Hydraulic device for sheets

A hydraulic device and plate technology, applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve problems such as column bending and affecting the guiding accuracy of moving beams, and achieve the effects of convenient movement, improved operating efficiency and economic benefits, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing:

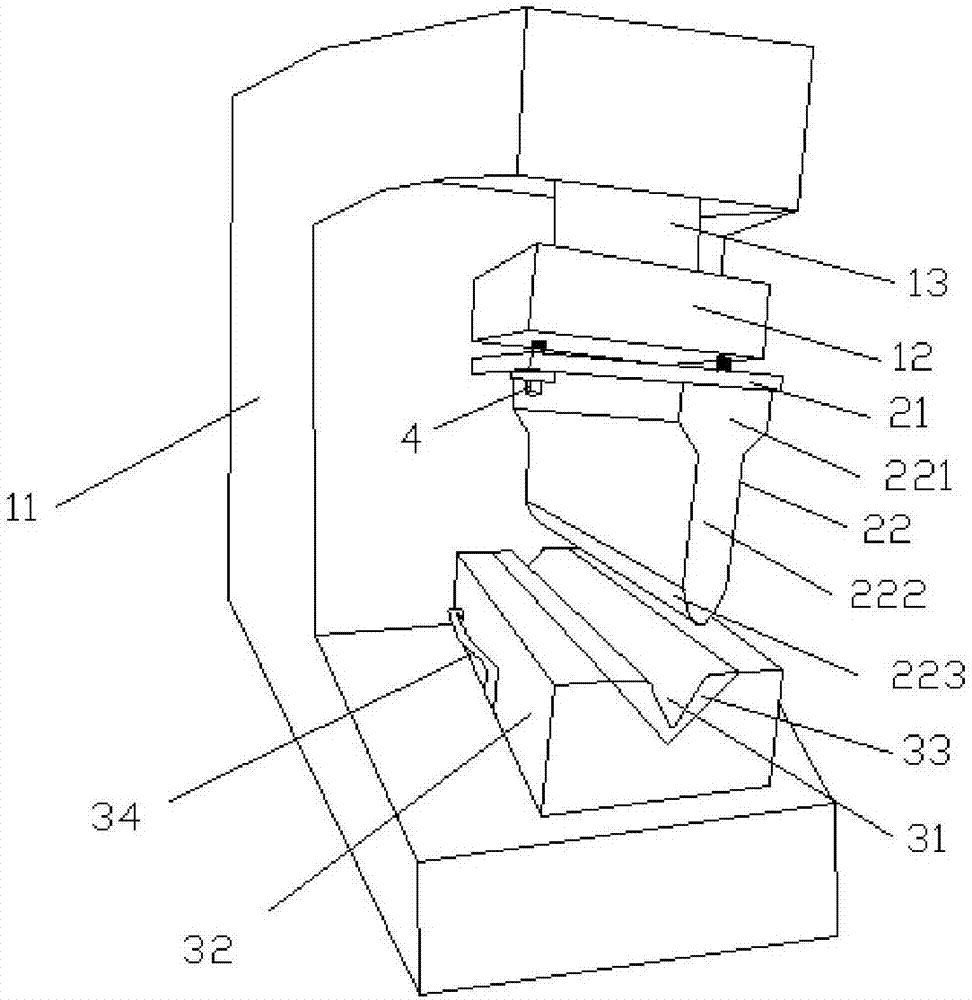

[0013] Such as figure 1 As shown, the plate hydraulic device in this embodiment includes a C-type hydraulic press and a stamping die installed on the hydraulic press. The hydraulic press includes a frame 11, a hydraulic main engine installed inside the frame 11, and a moving module 12 installed on the top of the frame 11. , the moving module 12 is connected with the hydraulic main engine through the hydraulic cylinder 13, and the hydraulic cylinder 13 can make the moving module 12 move up and down under the action of the hydraulic main engine; 4 is fixedly connected with the moving module 12. The lower side of the connection plate 21 is provided with a pressing plate 22 arranged along its width direction. The pressing plate 22 includes a fixed part 221, a connecting part 222 and a pressing part 223 connected in sequence. The cross section of the pressing part 223 is roughl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com