A kind of multi-level doped PBTE-based thermoelectric material and preparation method thereof

A technology of thermoelectric materials and multi-energy levels, which is applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problems of reducing bipolar effect, mobility decline, and no experimental results, etc., to achieve high Thermoelectric Figure of Merit, Effect of Improving Thermoelectric Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A multi-level doped PbTe-based thermoelectric material with a molecular formula of In x Pb 1-x Te 0.996 I 0.004 , where 00.00125 Pb 0.99875 Te 0.996 I 0.004 ,In 0.0025 Pb 0.9975 Te 0.996 I 0.004 ,In 0.0035 Pb 0.9965 Te 0.996 I 0.004 and In 0.005 Pb 0.995 Te 0.996 I 0.004 .

[0041] Step S1: Vacuum-seal In, Pb, Te, and I in a quartz tube according to the ratio, raise the temperature to 1000° C. at a heating rate of 200° C. / h, and hold the temperature for 6 hours.

[0042] Step S2: Then lower the temperature to 600° C. at a rate of 200° C. / h, anneal at this temperature for 50 hours, and finally lower the temperature to room temperature at a rate of 200° C. / h.

[0043] Step S3: Clean and pulverize the obtained ingot in a glove box, and heat press the powder at 600° C. and 80 MPa for 2 minutes with a DC hot press.

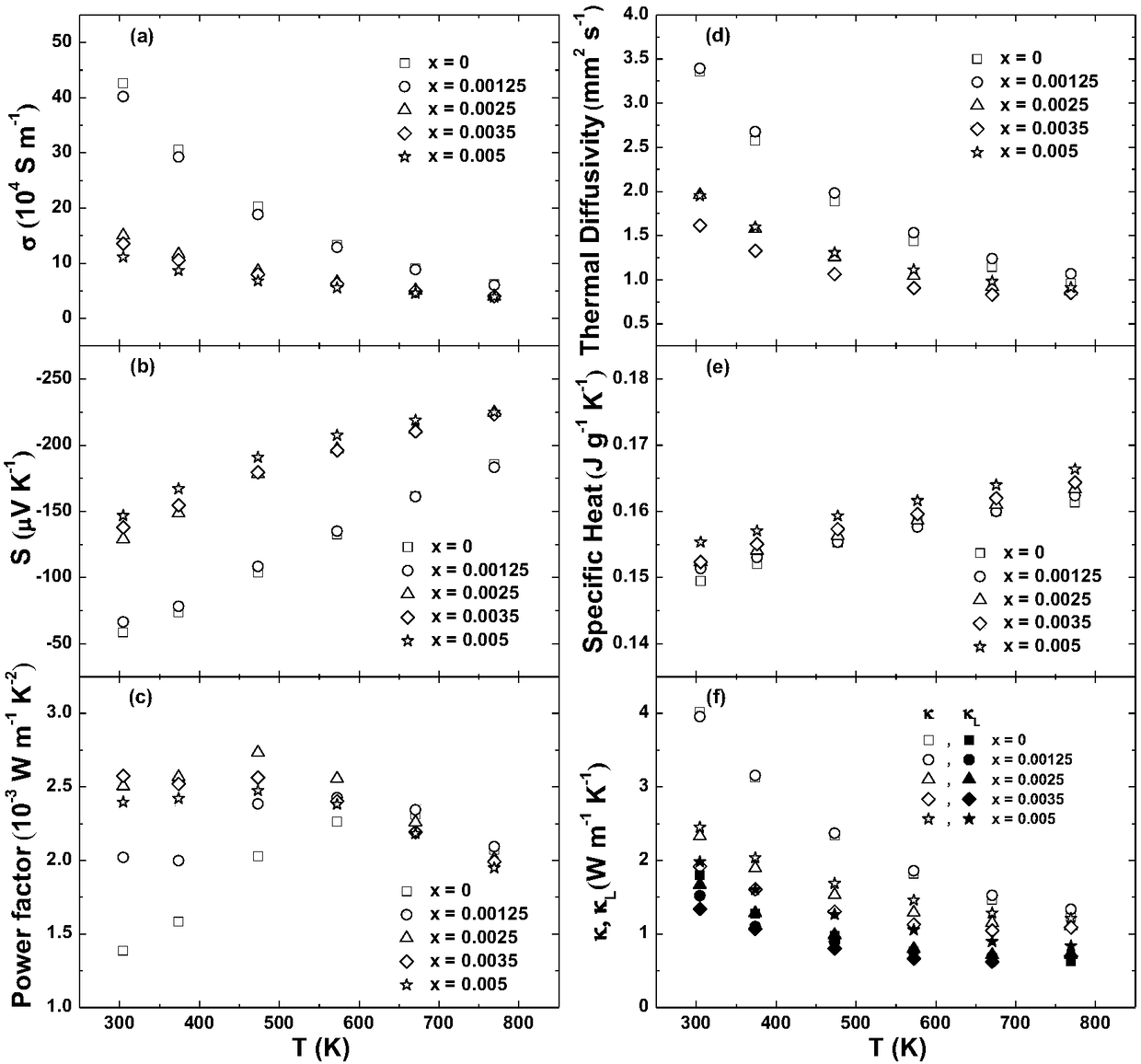

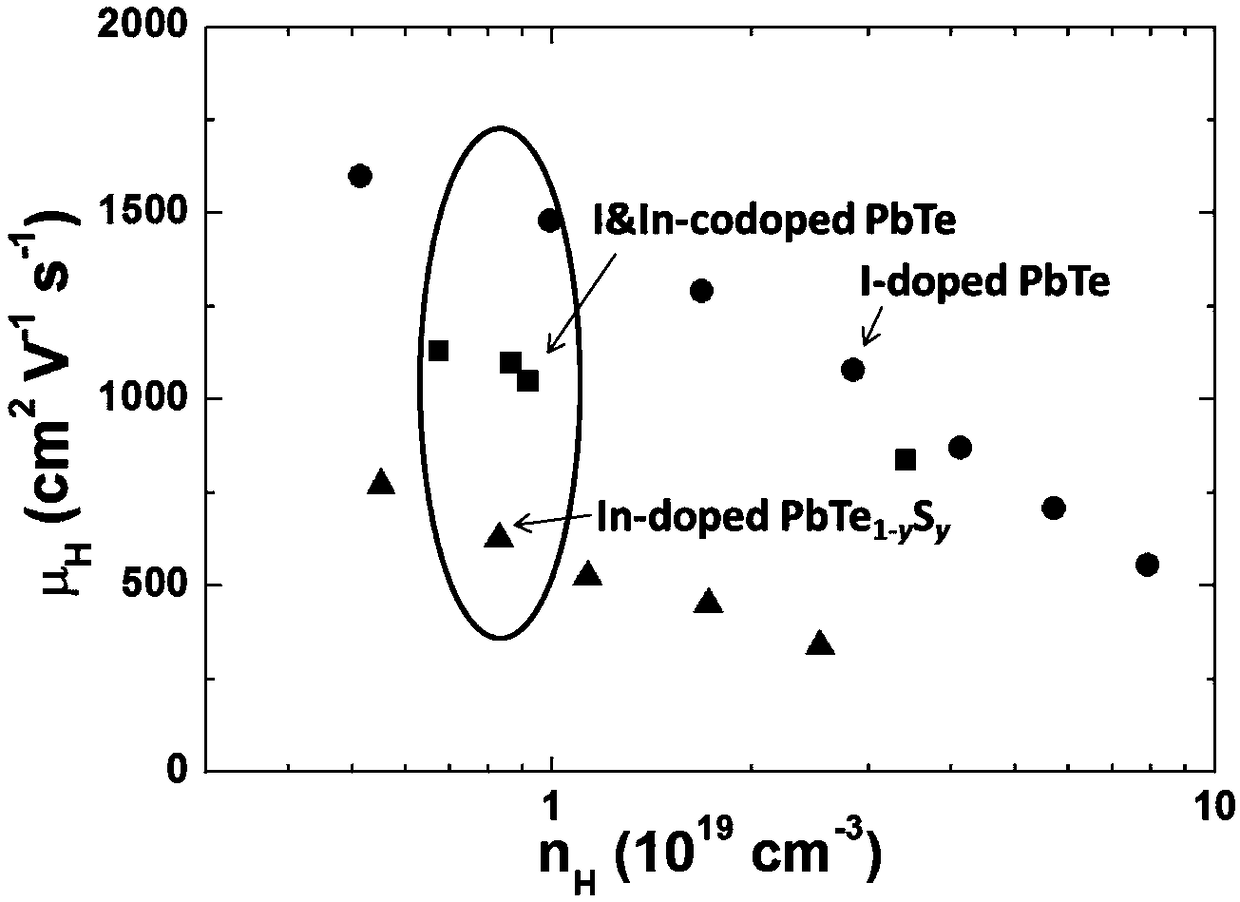

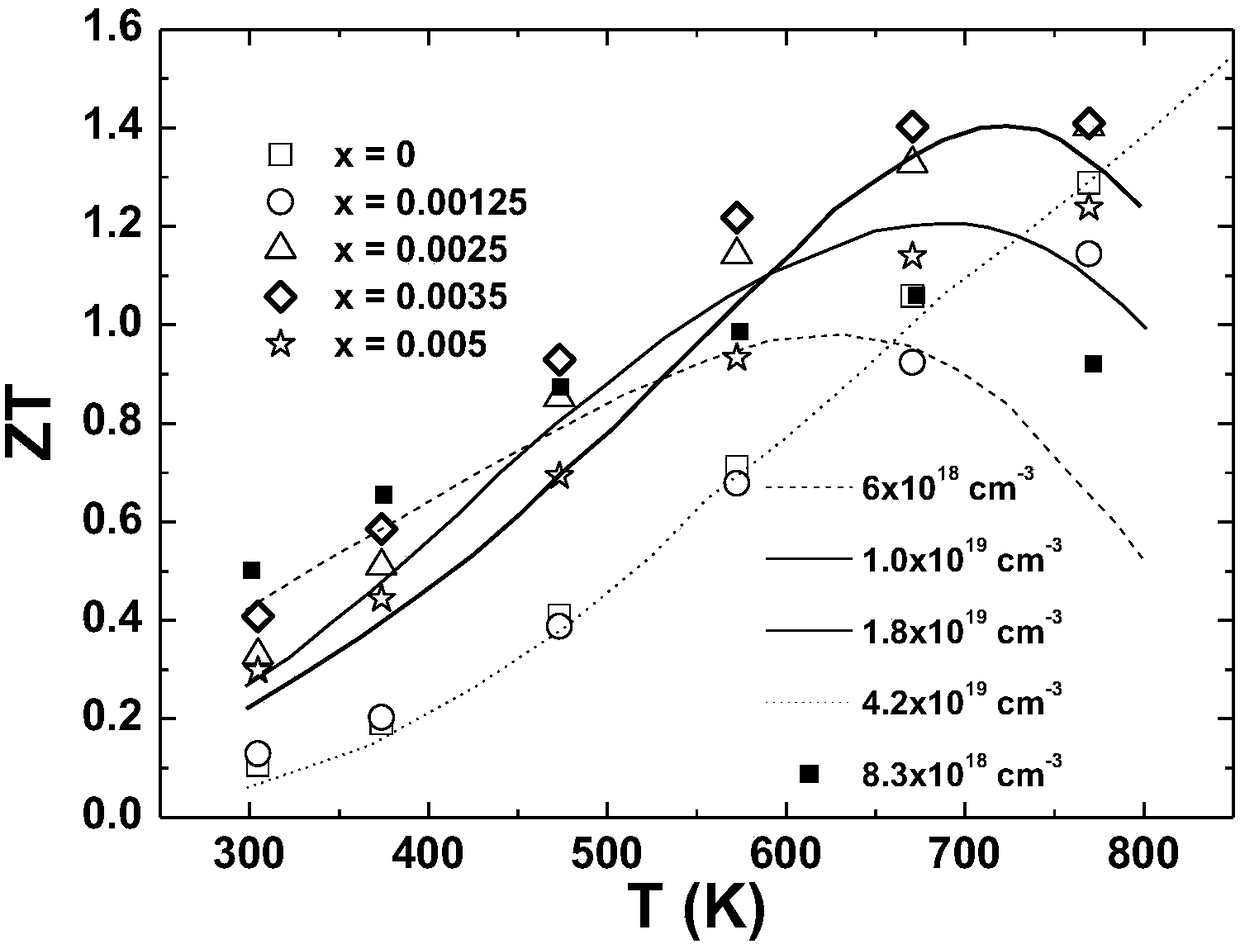

[0044] Then the materials prepared above were tested and analyzed. figure 1 Doping In for multiple energy levels x Pb 1-x Te 0.996 I 0.0...

Embodiment 2

[0050] Multi-level doping of PbTe-based thermoelectric material In with different A elements x Pb 1-x Te 1-y A y , wherein, A is Cl, Br, I, Ga, Al; 0<X≤0.02, 0<Y≤0.03, the preparation method is the same as in Example 1, and its performance analysis is carried out.

[0051] Table 1 shows the data of thermoelectric figure of merit Z and thermoelectric efficiency (low temperature end 50°C) at 500°C for the examples using deep-level impurity In and different shallow-level impurities A and the corresponding comparative examples.

[0052] Table 1

[0053]

[0054] It can be seen from the data in Table 1 that the thermoelectric materials obtained by co-doping with deep-level impurity In and different shallow-level impurities A have high thermoelectric figure of merit compared with the comparative examples, which improves the thermoelectric efficiency of the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com