A kind of cereal-based edible tableware and its manufacturing method

A production method and tableware technology, applied in application, bakery, food science, etc., can solve the problems of high processing cost, waste of raw materials, and long cycle of material degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

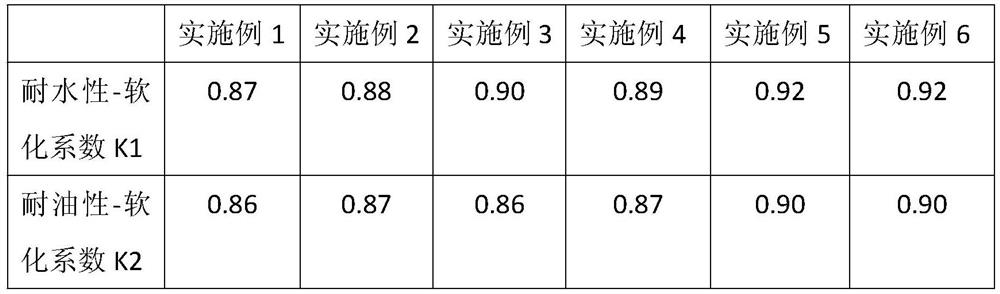

Examples

Embodiment 1

[0016] 60 parts of whole wheat flour, 20 parts of sorghum flour, 15 parts of rice flour, and 5 parts of millet flour were subjected to microwave-assisted treatment and roasting and pre-cooking treatment. The power of microwave-assisted treatment was 500W, the time was 120S, and the power of roasting and pre-cooking treatment was 900W. The time is 10 minutes; after the microwave-assisted treatment and roasting and pre-cooking treatment, 3 parts of grain flour and butter, 5 parts of sucrose and 30 parts of water are mixed evenly, and then added to the dough mixer, kneaded into dough, and kneaded into a ball; Divide the dough into several portions of appropriate size, press them into the mold, and heat them to shape. The heat preservation temperature is 85°C, and the heat preservation time is 5 minutes. Keep the temperature at 120°C, pressurize once during the period, and apply a pressure of 80N; use a brush to evenly coat the tableware with a concentration of 2% rice flour gelati...

Embodiment 2

[0018] 60 parts of whole wheat flour, 5 parts of sorghum flour, 15 parts of rice flour, 10 parts of millet flour, and 10 parts of purple potato flour were subjected to microwave-assisted treatment and roasting pre-cooking treatment. The power of microwave-assisted treatment was 800W, and the time was 30S. The curing treatment power is 1800W, and the time is 0.5min; 5 parts of grain powder and butter, 2 parts of green tea powder, 1 part of chili powder, 2 parts of table salt and 40 parts of water after microwave-assisted treatment and pre-cooking treatment are mixed. Add it to the dough mixer, knead the dough, and knead it into a ball; divide the kneaded dough into several portions of appropriate size, press them into the mold, and heat them to shape. The heat preservation temperature is 65°C, and the heat preservation time is 10 minutes; Take the tableware out of the mold, put it into the baking tray for intermittent pressure baking, keep the temperature at 120°C, pressurize on...

Embodiment 3

[0020] 80 parts of whole wheat flour, 5 parts of sorghum flour, and 15 parts of rice flour were subjected to microwave-assisted treatment and dry-heat pre-cooking treatment. The microwave-assisted treatment power was 500W, the time was 120S, and the dry-heat pre-cooking treatment temperature was 100°C, and the time was 30min; Mix 3 parts of grain powder and butter, 2 parts of green tea powder, 1 part of chili powder, 1 part of sucrose and 30 parts of water after microwave-assisted treatment and dry heat pre-cooking treatment, add them to the dough mixer, and knead into dough. Knead the dough into a circle; divide the reconciled dough into several portions of appropriate size, press them into the mold, and heat them to shape. The heat preservation temperature is 85°C, and the heat preservation time is 5 minutes; Intermittent pressurized roasting, the temperature is kept at 120°C, pressurized once during the period, and the applied pressure is 80N; the tableware baked to nine mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com