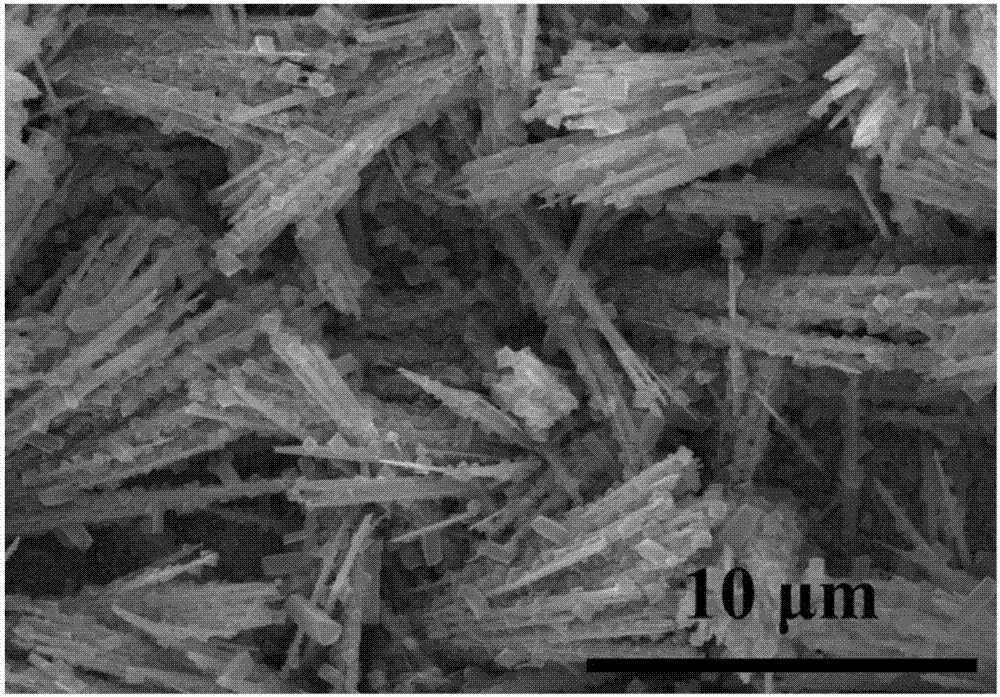

[0040] A preparation method of a copper-based low-temperature reversible thermochromic material, comprising the following steps:

[0041] (1) The Cu sheet with a purity greater than 99.9% and the Ti sheet with a purity greater than 99.7% were ultrasonicated in acetone, absolute ethanol and deionized water for 10 minutes respectively to remove oil stains and oxides on the surface, and dried in an oven for use;

[0042] (2) The high-purity Cu sheet after cleaning and drying was used as the anode, the high-purity Ti sheet after cleaning and drying was used as the cathode, and the anodic oxidation reaction was performed in a 2mol / LKOH aqueous solution for 10 minutes, and the current density was 2.5mA / cm 2 , the reaction temperature is 10 °C to obtain Cu(OH) 2 array of nanowires;

[0043] (3) Cu(OH) obtained in step (2) 2 The nanowire array was placed in 50 mmol / L 1,3,5-benzenetricarboxylic acid in anhydrous ethanol solution, soaked for 10 min, the reaction temperature was 25 °C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com