Three-dimensional spacer fabric reinforced cement based composite material and preparation method and construction method thereof

A technology for spacing fabrics and reinforcing cement, which is applied in building materials, building material processing, building construction and other directions, can solve the problems of difficult operation of concrete construction methods and restrictions on concrete application, and achieves simple and easy preparation methods and construction methods. Effects of good flexibility and workability, excellent strength properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

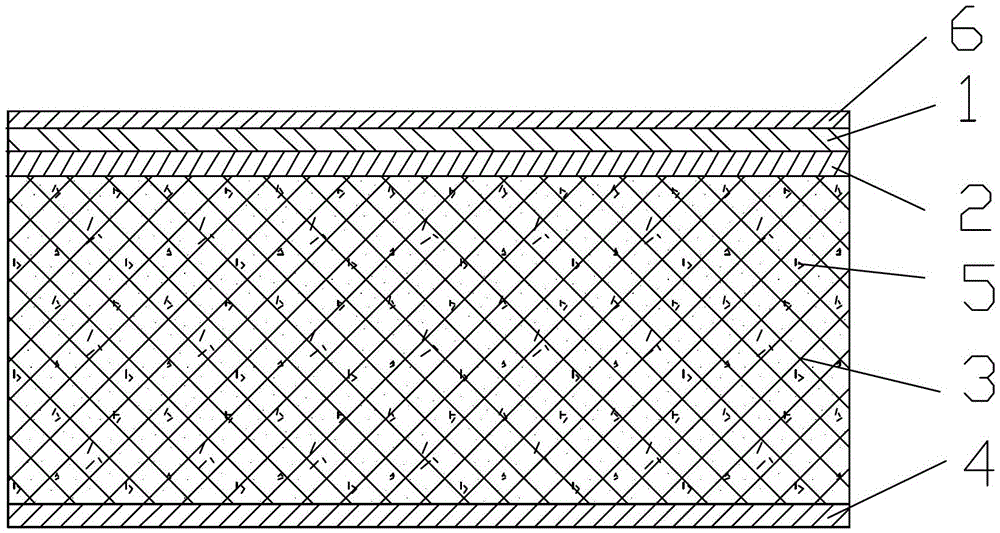

[0043] The preparation method of the above-mentioned three-dimensional spacer fabric reinforced cement-based composite material cloth includes the following steps:

[0044] The first step is to make a three-dimensional spacer fabric: First, select the raw materials of the upper woven fabric layer 2, the lower woven fabric layer 4 and the fiber yarn layer 3, and then use the warp knitting technology to weave the upper woven fabric layer 2, the lower woven fabric layer 4 For the three-dimensional spacer fabric composed of the fiber yarn layer 3, the hydraulic inorganic powder can pass through the mesh of the upper woven fabric layer 2, but cannot pass through the mesh of the lower woven fabric layer 4.

[0045] The second step is to fill the hydraulic inorganic powder: pour the hydraulic inorganic powder 5 into the top surface of the upper woven fabric layer 2 of the three-dimensional spacer fabric produced in the first step, and pass through the mesh of the upper woven fabric layer 2...

Embodiment 1

[0051] The preparation method provided by the present invention is used to prepare a three-dimensional spacer fabric reinforced cement-based composite material cloth, and the surface area of the composite material cloth is 2250 mm 2 The hydraulic inorganic powder 5 is made of sulphoaluminate cement. The three-dimensional spacer fabric is woven from flame-retardant polyester fiber yarn (PET fiber yarn). The thickness of the three-dimensional spacer fabric is 20mm, and the thickness of the sealing layer is 0.5mm. The thickness of the vinyl chloride waterproof membrane layer is 0.4mm. Subsequently, using the construction method provided by the present invention, water is sprayed on the surface of the lower woven fabric layer 4 of the composite material cloth to solidify and harden into a building component.

[0052] Place the building component in an environment with a temperature of 20±2℃ and a relative humidity of 60±5% for natural curing. After curing for 10 days, test the compr...

Embodiment 2

[0055] The preparation method provided by the present invention is used to prepare a three-dimensional spacer fabric reinforced cement-based composite material cloth, and the surface area of the composite material cloth is 2250 mm 2 The hydraulic inorganic powder 5 is made of high-alumina cement. The three-dimensional spacer fabric is woven from flame-retardant polyester fiber yarn (PET fiber yarn). The thickness of the three-dimensional spacer fabric is 15mm, and the thickness of the sealing layer is 0.5mm. Polyvinyl chloride The thickness of the waterproof membrane layer is 0.4 mm. Subsequently, using the construction method provided by the present invention, water is sprayed on the surface of the lower woven fabric layer 4 of the composite material cloth to solidify and harden into a building component.

[0056] Place the building component in an environment with a temperature of 20±2℃ and a relative humidity of 60±5% for natural curing. After curing for 10 days, test the com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com