Pressure relief type deepwater environment simulated explosion testing device

An explosion test and pressure relief technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high test cost, large volume, and wall thickness of the device, and achieve the goal of reducing test difficulty, reducing equipment cost, and high carrying capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

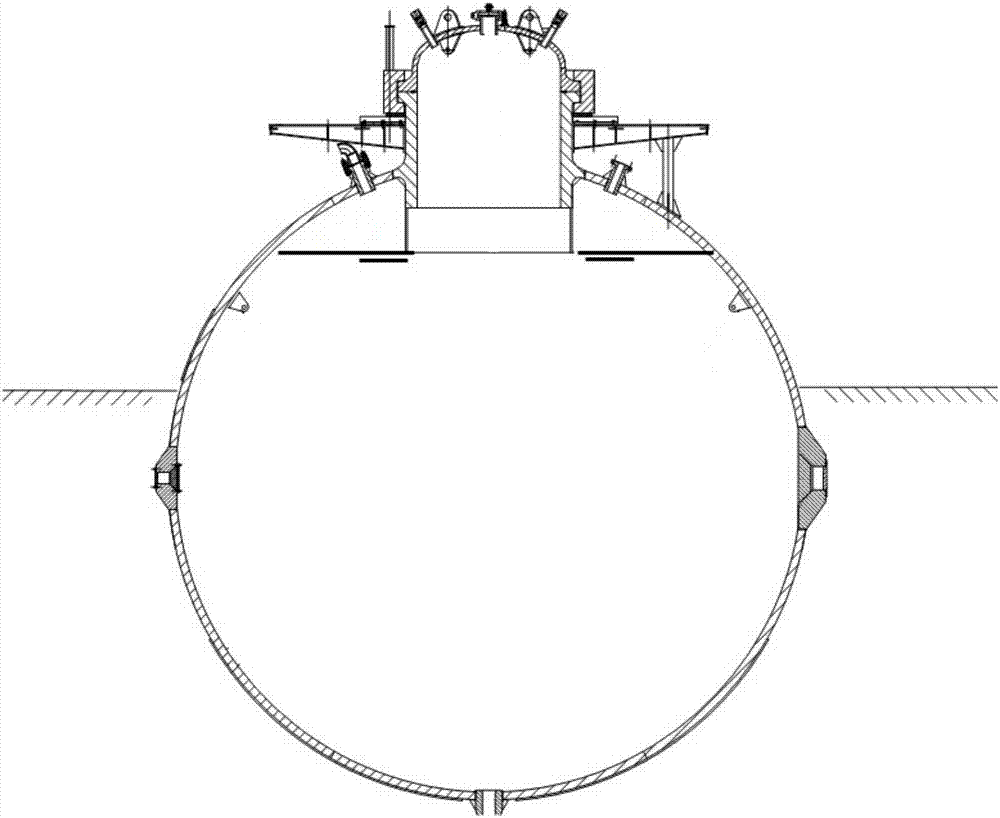

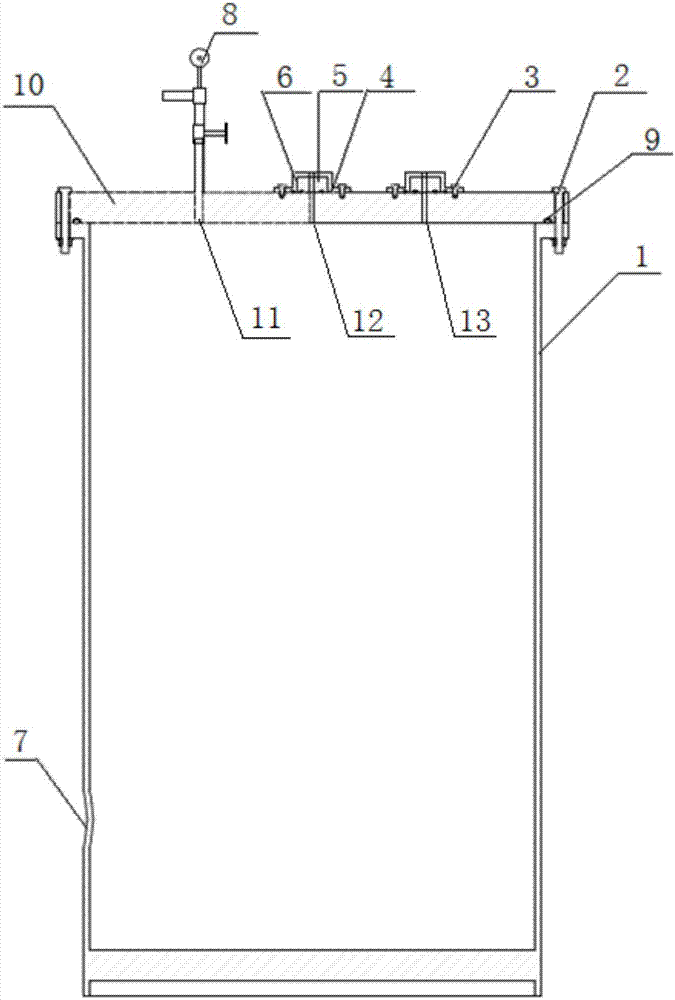

[0020] see figure 2 , the present embodiment is a pressure relief type simulated deep water environment explosion test device, its structure includes a pressure vessel 1 with an open top, and a pressurization hole 7 is arranged on the side of the pressure vessel 1, which is connected to an electric booster pump for pressurization. The pressure vessel 1 is a cylindrical vessel. After the vessel is filled with water, a pressure relief flange 10 is installed on the top, and the pressure relief flange 10 is fixed to the pressure vessel 1 by the pressure relief flange bolts 2 . A pressure relief flange sealing groove 9 is provided on the contact surface between the pressure relief flange 10 and the pressure vessel 1 , and a sealing ring is installed in the pressure relief flange sealing groove 9 .

[0021] The pressure relief flange 10 is provided with a static pressure measurement hole 11 , a shock wave pressure measurement hole 12 and an initiation hole 13 . A pressure gauge 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com