Oblique hole etching method

An oblique hole and lateral etching technology, applied in the field of microelectronics, can solve the problems of serious depression, oblique hole inclination angle or shape damage, inability to precisely eliminate the depression, etc., and achieve the effect of smooth sidewall and ideal inclination angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the technical solution of the present invention, the oblique hole etching method provided by the present invention will be described in detail below with reference to the accompanying drawings.

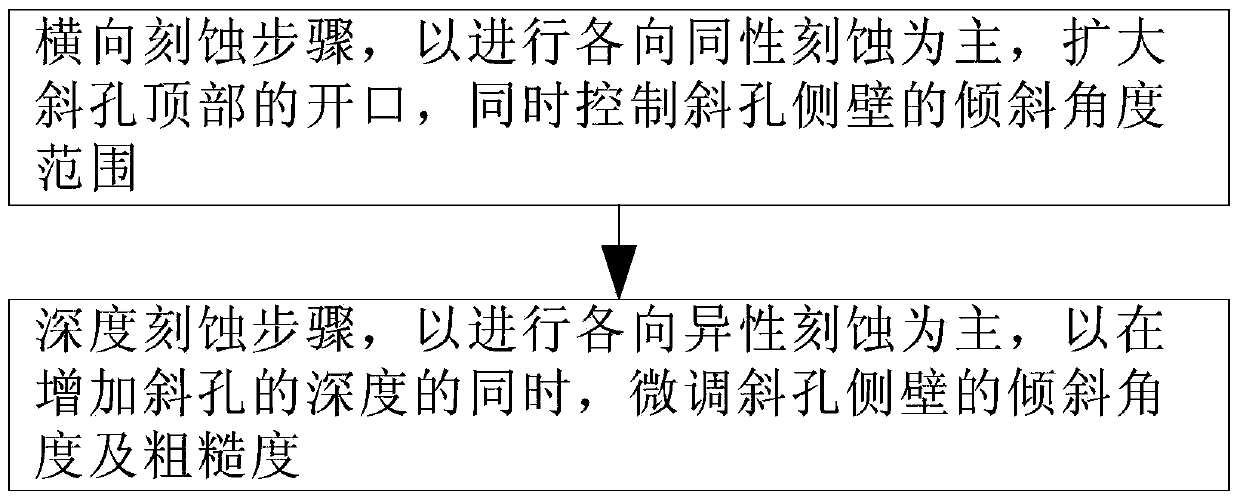

[0037] figure 1 A flow chart of the oblique hole etching method provided by the present invention. see figure 1 , the oblique hole etching method provided by the present invention comprises the following steps:

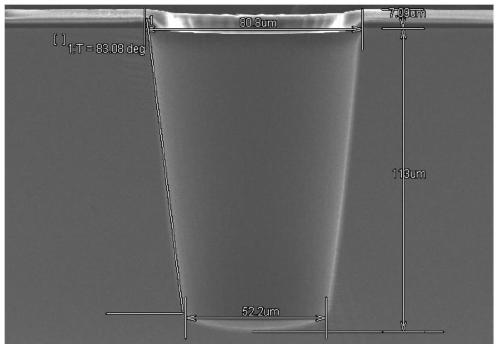

[0038] The lateral etching step is mainly to perform isotropic etching, expand the opening at the top of the inclined hole, and control the inclination angle range of the side wall of the inclined hole at the same time;

[0039] The depth etching step mainly performs anisotropic etching to fine-tune the inclination angle and roughness of the sidewall of the inclined hole while increasing the depth of the inclined hole.

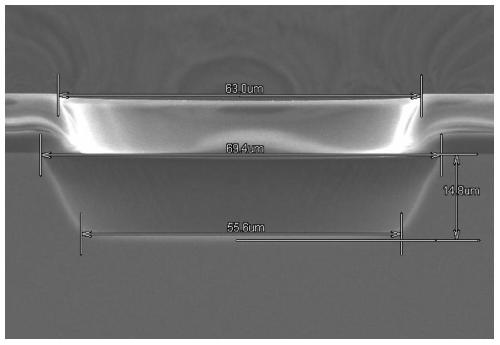

[0040] The main reason for the defect of the top depression (bowing) of the side w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com