Soil auger

A technology of earth drill and drill bit, which is applied in the direction of sampling device, etc., which can solve the problems of simple connection between drill body and drill bit, inconvenient carrying and operation, and oversized motor earth drill, and achieves low price, time-saving and high-efficiency sampling, Effects that enhance functionality and usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

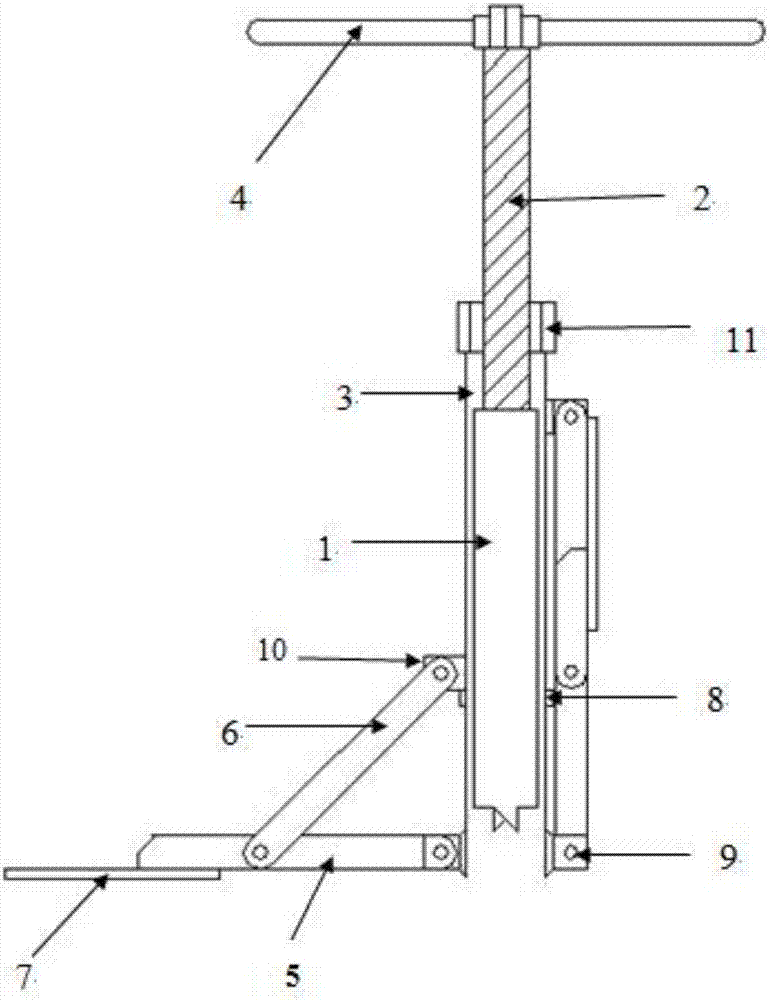

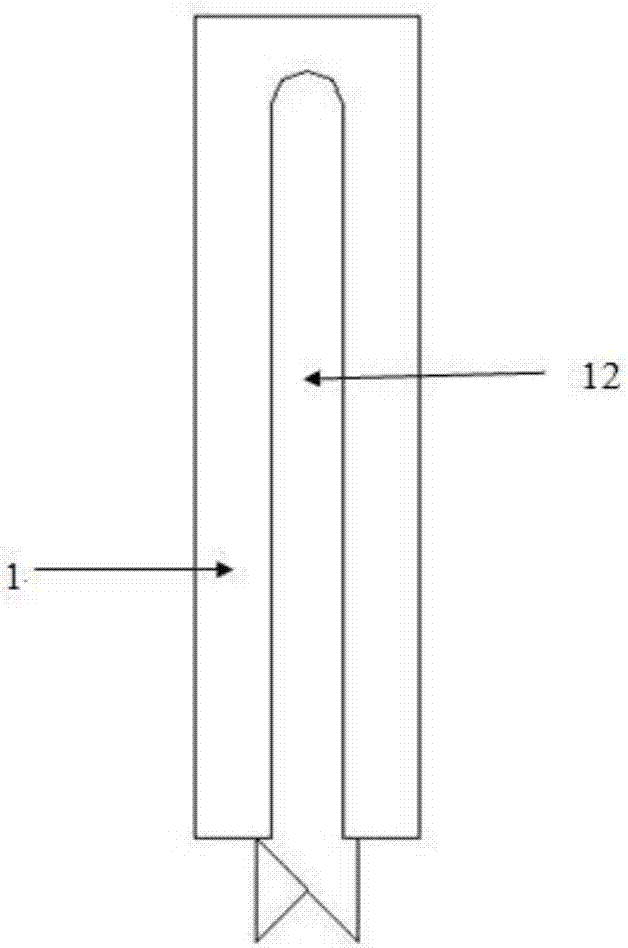

[0036] Such as figure 1 As shown, an earth drill includes a drill bit 1, a screw rod 2, a drill barrel 3, a handle 4, a tie rod 5, a diagonal tie rod 6, a pedal 7, a positioning block 8, a support 9, a slider 10, a nut 11, and an excavation groove. 12. The upper end of the screw 2 is connected to the handle 4, the lower end of the screw 2 is connected to the upper end of the drill bit 1, the screw 2 is provided with an external thread matching the internal thread of the nut 11, and the nut 11 is threaded on the screw 2.

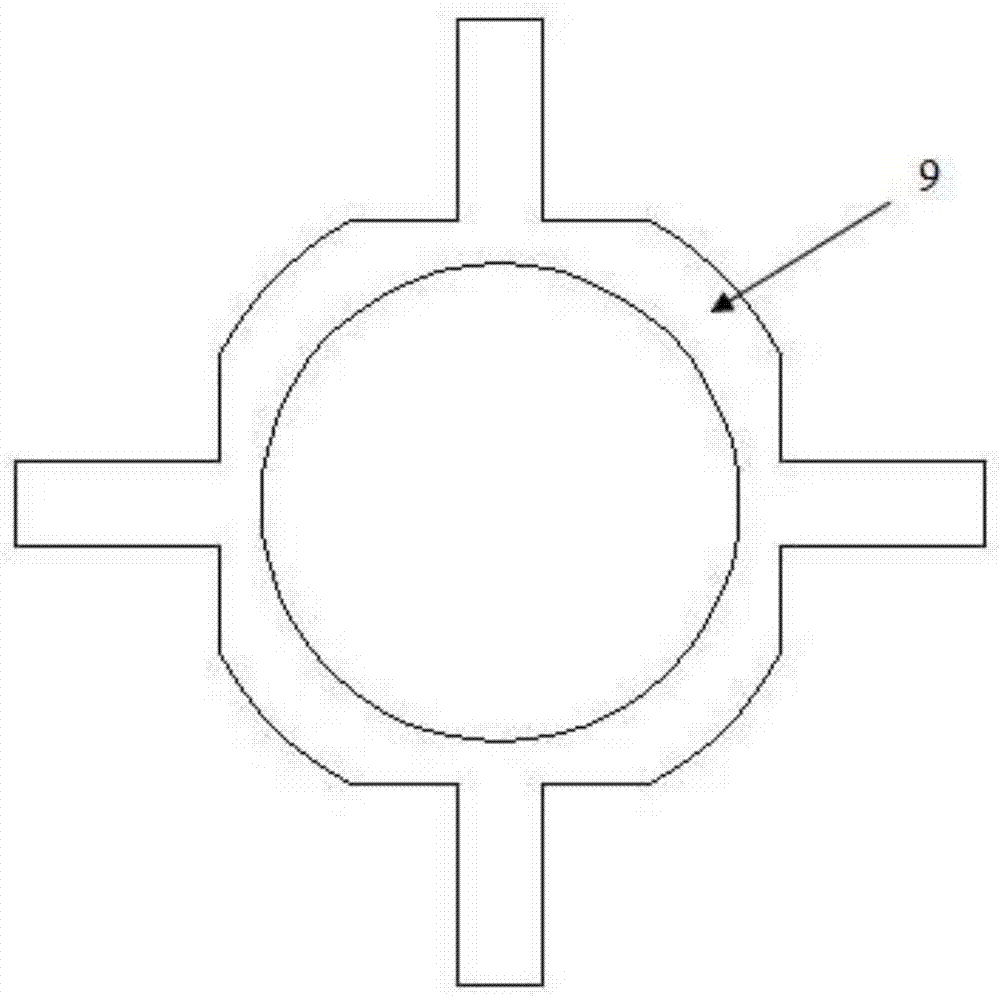

[0037] The upper end of the drill tube 3 is connected with the nut 11, the lower end of the drill tube 3 is welded with a support 9, and the drill bit 1 is placed in the drill tube 3.

[0038] Such as figure 1 As shown, one end of the tie rod 5 is welded and fixed on the support 9, and the other end of the tie rod 5 is connected to the pedal 7; one end of the tie rod 6 is connected to the middle position of the tie rod 5, and the other end of the tie rod 6 p...

Embodiment 2

[0047] In this embodiment, the screw rod and the drill bit are pin-connected with a detachable device, and the drill bit can be disassembled and replaced during operation.

[0048] Such as figure 1 As shown, an earth drill includes a drill bit 1, a screw rod 2, a drill barrel 3, a handle 4, a tie rod 5, a diagonal tie rod 6, a pedal 7, a positioning block 8, a support 9, a slider 10, a nut 11, and an excavation groove. 12. The upper end of the screw 2 is connected to the handle 4, the lower end of the screw 2 is connected to the upper end of the drill bit 1, the screw 2 is provided with an external thread matching the internal thread of the nut 11, and the nut 11 is threaded on the screw 2.

[0049] The upper end of the drill tube 3 is connected with the nut 11, the lower end of the drill tube 3 is welded with a support 9, and the drill bit 1 is placed in the drill tube 3.

[0050] Such as figure 1 As shown, one end of the tie rod 5 is welded and fixed on the support 9, and ...

Embodiment 3

[0059] In this embodiment, the drill barrel and the nut are connected together in a detachable manner, and the direction of the drill body can be disassembled and replaced during operations.

[0060] Such as figure 1 As shown, an earth drill includes a drill bit 1, a screw rod 2, a drill barrel 3, a handle 4, a tie rod 5, a diagonal tie rod 6, a pedal 7, a positioning block 8, a support 9, a slider 10, a nut 11, and an excavation groove. 12; The upper end of the screw rod 2 is connected to the handle 4, and the lower end of the screw rod 2 is connected to the upper end of the drill bit 1; the drill bit 1 is placed in the drill barrel 3.

[0061] The upper end nut 11 of the drill tube 3 is connected in a detachable manner, the lower end of the drill tube 3 is welded with a support 9, and the drill bit 1 is placed in the drill tube 3 .

[0062] Such as figure 1 As shown, one end of the tie rod 5 is welded and fixed on the support 9, and the other end of the tie rod 5 is connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com