Three-dimensional negative stiffness honeycomb structure and preparation method thereof

A honeycomb structure, negative stiffness technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of limiting the recoverability of the honeycomb structure, limiting the energy absorption, limiting the reuse of the honeycomb structure, etc. Sexual energy absorption, energy absorption enhancement, effect with initial stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

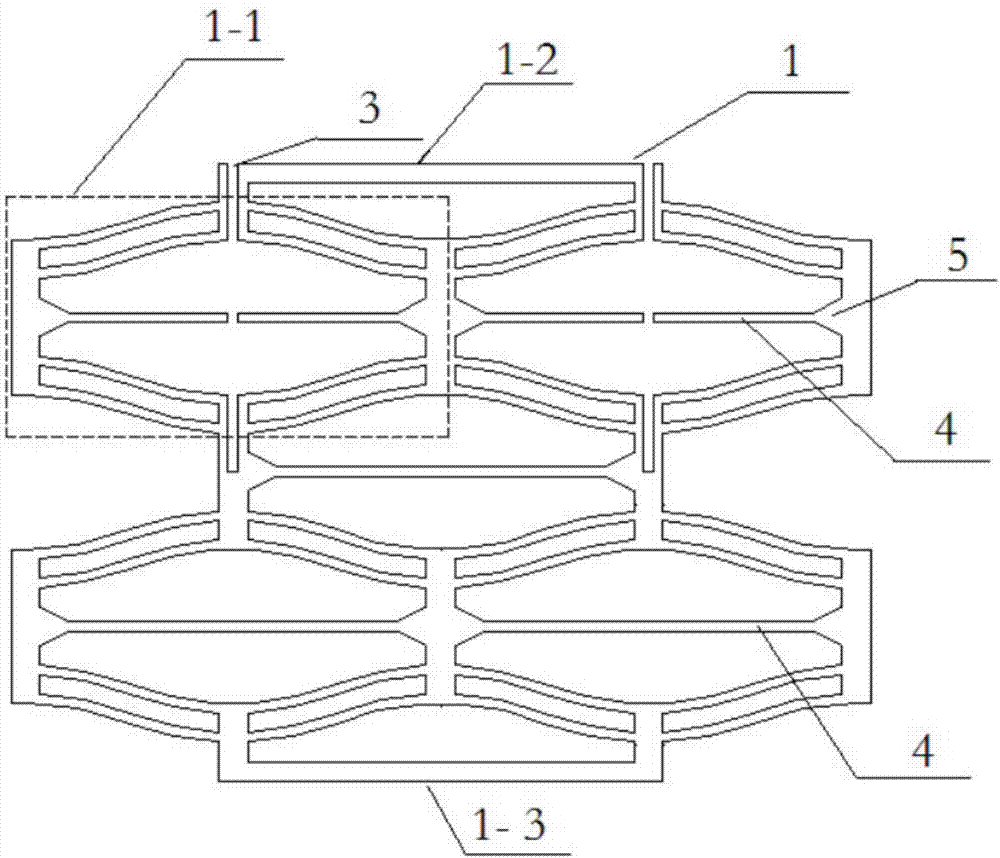

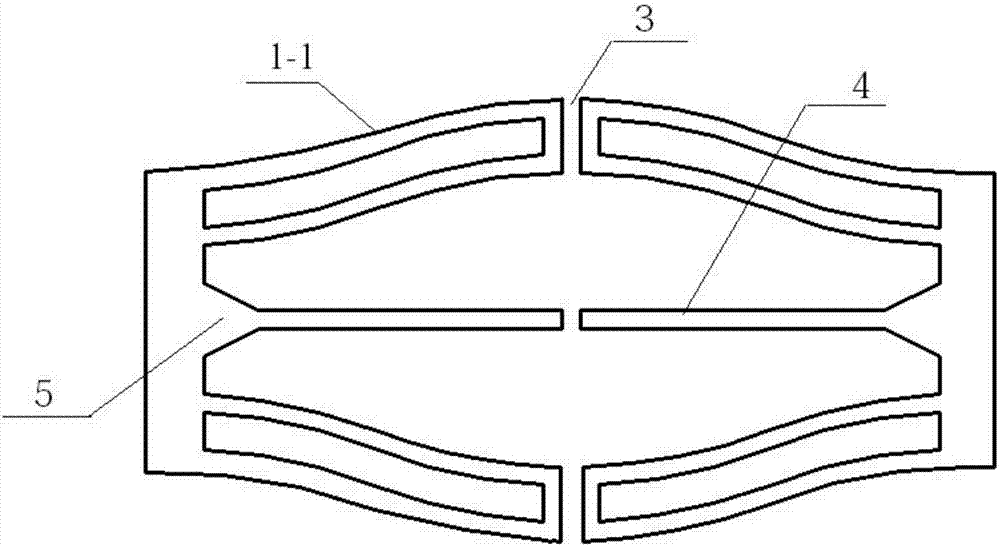

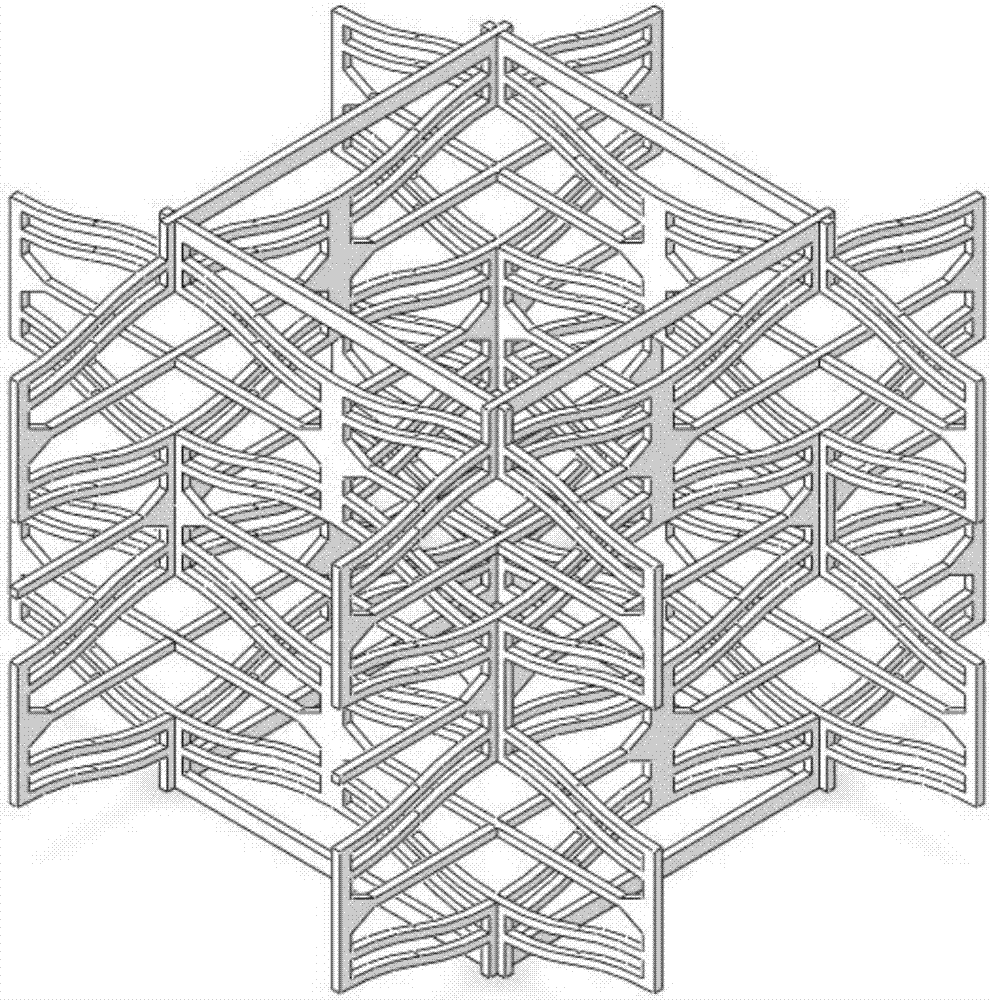

[0031] Specific implementation mode one: combine Figures 1 to 4 Describe this embodiment, the three-dimensional negative stiffness honeycomb structure of this embodiment, it is interlocked together by four inserts 1, has formed three-dimensional negative stiffness honeycomb structure; The four inserts 1 all have interlocking notches 3. The width of each interlocking notch 3 is equal to the thickness of the insert 1, and the thickness of the four inserts 1 is the same; two of the four inserts 1 are defined as column groups, and the other two are defined as row groups. The interlocking notch 3 of the group and the interlocking notch 3 of the row group are embedded together to form a three-dimensional negative stiffness honeycomb structure;

[0032] The insert 1 is composed of five hollow "hexagonal" units 1-1, an upper beam 1-2 and a lower beam 1-3;

[0033] Wherein, the left and right sides of each "hexagonal" unit 1-1 are parallel to the vertical line;

[0034] One side of ...

specific Embodiment approach 2

[0040] Specific implementation mode two: combination Figures 1 to 4 This embodiment is described. The difference between this embodiment and the specific embodiment 1 is that the "hexagonal" unit 1-1 is grooved on the upper and lower sides. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0041] Specific implementation mode three: combination Figures 1 to 4 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is: the upper and lower four sides of the "hexagonal" unit 1-1 are "wave-shaped", and the upper parts of the upper two sides are convex arc-shaped sides , the lower part is a concave arc-shaped side, and the lower two sides and the upper two sides are arranged symmetrically with the transverse axis of the "hexagonal" unit 1-1.

[0042] Other compositions and connection methods are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com