Wing box microgroove heat pipe heat collecting plate, composed shutter flat-plate solar heat collector and application

A heat collecting plate and heat collector technology, applied in solar heat collectors, solar heat collectors using working fluid, solar thermal energy, etc. Problems such as large thermal resistance, to achieve the effect of simplifying the manufacturing process, improving heat collection efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

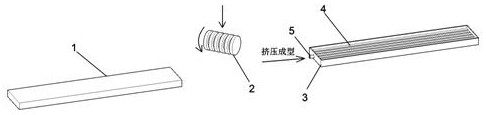

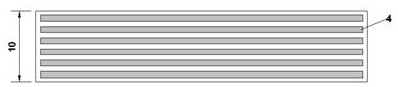

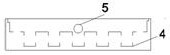

[0032] Embodiment 1, with reference to Figure 4 , a wing box micro-groove heat pipe heat collector plate, copper, aluminum and other metal billets are extruded to form a micro-groove heat pipe box, and then connected with the metal base material of the solar radiation heat absorbing plate as the heat pipe box packaging surface by extrusion It is sealed and molded, and the working fluid vacuum / injection tube reserved on the heat pipe box is evacuated and filled with heat pipe heat exchange fluid to make a wing box micro-groove heat pipe heat collector plate; the surface of the solar radiation heat absorption plate is coated with solar energy selection After absorbing the film, it is used as a heat collector plate for solar radiation light-to-heat conversion, thus forming a wing box micro-groove heat pipe heat collector plate that integrates heat absorption and heat transfer.

[0033] The micro-groove heat pipe of the wing box is divided into an evaporation section, an adiabati...

Embodiment 2

[0041] Embodiment 2, with reference to Figure 9 , a louvered flat-plate solar heat collector composed of wing box micro-groove heat pipe heat collector plates, including a heat exchange heat sink or heat exchange device, and the wing box micro-groove heat pipe solar heat collector plates are used according to the required angle and heat exchange The heat sink or heat exchange device is connected to form a louvered flat solar collector.

[0042] The louver structure of the above-mentioned louvered flat-plate solar collector, which consists of wing box micro-groove heat pipe collector plates as louvers, belongs to the honeycomb structure of the flat-plate collector cover plate. According to the numerical simulation and analysis of the transient thermal performance of the louver-type solar collector It was found that the louvered collector can reduce the heat loss of the collector plate cover by 5% by inhibiting the air convection in the collector cavity.

[0043] The wing box ...

Embodiment 3

[0044] Embodiment 3, the application of a louvered flat solar collector composed of wing box microgroove heat pipe heat collector plates, the louvered flat solar collector can Embedded parts are installed and fixed, or the hanging board on the louver flat solar structure frame is connected and fixed with the building facade structure, and it is easy to arrange vertically on the building facade, replacing the shading, shading, decorative functions of the building's external louvers and building solar heat. Take advantage of the unity of functions.

[0045] Production process of the present invention:

[0046] The core of the present invention is that after the wing box micro-groove heat pipe louver heat collector is made by extrusion process, the required mode louver flat solar collector can be made according to the requirements of use scale, installation conditions and connection device form. details as follows:

[0047] Step 1: Calculate and determine the structural paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com