Catalyst for catalytic decomposition of n2o monopropellant and its preparation method and application

A catalytic decomposition and catalyst technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. Unable to continue to use etc.

Active Publication Date: 2011-11-30

DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Catalytic decomposition of dinitrogen at low temperature conditions, such as spinels, molecular sieves, etc., but these catalysts cannot tolerate dinitrogen

hair, resulting in a significant reduction in catalyst activity, can not continue to use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

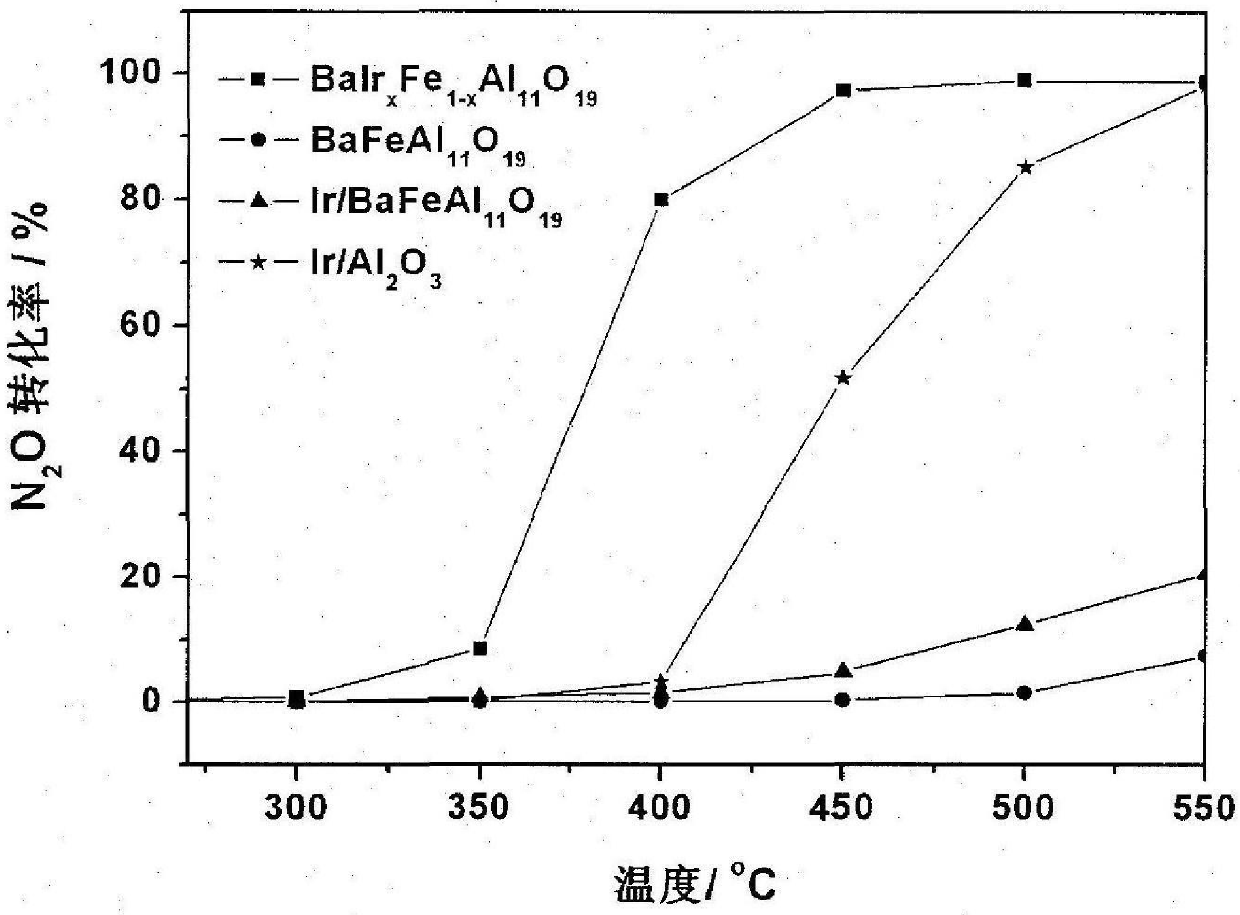

The invention relates to a catalyst for catalytic decomposition of N2O monopropellant and its preparation and application. It is a hexaaluminate with a molecular formula of BaIrxFe1-xAl11O19 or SrIrxMn1-xAl11O19, x represents the substitution amount of iridium as an active material, and the mass percentage of iridium in the hexaaluminate is 5%. The catalyst prepared by applying this method can realize the catalytic decomposition of nitrous oxide single-component propellant at low temperature, and can withstand the high-temperature and high-oxygen gas generated by the decomposition of nitrous oxide. The catalytic decomposition of the agent has high activity, high stability and repeated starting performance.

Description

for N 2 Catalyst for the catalytic decomposition of O monopropellant and its preparation method and application technical field What the present invention relates to is a kind of propellant (Nitrousoxide) for nitrous oxide monopropellant monopropellant) catalytic decomposition of new hexaaluminate catalysts and their preparation and application. Catalysts prepared by this method The oxidizing agent can make the nitrous oxide single-component propellant realize catalytic decomposition at a relatively low temperature (300 ° C ~ 350 ° C), and And it can withstand the high temperature (1000℃~1400℃) high-oxygen gas produced by the decomposition of nitrous oxide. The catalytic decomposition of the meta-propellant has high activity, high stability and repeated starting performance. Applicable to gas generators, aircraft attitude control etc. Background technique [0002] New types of small satellites require advanced propulsion systems. Such a system should meet th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01J23/00B01J37/03

Inventor 朱少敏张涛王晓东王爱琴丛昱吕飞程鸿魁

Owner DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com