Fiber reinforced composite material parameter identifying method based on laser nondestructive scanning, and device

A fiber-reinforced, composite material technology, used in measuring devices, analyzing materials, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. The effect of saving raw materials, reducing workload, and reducing experimental errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] 1. Tester hardware structure design

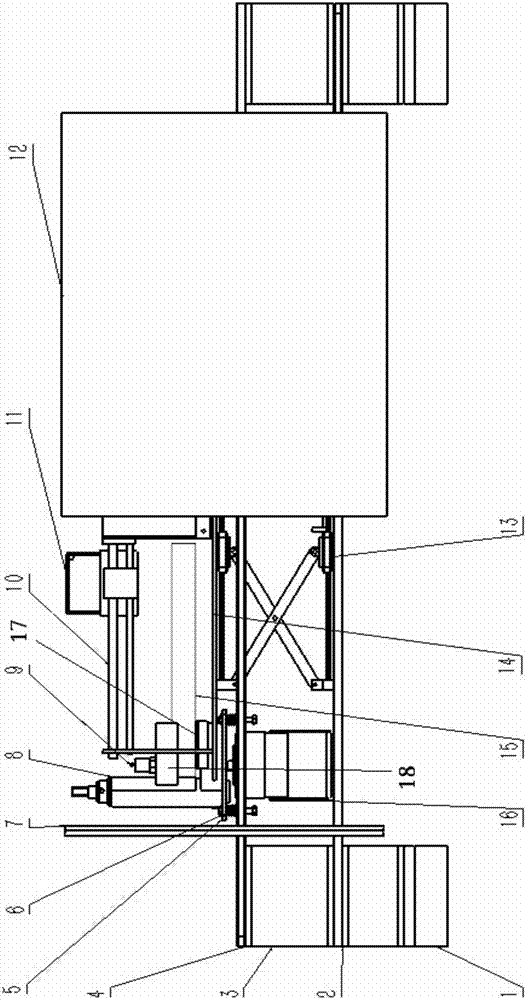

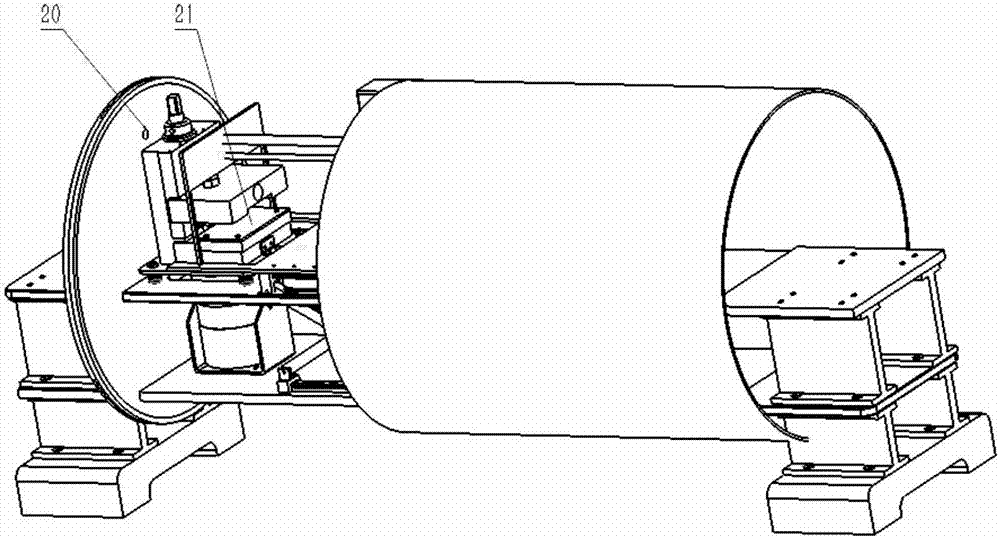

[0026] As shown in the figure, the device of the present invention is mainly composed of a compound working platform, a lifting platform, a clamping mechanism, an excitation device, a laser scanning vibration measurement system and a vacuum device;

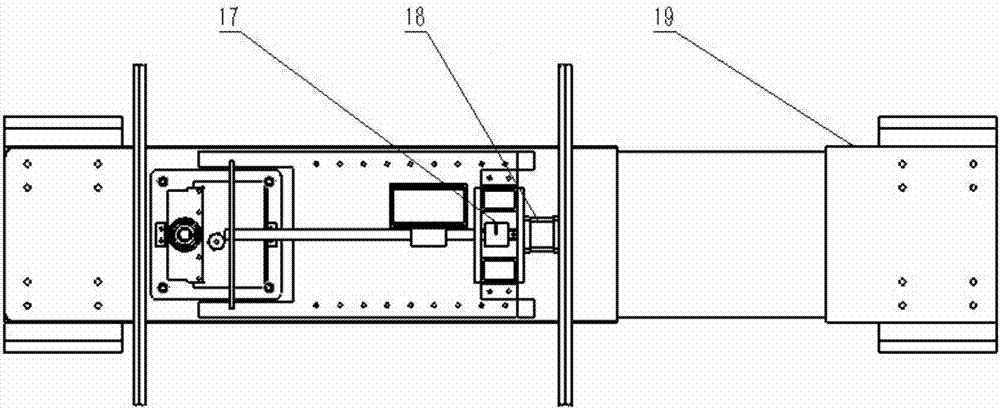

[0027] The compound working platform includes the first working platform 4 and the second working platform 2, the two platforms are connected by the "I"-shaped support steel 3, and the bottom is supported by the base 1; the clamping mechanism 8 is used to fix and monitor the composite beam specimen to be tested 15, including the reference platform 17 and the briquetting block 18 on its top, the briquetting block is driven down by bolts to fix the composite beam specimen to be tested;

[0028] Two circular hole structures are set on the upper surface of the reference platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com