PCB manufacturing method for conveniently detecting back drilling hole precision

A manufacturing method and back-drilling technology, applied in printed circuit manufacturing, circuit inspection/identification, and electrical connection formation of printed components, etc., can solve the problem of X-ray failure to illuminate the offset, back-drilling offset, drilling and disconnecting lines and other problems, to achieve the effect of saving detection costs and labor costs, improving work efficiency, and convenient and simple accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

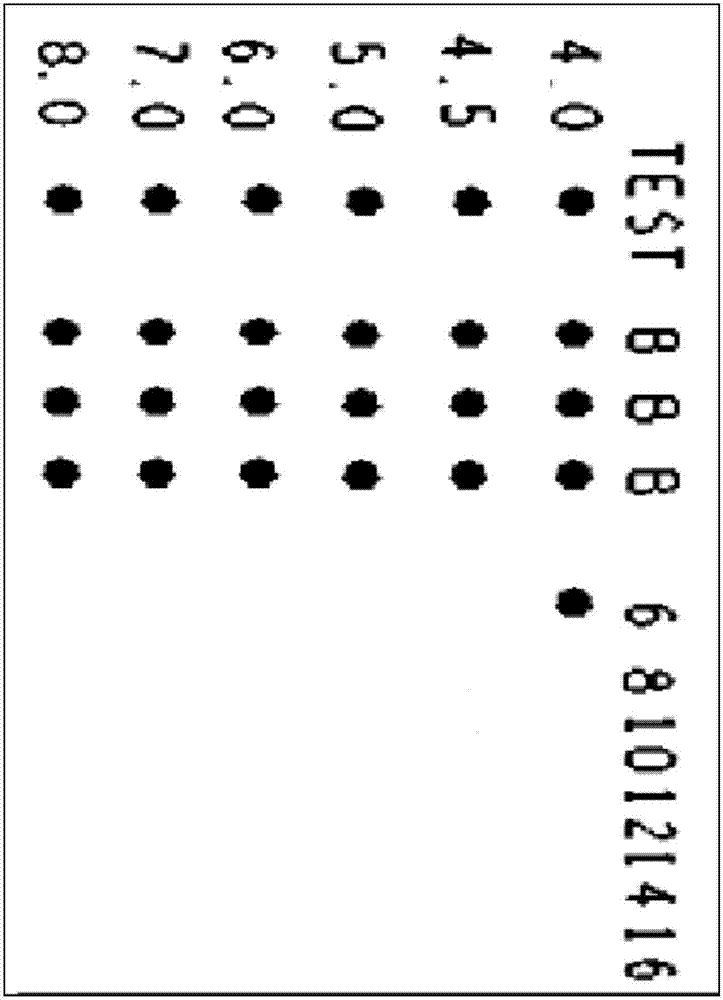

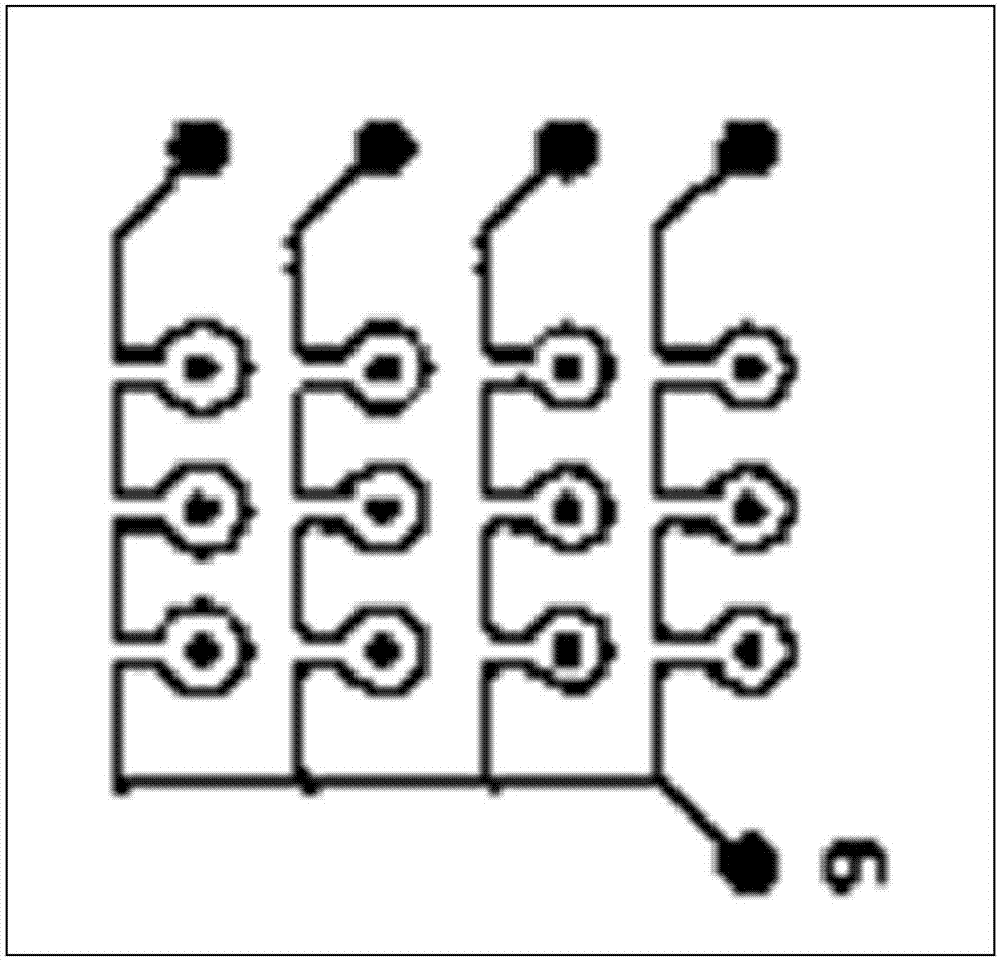

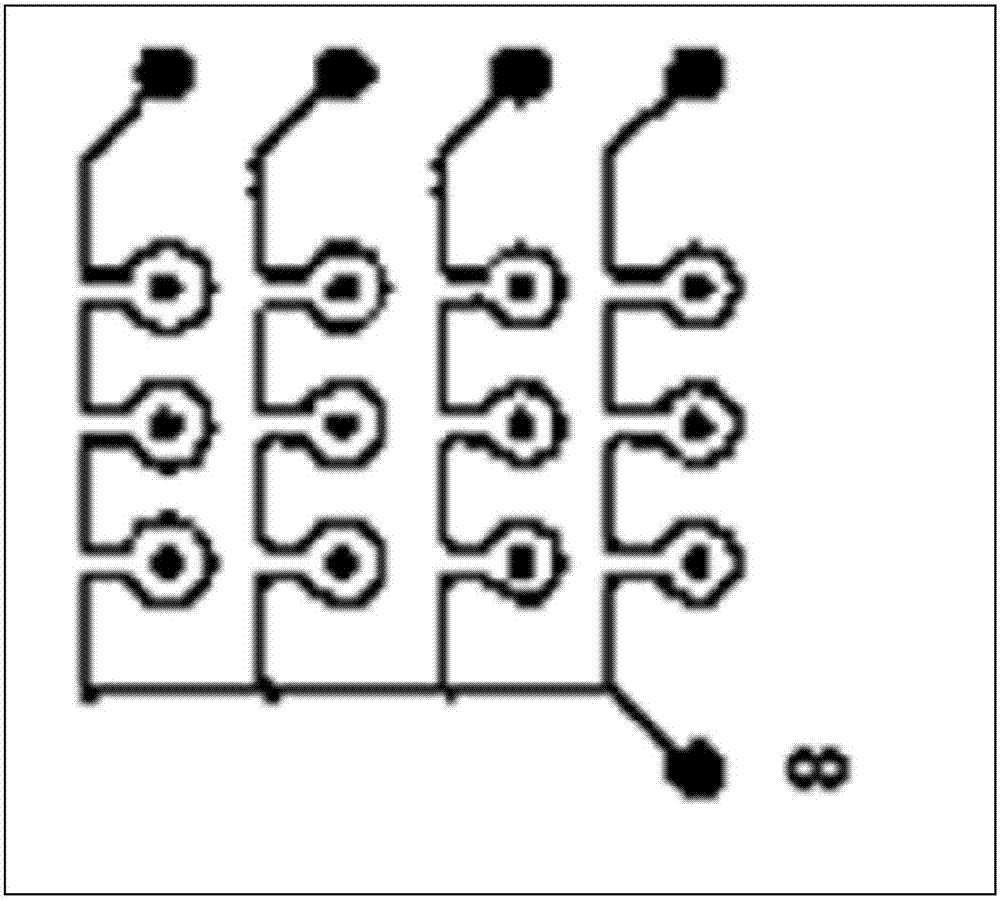

[0026] refer to Figure 1 to Figure 3 , the present invention provides a kind of method for making the PCB that is convenient to detect back drilling accuracy, and concrete steps are as follows:

[0027] According to the existing technology, the substrate is made into a production board with an outer circuit by successively cutting the material → negative film process to make the inner layer circuit → pressing → drilling → sinking copper → full board electroplating → positive film process to make the outer layer circuit. details as follows:

[0028] a. Cutting: Cut out the core board according to the panel size 520mm×620mm, and the thickness of the core board is 0.5mm H / H.

[0029] b. Inner layer circuit (negative film process): produced by vertical coating machine, the film thickness is controlled to 8μm, and a fully automatic exposure machine is used to complete the exposure of the inner layer circuit with 5-6 grid exposure rulers (21 grid exposure rulers), and then etch af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com