An intelligent seaming machine for asphalt pavement

A technology of asphalt pavement and seaming machine, which is applied in the direction of roads, roads, road repairs, etc. It can solve the problems of heavy smoke pollution, unfavorable crack repair, and low work efficiency, so as to reduce labor input, reduce maintenance costs, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The intelligent asphalt pavement seaming machine provided by the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

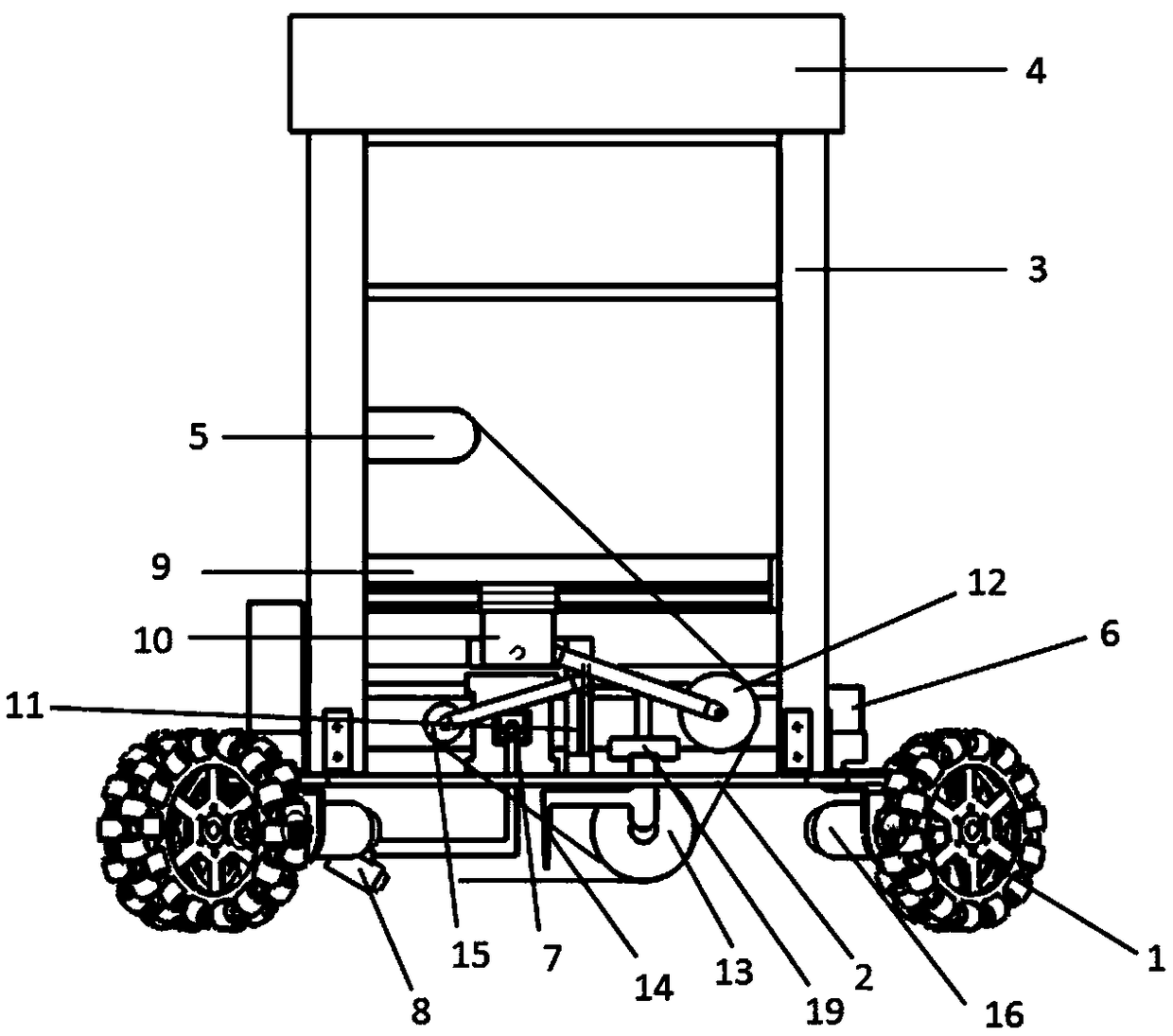

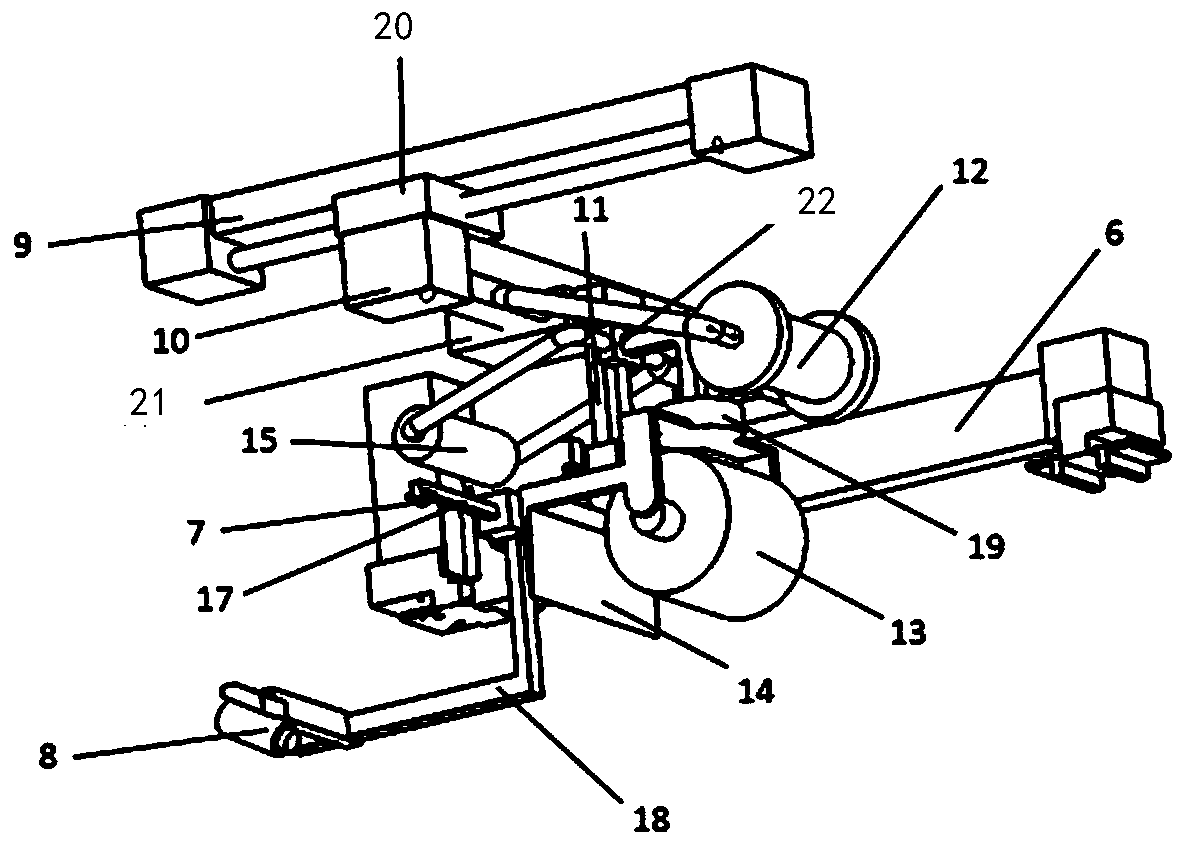

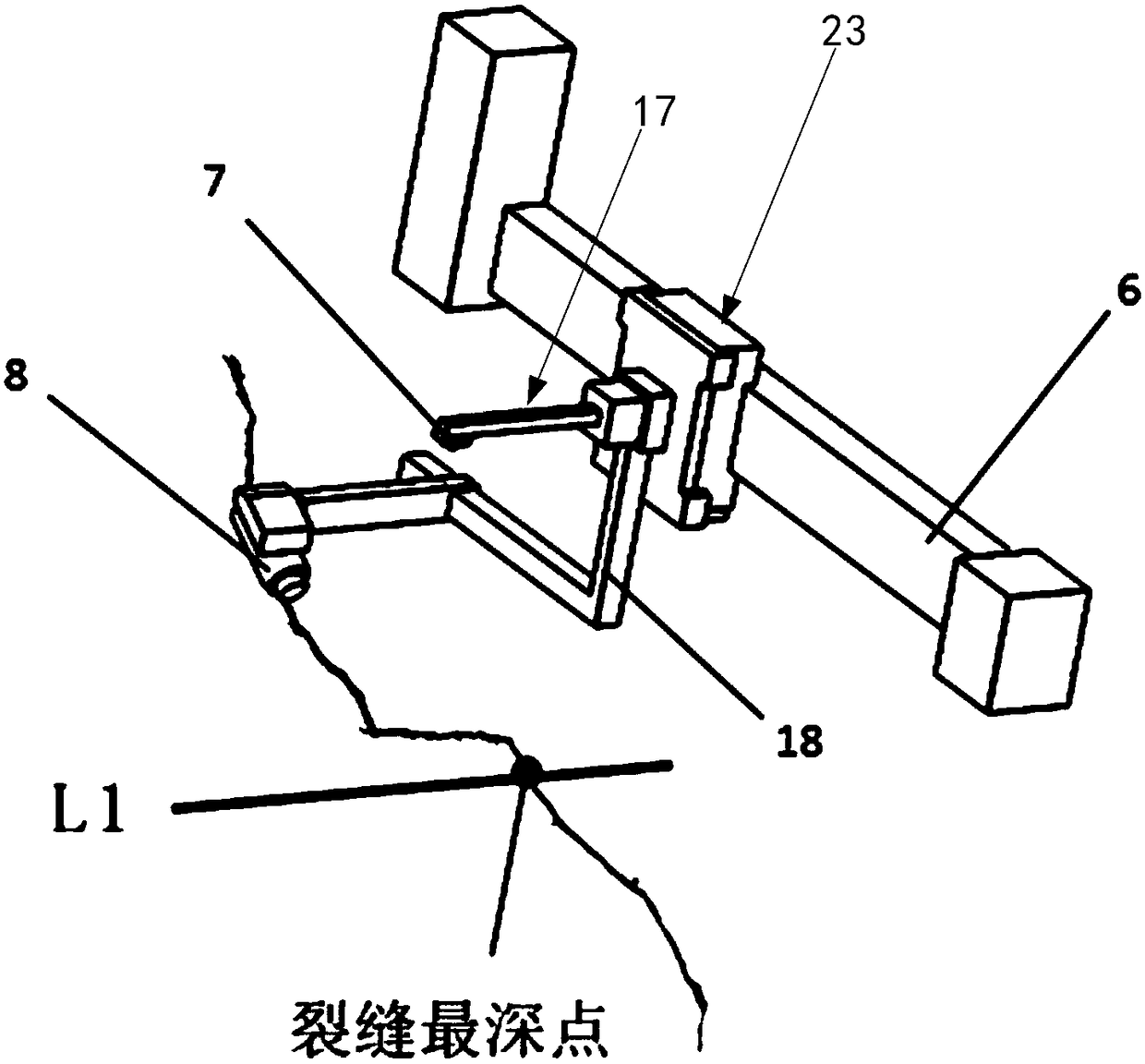

[0027] The invention provides an intelligent seaming machine for asphalt pavement, which can realize the functions of identifying cracks in the asphalt pavement and pasting joint glue on the cracks for repair. Such as figure 1 As shown, the intelligent asphalt pavement seaming machine includes an omnidirectional wheel 1, an omnidirectional wheel drive motor 16, a chassis 2, a vehicle frame 3, an industrial computer 4, a storage roller 5, a slide table D6, a camera 7, and a laser head 8. Slide table A9, slide table B10, slide table C11, guide wheel 12, rolling wheel 13, blade 14 and roll film wheel 15. The chassis 2 is a square aluminum alloy plate with a square hole in the middle, and the chassis 2 is parallel to the ground in a normal working state. Four omnidirectional wheel drive motors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com