Vacuum hot water boiler ultralow in nitrogen emission

A hot water boiler, ultra-low nitrogen technology, applied in the field of steam furnaces, can solve the problems of high boiler furnace structure requirements, increased boiler manufacturing costs, and high burner prices, and achieves reduction of front and rear purging time, small flame, and boiler combustion efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

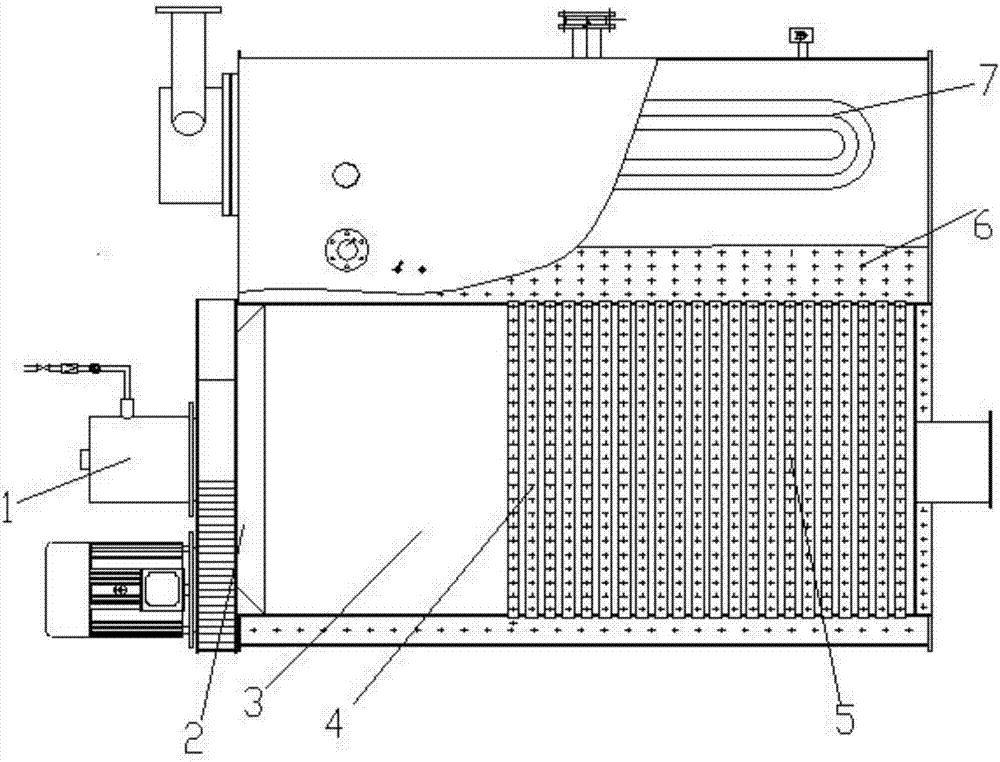

[0024] Please refer to the attached figure 1 As shown, the present invention is a vacuum hot water boiler with ultra-low nitrogen emissions that can effectively reduce nitrogen oxide emissions, which includes an ultra-low nitrogen burner, a gas distribution pipe, a furnace, a convective heat exchange tube, a finned condenser tube, Primary heat medium water, internal and external spiral tube group.

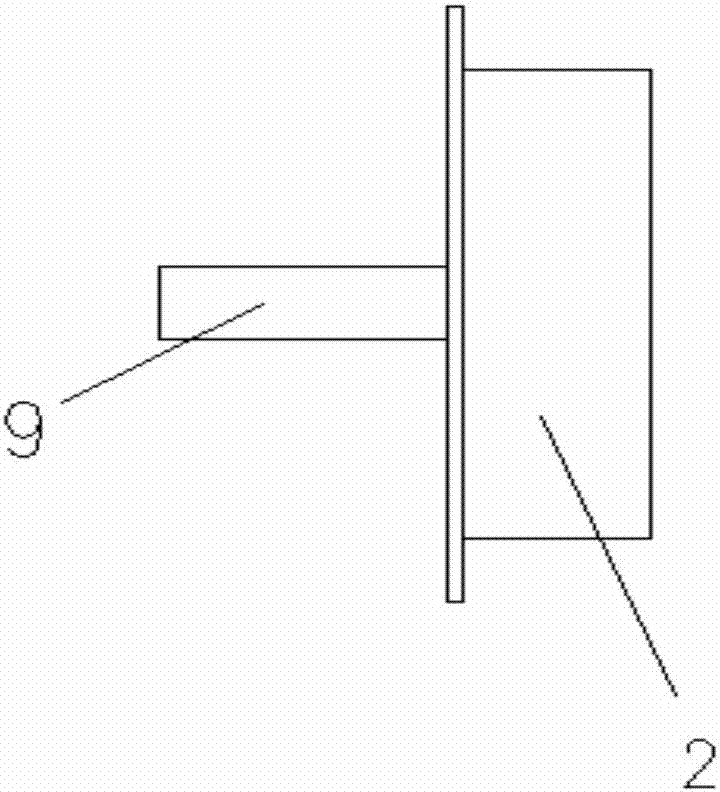

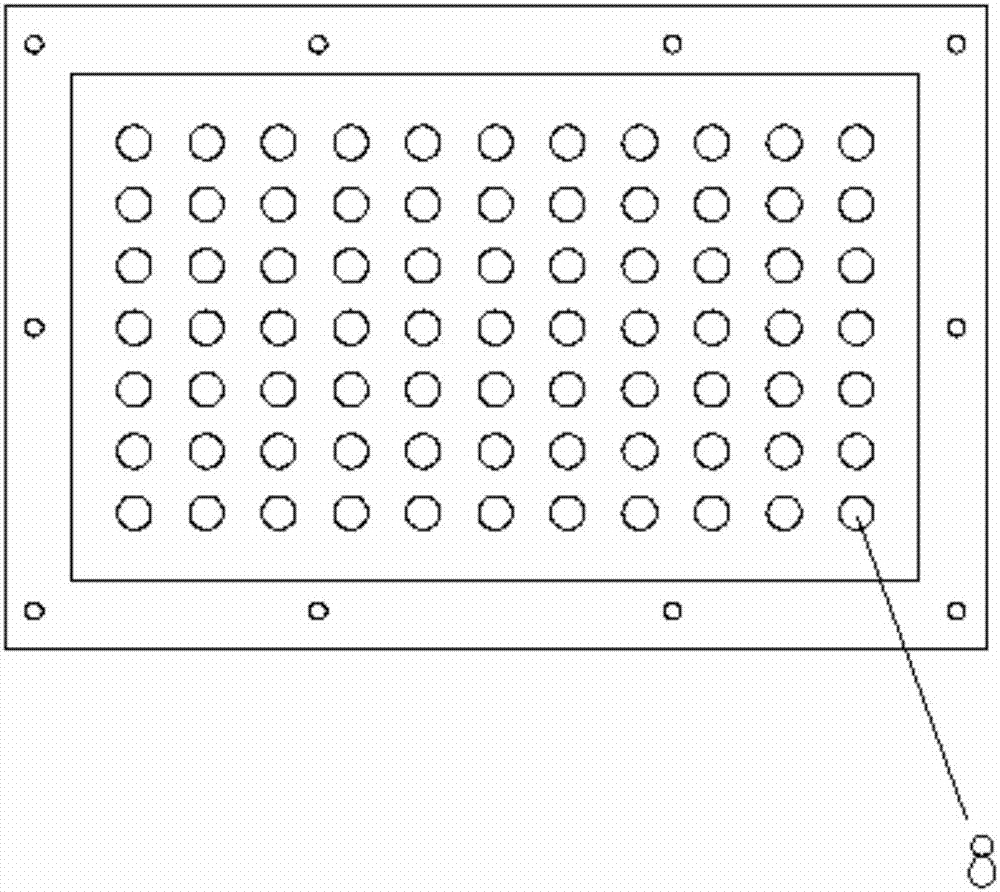

[0025] Such as figure 1 As shown, the present invention discloses a vacuum hot water boiler with ultra-low nitrogen emissions, including an ultra-low nitrogen burner 1, a gas distribution pipe 2, a furnace 3, a convective heat exchange pipe 4, a finned condenser pipe 5, and a primary heat medium Water 6, internal and external spiral tube group 7; wherein, the ultra-low nitrogen burner 1 is connected with a gas distribution pipe 2, and the convective heat exchange pipes 2 are arranged in a group in the combustion zone of the vacuum hot water boiler furnace 3, The area behind the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com