Preparation method of quasi-solid electrochromic device

An electrochromic device and electrochromic technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of few reports on the preparation process of quasi-solid-state electrochromic devices, so as to avoid the influence of device performance and stabilize the process , The effect of high controllability of finished product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

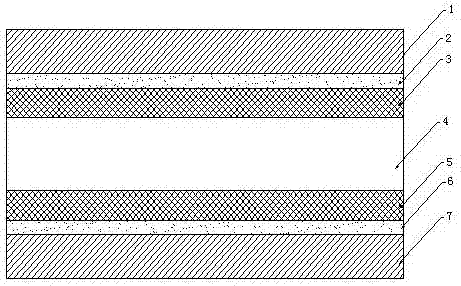

[0034] The preparation method of the quasi-solid-state electrochromic device of the present invention, such as figure 1 As shown, the device is sequentially composed of a first substrate 1, a first transparent conductive layer 2, an electrochromic layer 3, an ion transport layer 4, an ion storage layer 5, a second transparent conductive layer 6 and a second substrate 7; The preparation method comprises the following steps:

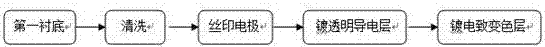

[0035] (1) Prepare the first functional substrate, such as figure 2 as shown,

[0036] Step 1: Use a clean and highly transparent material as the first substrate 1, and form a conductive silver paste with a thickness of 300-400 um on the surface of the first substrate 1 through a silk screen printing process, as an electrode, and then uniformly spread the conductive silver paste on the surface of the conductive silver paste Deposit a layer of transparent conductive film with a film thickness of 20-400nm to form the first transparent conductive layer 2; ...

Embodiment 1

[0056] The preparation method of the PMMA / PVB gel quasi-solid-state electrochromic device containing lithium ions in this embodiment comprises the following steps:

[0057] (1) Preparation of the first functional substrate:

[0058] Step 1: Use clean plexiglass as the first substrate 1, and form a conductive silver paste with a thickness of 300-400 um on the surface of the first substrate 1 through a silk screen printing process as an electrode. The screen printing process uses a 200-mesh screen printing screen cloth, the distance between the screen printing mesh and the first substrate is 2-4mm, and the screen printing pressure is 1.5-3bar; then a layer of transparent conductive film with a film thickness of 20-400nm is evenly deposited on the surface of the conductive silver paste by vacuum coating process, and the deposition The temperature is 350-380°C, the deposition power is 12-14kw.h, the transmission speed is 0.8-1.2m / min, and the reaction pressure is 0.5-0.6pa to form...

Embodiment 2

[0071] The preparation method of the PMMA / PVB gel quasi-solid-state electrochromic device containing lithium aluminum ions in this embodiment comprises the following steps:

[0072] (1) Preparation of the first functional substrate:

[0073] Step 1: Use clean plexiglass as the first substrate 1, and form a conductive silver paste with a thickness of 300-400 um on the surface of the first substrate 1 through a silk screen printing process as an electrode. The screen printing process uses a 200-mesh screen printing screen cloth, the distance between the screen printing mesh and the first substrate is 2-4mm, and the screen printing pressure is 1.5-3bar; then a layer of transparent conductive film with a film thickness of 20-400nm is evenly deposited on the surface of the conductive silver paste by vacuum coating process, and the deposition The temperature is 350-380°C, the deposition power is 12-14kw.h, the transmission speed is 0.8-1.2m / min, and the reaction pressure is 0.5-0.6p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com