Preparation method and application form of technological fake of composite skin

A composite material and composite material layer technology, which is applied in the field of preparation of process dummy parts, can solve problems such as being unfavorable for low-cost manufacturing of composite material skins, time-consuming and labor-intensive manufacturing, complex profiles, etc., and achieve reliable connection strength and structural form. Stable, easy-to-scratch finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

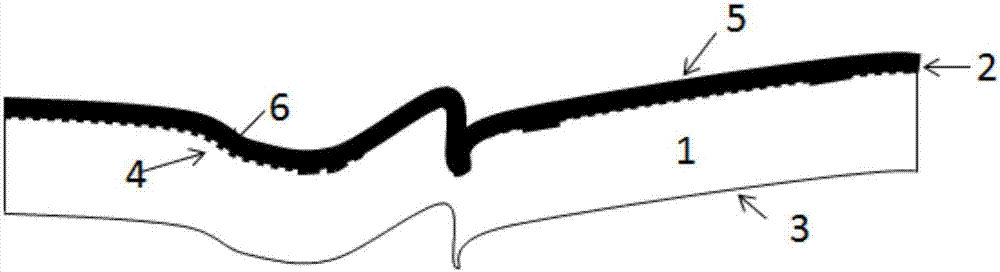

[0012] see figure 1 , a preparation method and application method of a process dummy of a composite material skin, characterized in that the process dummy comprises a composite material laminate 1 and an atomic ash layer 2, and the composite material laminate 1 is made of directional discontinuous prepreg Material preparation, the outer surface 4 of the composite material laminate is connected with the inner surface 6 of the putty layer, the inner shape surface 3 of the composite material laminate and the outer shape surface 5 of the putty layer constitute the inner surface and the outer surface of the process dummy respectively, And the surface structures of the inner and outer surfaces of the craft dummy are the same as those of the composite skin. The preparation method is as follows: (1) With the help of the composite material skin forming mold, according to the contour line of the composite material skin layer placed on the forming mold by the laser projection equipment, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com