Manufacturing mold for irregular protolith structure surface test sample meeting indoor direct shear test requirements

A technology for test requirements and structural surfaces, applied in the engineering field, can solve problems such as the inability to directly carry out direct shear tests, difficulty in sample preparation of irregular original rock structural surfaces, and low resource utilization, and achieve simple and easy fabrication methods and easy disassembly , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

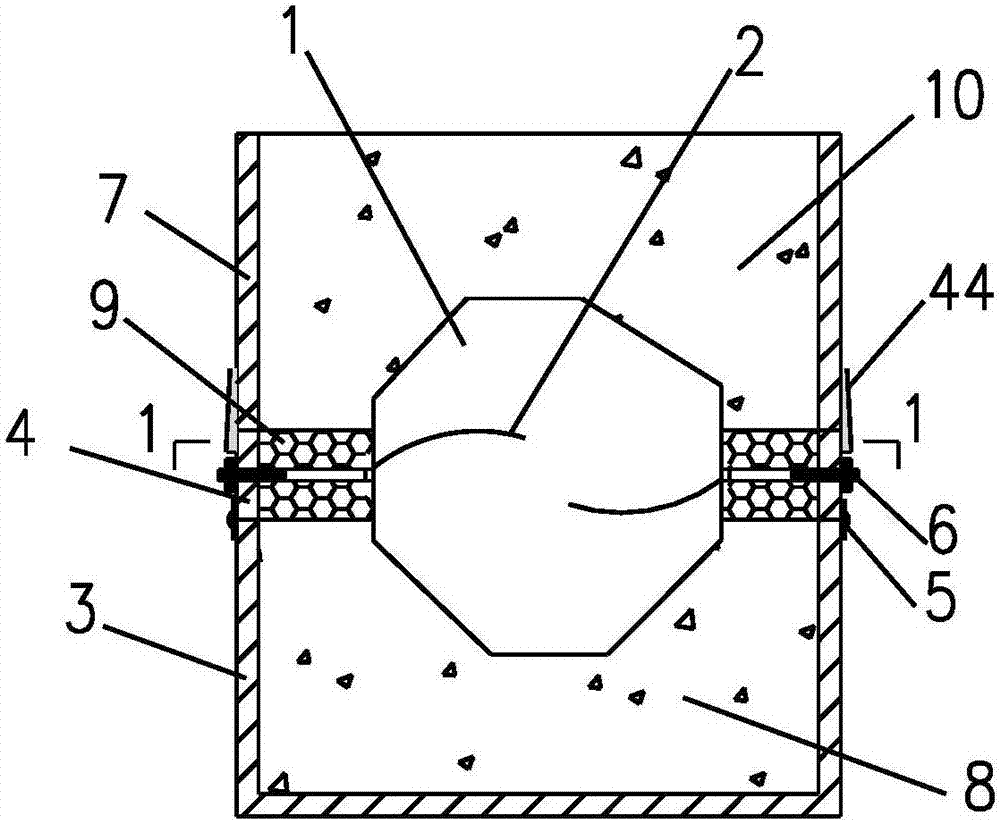

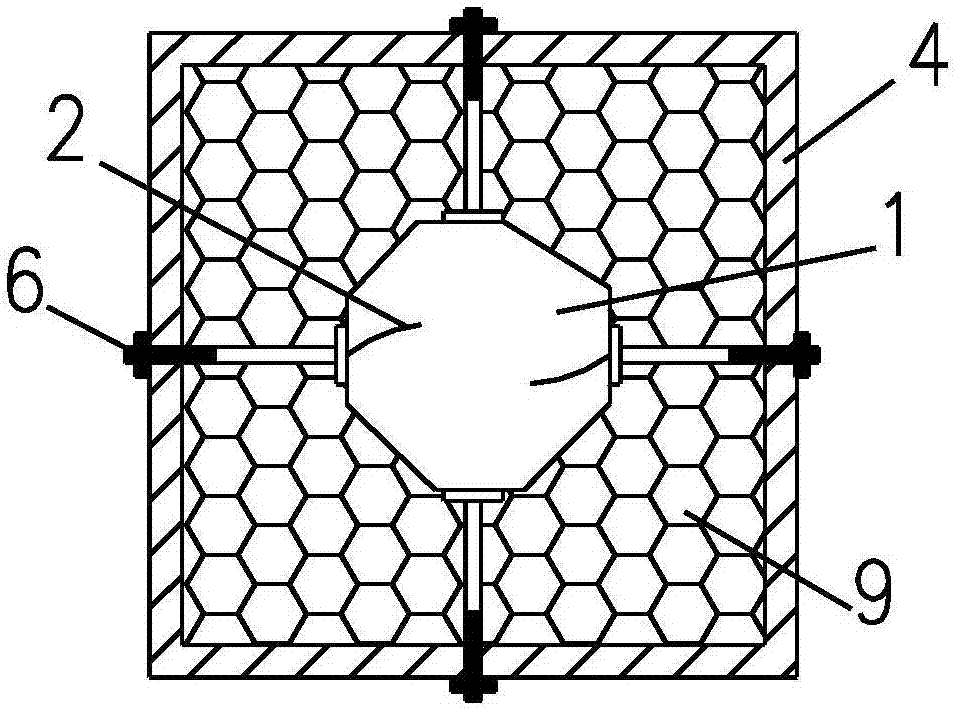

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

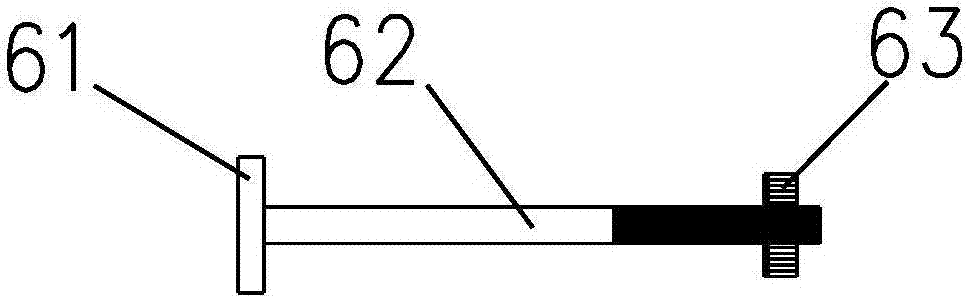

[0036] refer to Figure 1 to Figure 12 , a mold for making an irregular protorock structural surface sample that meets the requirements of a direct shear test, comprising a mold base plate 3, a mold base plate L-shaped side plate 31, a mold base plate L-shaped side plate connector 32, a mold base plate Bottom plate and side plate connecting piece 33, connecting piece 331, threaded rod 332, nut 333, connecting ear 334, bottom plate 34, mold mid-panel 4, mold mid-panel connecting plate 41, mold mid-panel connecting plate 42, mold mid-panel side Plate connector 43, mold upper plate positioning connector 44, hinge 5, original rock fixture 6, fixed end 61, threaded rod 62, nut 63, end rubber pad, mold upper plate 7, mold upper plate L-shaped side Plate 71, mold upper wall L-shaped side plate connector 72, rock sample foot wall filling layer 8, structural surface protection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com